31

T50/T100 PTM – User Guide – Version 2 Issue 1

Maintenance – Ink-Filter Replacement

Ink-Filter Replacement

The Iink Filter inside the Ink-Reservoir must be replaced every two years or sooner,

dependent upon operating environment. If the PTM is operated in dusty environments it will

require replacement more frequently.

Before starting the following procedure make sure that all warnings and cautions, as listed

under “Maintenance” on page 25 are read and adhered to.

Procedure – Iink Filter Replacement

1. Close the Ink-Vent-Screw.

2. Clean the Nozzle-Protector-Plate with a lint free cloth and then screw it on to the front of

the print head, finger tight. Make sure that it is mounted so the text "Gutter", that is

printed on the plate, is positioned at the bottom of the nozzles. It should be mounted as

shown in Figure 25 on page 30.

3. Make sure that all cables are disconnected and that there is no power supplied to the

PTM.

4. Unscrew and remove the Ink-Bottle from the Ink-Inlet.

5. Make sure that the Ink-Reservoir-Cap is securely screwed in to the Ink-Inlet, so that no

ink is spilt. Then unscrew and remove the five screws that retain the Reservoir-Cover.

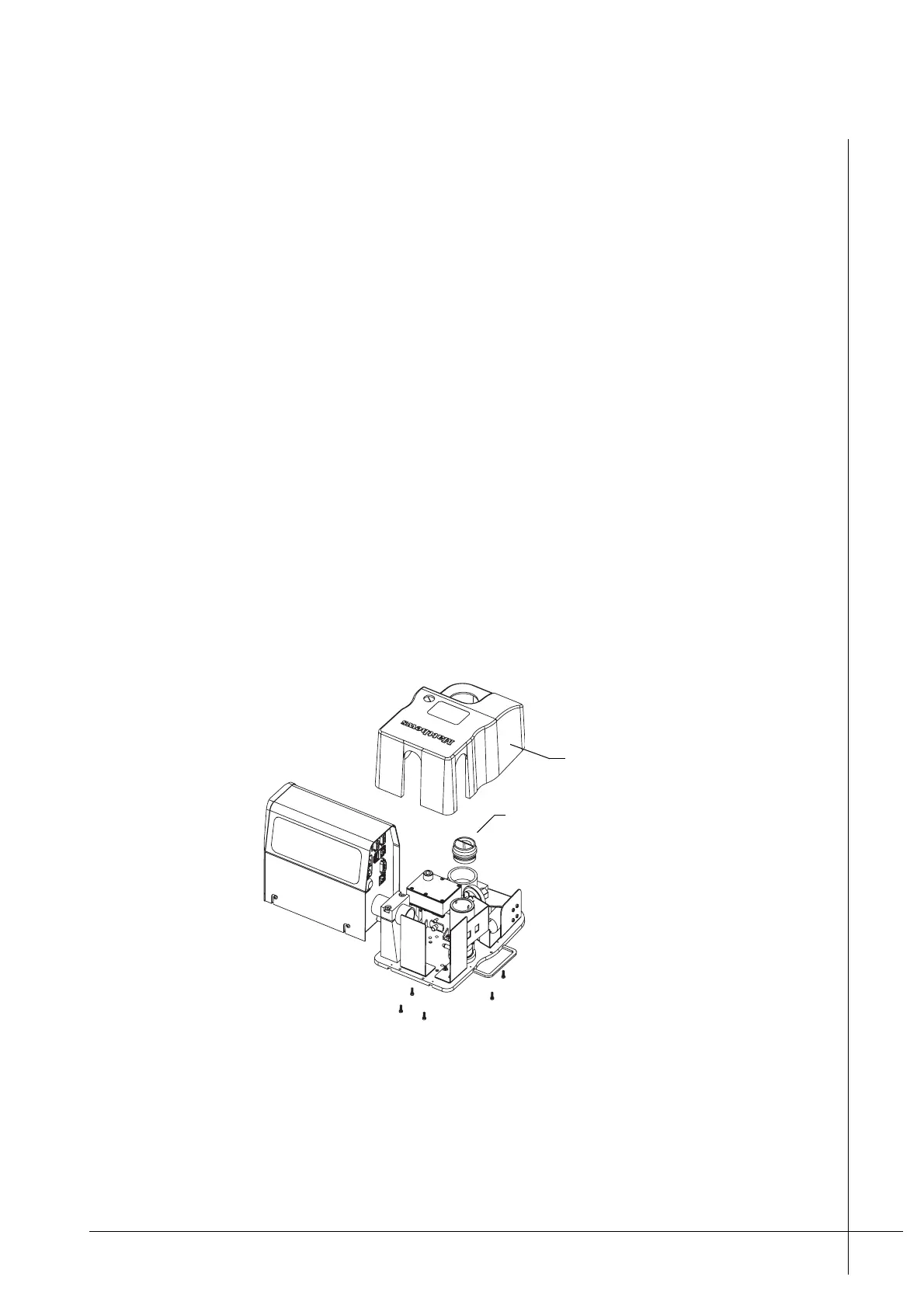

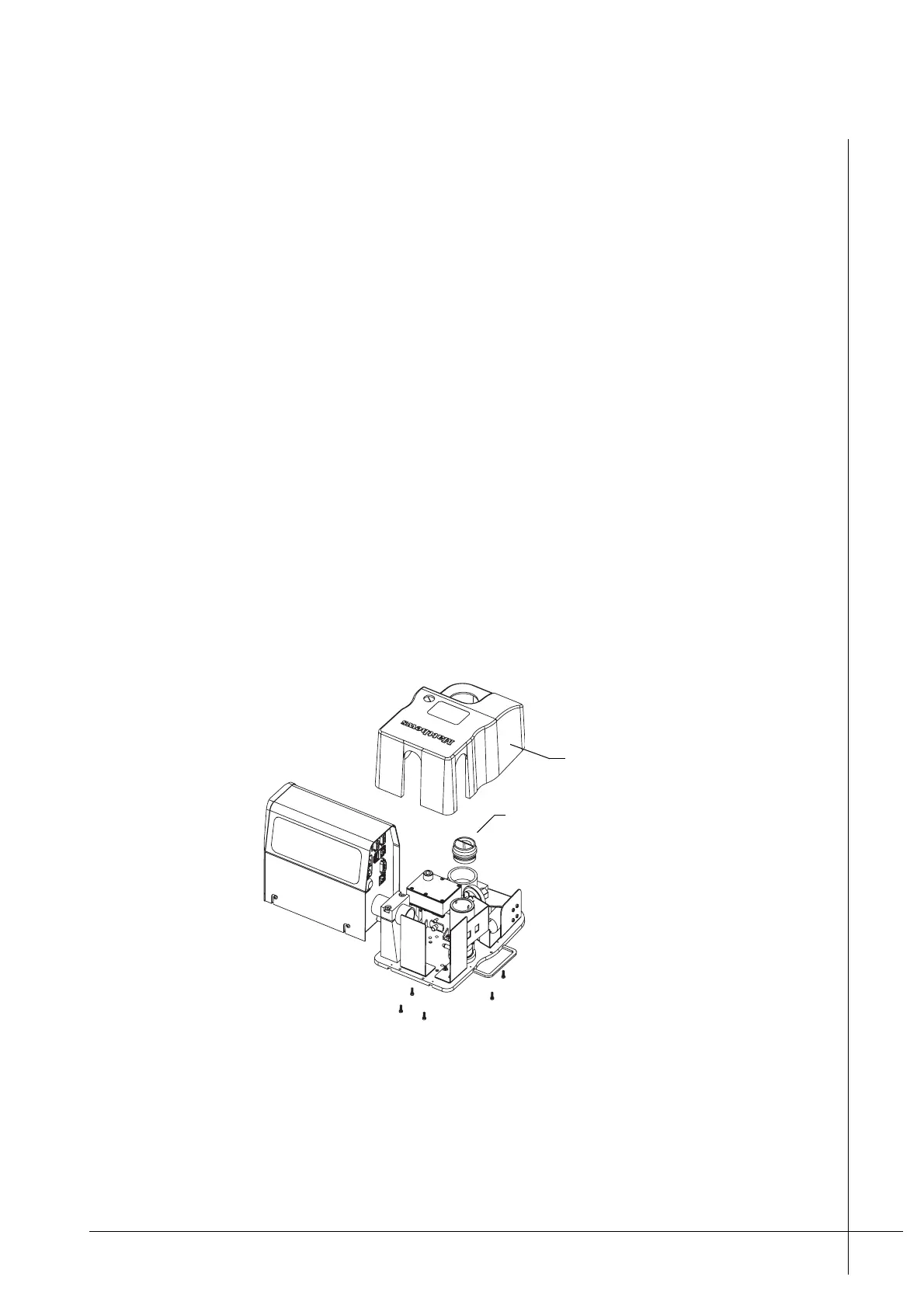

Figure 26 - Removing the Reservoir-Cover

6. Place the PTM so that it is level. Unscrew the Ink-Reservoir-Cap and then remove the

Reservoir-Cover. Screw the Ink-Reservoir-Cap back in to its inlet once the cover is

removed.

Reservoir-Cover

Ink-Reservoir-Cap

Loading...

Loading...