Appendix – Troubleshooting

T50/T100 PTM – User Guide – Version 2 Issue 1

36

Examples of Poor Print Quality

Provided below is a list of poor print quality examples. The possible cause for the poor print

is also listed.

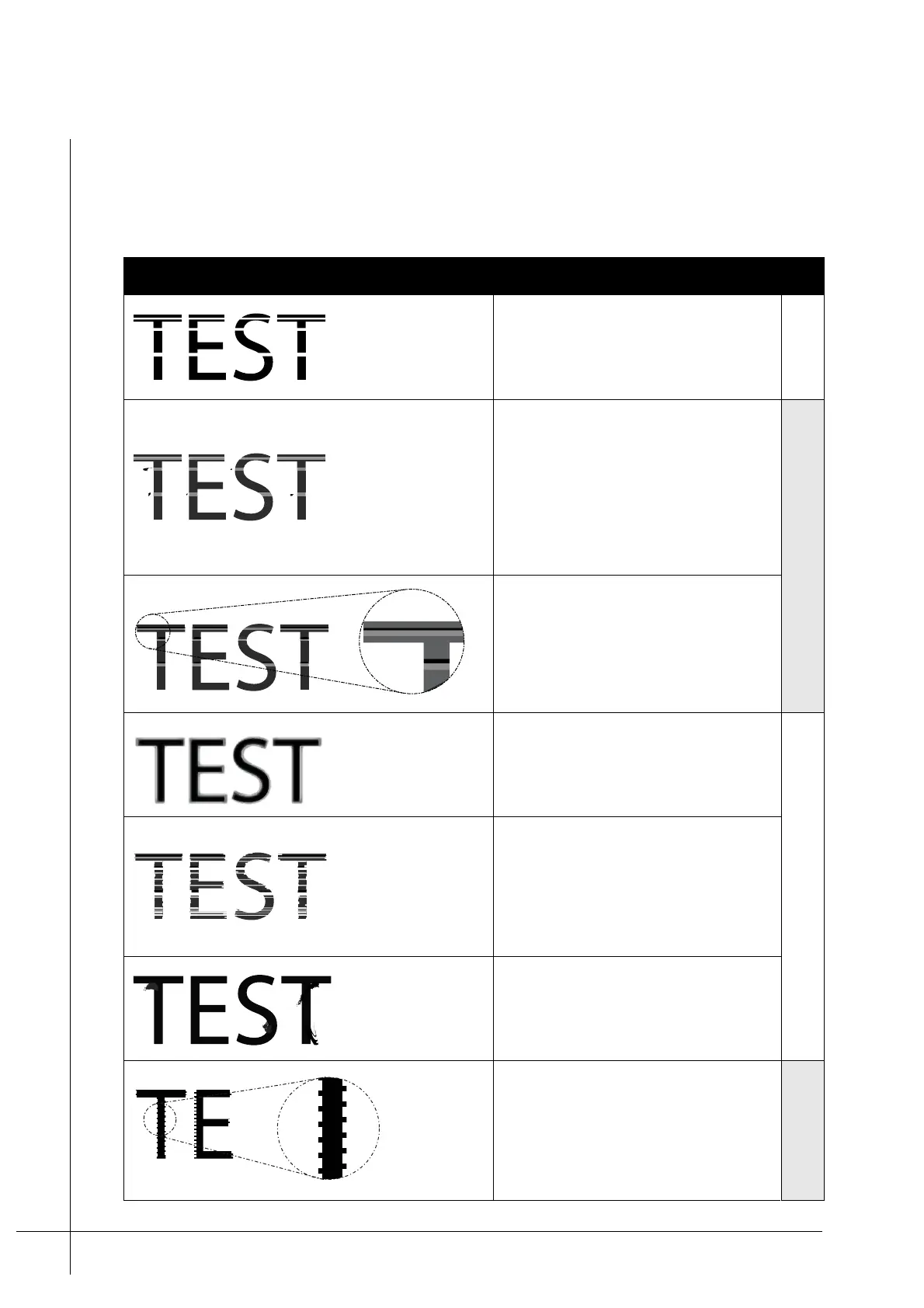

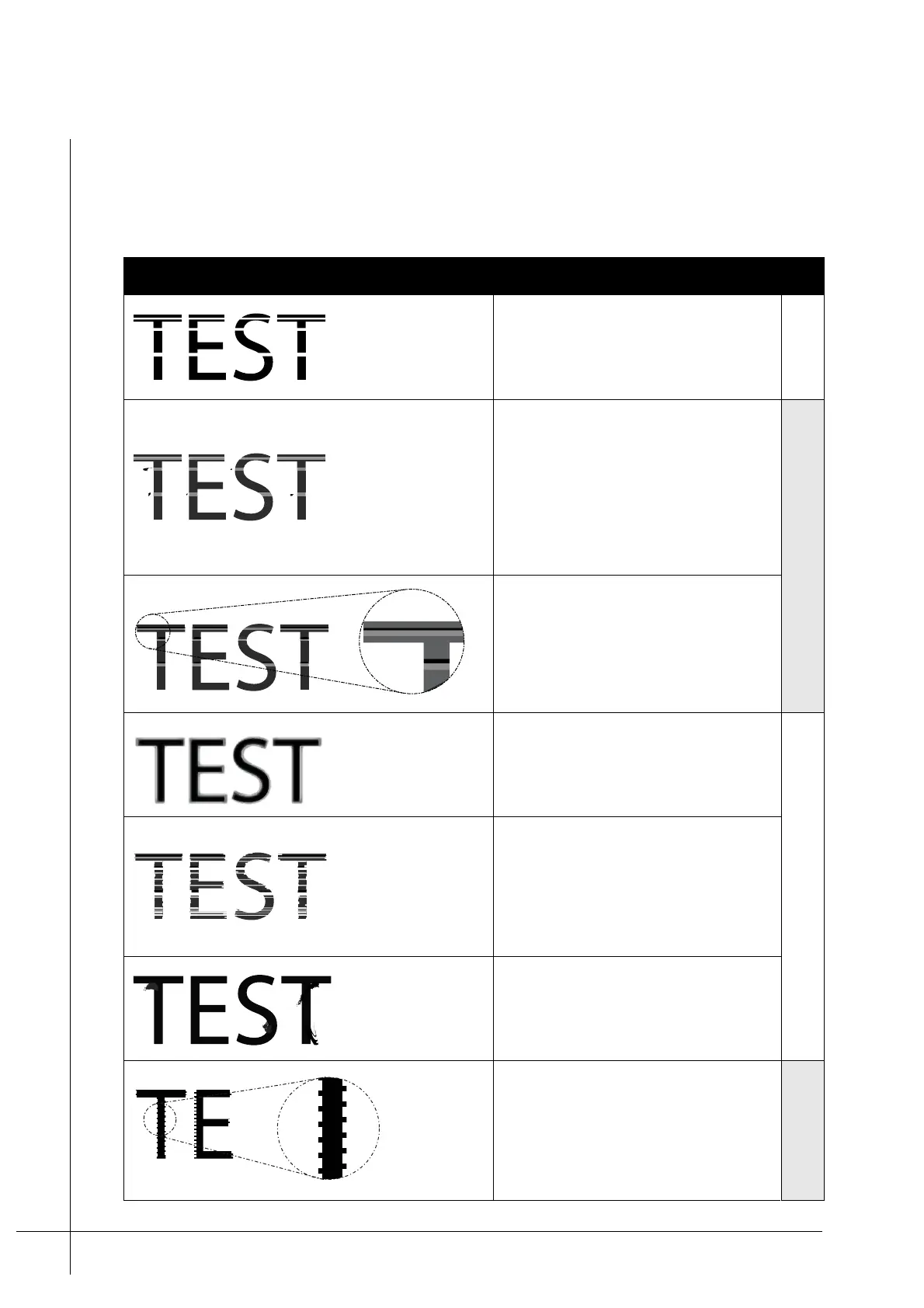

Table 4 - Examples of poor print

Example Possible Cause

Fix

Missing Droplet:

Thin white stripes are produced which are caused by the

loss of a jet(s) or air trapped in the ink system.

Trapped Air

Slow/Short Droplet:

A thin light stripe is produced. Secondary drops

of ink are often seen beside the light stripes.

Dust, dirt, or other small particles have entered

an orifice. This results in ink drops loosing their

velocity.

This is most often caused by the print target

hitting the print head and shredding small

particles which become trapped in the print head.

Clean Nozzles

Mis-aimed Droplet:

A thin light stripe is produced. Adjacent to it is a

darker stripe.

This is usually caused by a partial obstruction of

an orifice.

Over Bold:

The image appears faded around the edge. This

can be the result of: excessive substrate speeds,

throw distance, or type of material being printed

on.

Adjust Throw Distance

Blurred Image:

The image appears blurred. The image has a

combination of the above droplet malfunctions.

This occurs when the distance between the print

head and the print target is too great. Noticeably,

the number of droplet malfunctions are much

greater.

Smudged Image:

The image is smudged. This is caused by the

print target being too close to the print head. The

print target hits the print guides and cause the ink

to smudge.

Scalloped Edges:

The mark has a notched appearance at the

beginning and end of each character/mark.

This can result when the print direction setting of

the controller does not match that of the print

target, or the print target speed does not match

the print head’s printing speed (timing problem).

Encoder/Timing fault

Loading...

Loading...