SENSOR PROBE INSTALLATION

Copyright © 2017 McCrometer, Inc. All printed material should not be changed or altered without permission of

McCrometer. Any published technical data and instructions are subject to change without notice. Contact your McCrometer

representative for current technical data and instructions.

www.mccrometer.com

3255 WEST STETSON AVENUE • HEMET, CALIFORNIA 92545 USA Printed In the U.S.A.

TEL: 951-652-6811 • 800-220-2279 • FAX: 951-652-3078 Lit. # 30120-48 Rev. 2.4 / 11-5-18

11

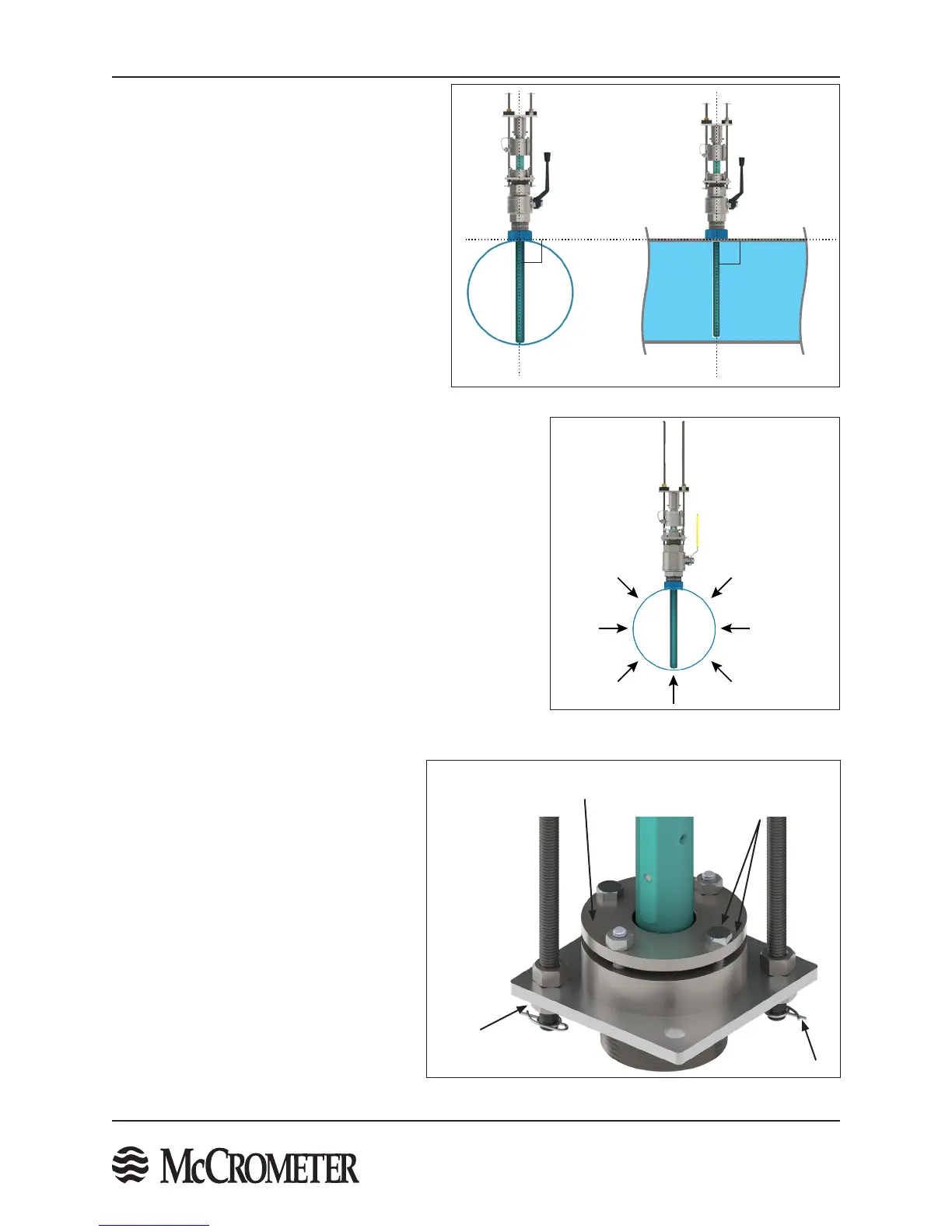

STEP 6: Ensure correct sensor orientation

The FPI should be installed perpendicular to the

pipe as shown in Figure 12 for a vertical installation.

The allowable tolerance for installation is ± 0.5°. A

perpendicular installation is determined by the

coupling that is mounted on the pipe. Prior to

installing the FPI a level ruler should be used to

check the coupling and ensure that it sits level.

The FPI will not be perpendicular to the pipe if the

coupling does not sit level. Do not install the sensor

if the coupling is not mounted perpendicular to

the pipe.

The FPI sensor can be installed at any point around

the pipe diameter, providing the sensor maintains

proper orientation as shown in Figure 13.

