Installation – Commissioning a T50/T100 PTM

T50/T100 PTM – User Guide – Version 2 Issue 1

22

Caution: Failure to open the Ink-Vent-Screw will lead to print failure or damage to

the print head. Make sure it is open!

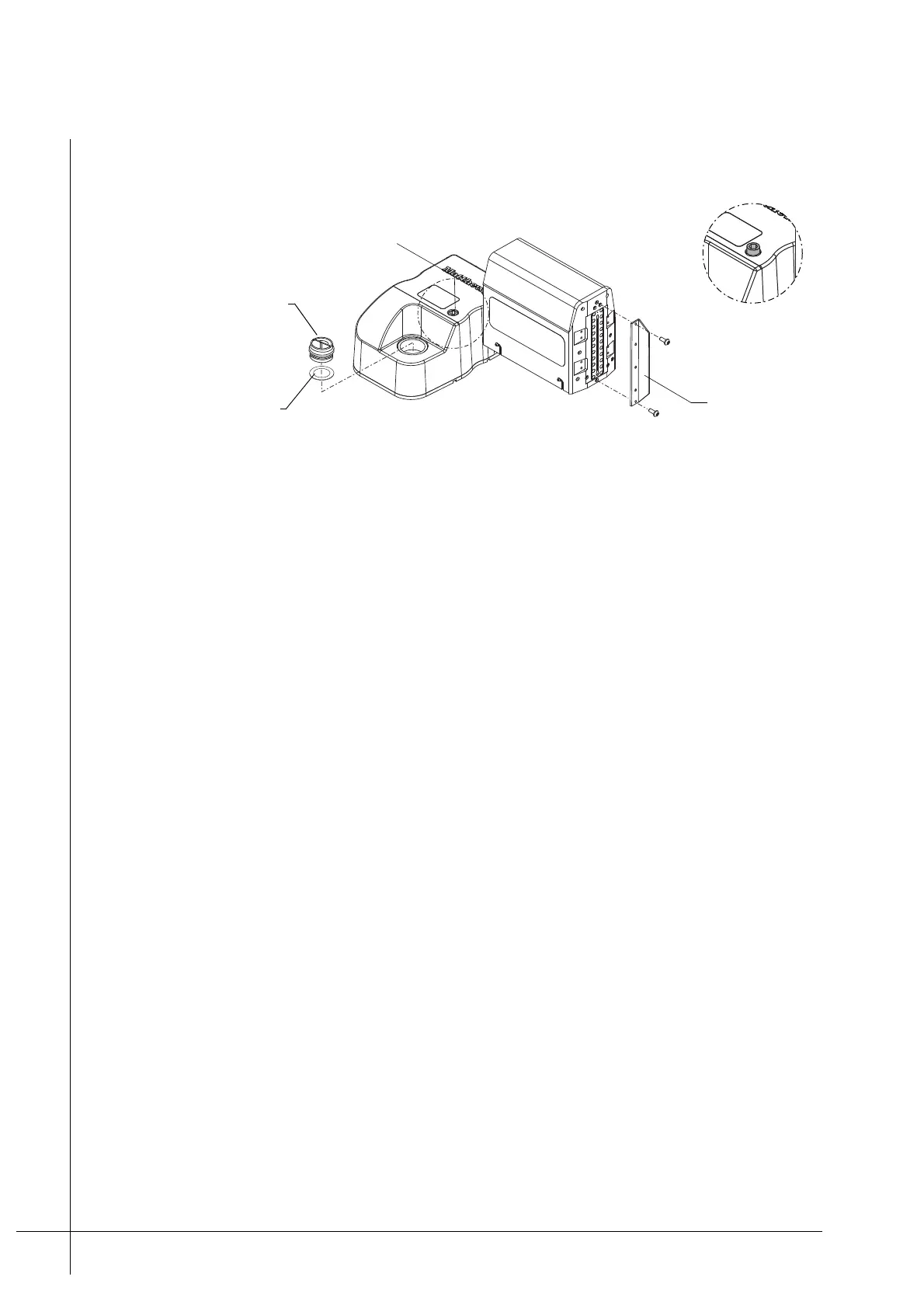

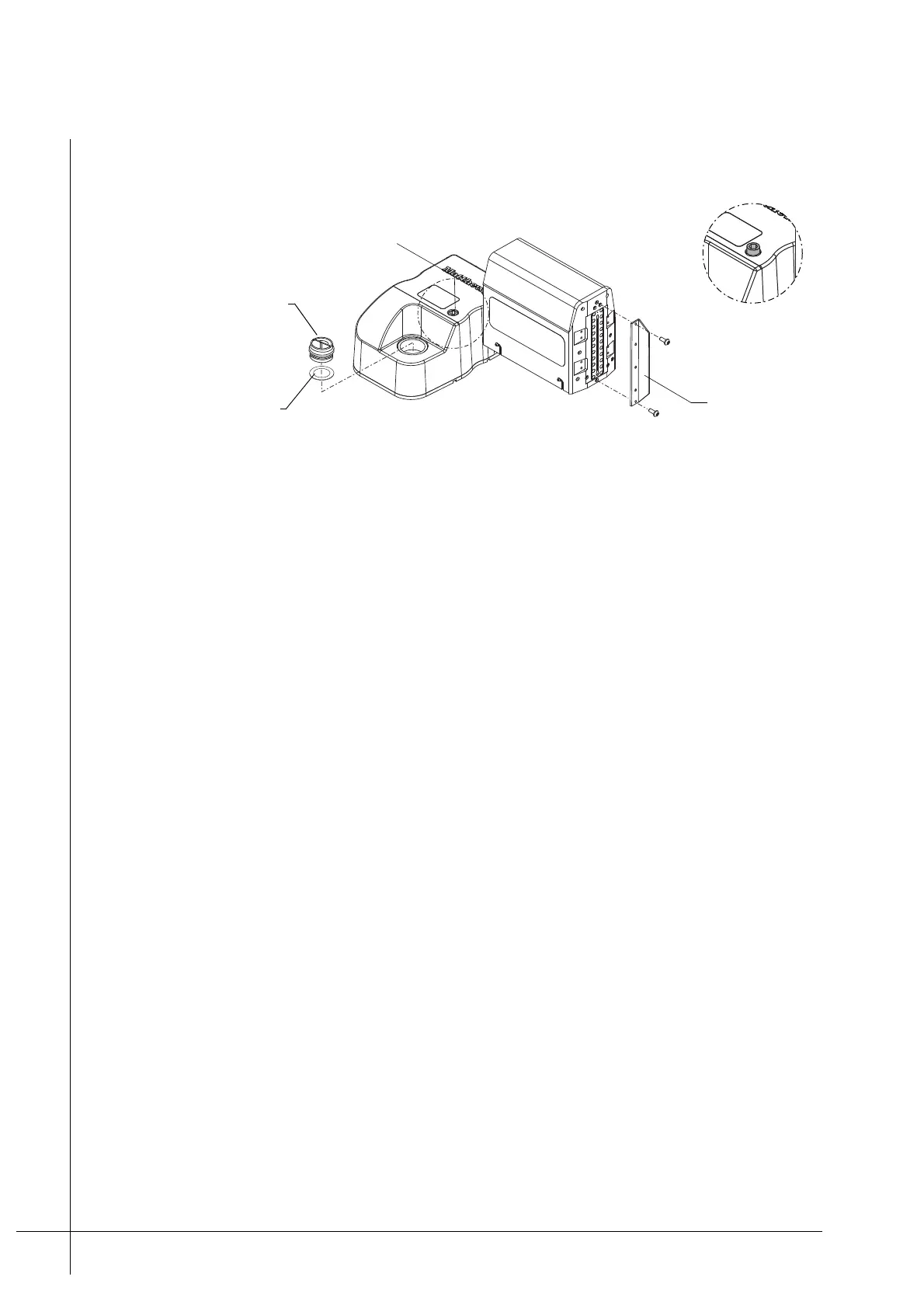

Figure 20 - Nozzle-Protector-Plate

3. Unscrew and remove the Nozzle-Protector-Plate from the front of the print head, as

shown above. Store it in a clean place for future use.

4. Unscrew and remove the Ink-Reservoir-Cap from the Ink-Inlet. Store it in a clean place

for future use.

5. Make sure that the Ink-Inlet-Seal, inside the Ink-Inlet, is clean and correctly seated.

6. Put a new Ink-Bottle into the Ink-Inlet as described under “Ink-Bottle Replacement” on

page 28.

7. Connect an encoder/photocell to the back of the print head, as required.

8. Connect the print head(s) to the RJ-45 connector that ia labelled "Printer Network" on

the PCM’s interface panel. A single print head can either be connected directly or via a

dedicated Viacode Ethernet switch.

If more than one print head is installed, they must be connected to a dedicated Viacode

Ethernet switch first, which in turn is connected to the PCM.

9. Connect the print head’s Power-Supply-Pack to the DSUB connection that is labelled

Power on the back of the print head. Connect the Power-Supply-Cable between the

Power-Supply-Pack and a mains outlet supply. Make sure that the correct power is

supplied to the print head.

Note: The Power-Supply-Pack and the Power-Supply-Cable are sold separately to the

PTM.

10. Wait until the READY LED on the back of the print head illuminates green.

Note: The READY LED will illuminate green when the print head has reached the correct

operating temperature, which takes approximately two minutes. It will illuminate orange

while warming up.

Ink-Reservoir-Cap

Ink-Vent-Screw

Nozzle-

Protector-Plate

Detail A

A

Ink-Inlet-Seal

A

Loading...

Loading...