90°

90°

Figure 13. Sensor installation points

around pipe diameter

Figure 12. Sensor at 90° relative to pipe

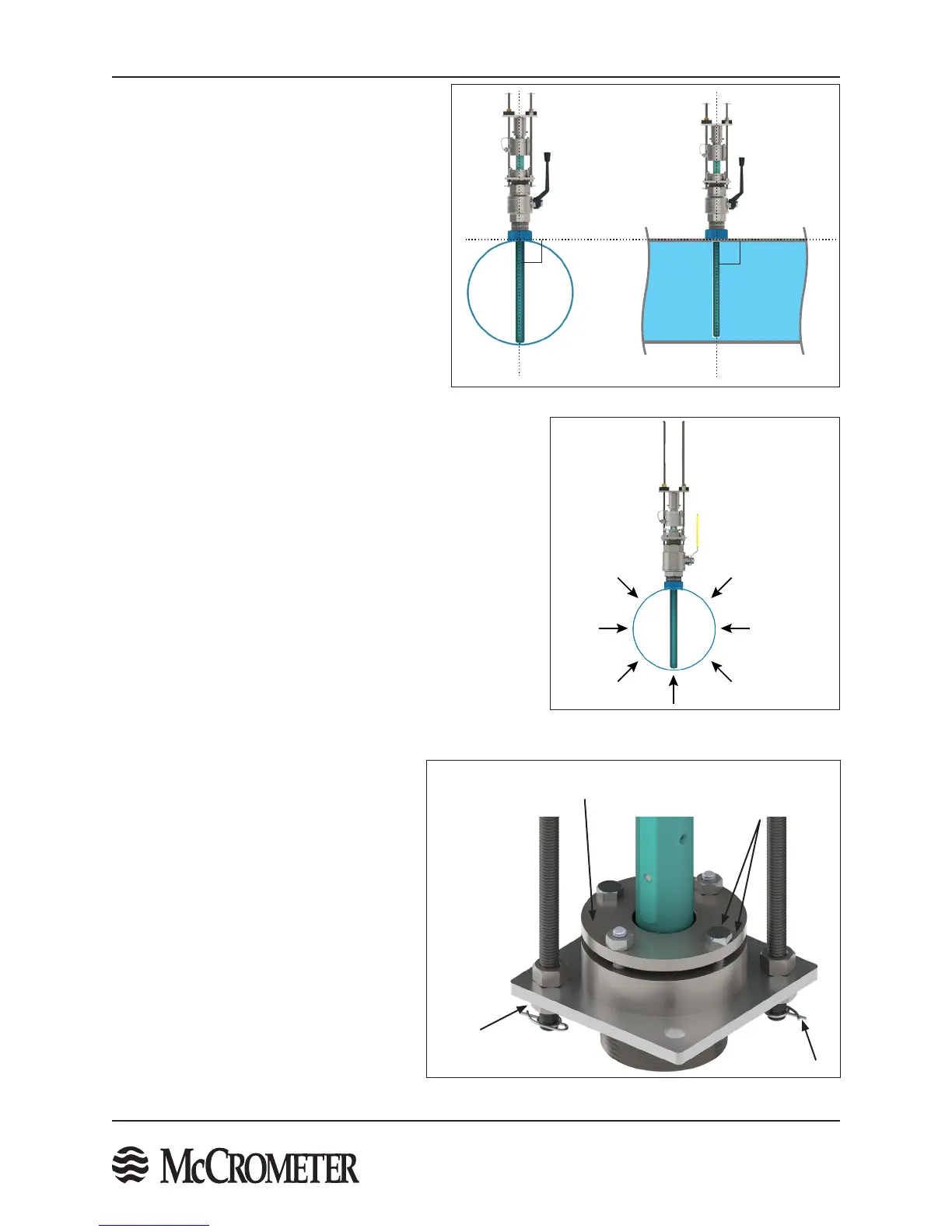

Compression Seal

Lower Retaining

Rod Nut

Locking

Cotter Pin

Compression Seal

Bolt And Nut

Figure 14. Compression seal removal

STEP 7: Optional Compression Seal Disassembly For

Installation Of Large Sensors

The sensor assembly can be installed onto the pipe valve

as a whole unit. On larger pipe size installations this can be

cumbersome or impractical. In such cases the compression seal

assembly can be removed from the sensor for easier installation

onto the pipe valve. Once the compression seal assembly is

installed onto the pipe valve, then the sensor can be re-installed

into the compression seal assembly.

NOTE: if this step is skipped, proceed to STEP 8.

The following steps describe the separation of the sensor, top-

plate and retaining rods from the compression seal assembly.

1. The compression seal has two bolts and two studs with

nuts. Loosen the bolts and nuts on the compression seal

relieving the pressure on the compression seal. DO NOT

REMOVE THE BOLTS OR NUTS.

2. On the compression seal assembly,

remove the locking cotter pins from the

bottom of the two retaining rods under

the 3/8" or 1/2" nuts.

3. Remove the lower 3/8" or 1/2" nuts from

the retaining rods.

4. Slide the sensor out of the compression

seal. The retaining rods will also slide

out of the compression seal assembly.

Carefully set the sensor and attached

hardware to the side.

5. At this point the compression seal

assembly can be installed onto the valve.

FPI sensor may

be inserted at any

point around the

pipe diameter.

Loading...

Loading...