SENSOR REMOVAL

Copyright © 2017 McCrometer, Inc. All printed material should not be changed or altered without permission of

McCrometer. Any published technical data and instructions are subject to change without notice. Contact your McCrometer

representative for current technical data and instructions.

www.mccrometer.com

3255 WEST STETSON AVENUE • HEMET, CALIFORNIA 92545 USA Printed In the U.S.A.

TEL: 951-652-6811 • 800-220-2279 • FAX: 951-652-3078 Lit. # 30120-48 Rev. 2.4 / 11-5-18

19

Follow the steps below to safely remove the sensor:

1. Visually inspect the pipe and entire assembly

for damage or corrosion paying close attention

to any nipples and welded couplings. If there is

any doubt as to the condition of any element of

the pipe or meter, depressurize the line before

attempting to remove the meter.

2. Reduce line velocity to 5 ft/s or less to prevent

sensor vibration, or depressurize the line.

3. Thread a long retaining rod through the

captive nut until the rod nears the compression

assembly. Ensure that the bottom of the rod has

the hole for the locking cotter pin.

4. Thread a 3/8" nut onto the bottom of the long

retaining rod about an inch up from the bottom

of the rod.

5. Continue rotating the long retaining rod until

the bottom of the rod passes through the holes

on the bottom plate.

6. Thread another 3/8" or 1/2" nut onto the bottom of the long retaining rod until it is ush with the bottom

plate. Tighten the nuts above and below the bottom plate securely locking the long retaining rod in place.

Attach the locking cotter pin into the hole through the bottom of the long retaining rod.

7. Repeat the process for the second long retaining rod.

8. Once both of the long retaining rods are securely in place, completely remove the short retaining rods.

9. Loosen the compression seal bolts until the seal just begins to leak. This will relieve the pressure on the

compression seal allowing the sensor to be removed. Draping a towel around the compression seal can

reduce any spraying water. NOTE: The compression seal may prevent immediate leakage on sensors installed

for a long period of time until the sensor begins to rise.

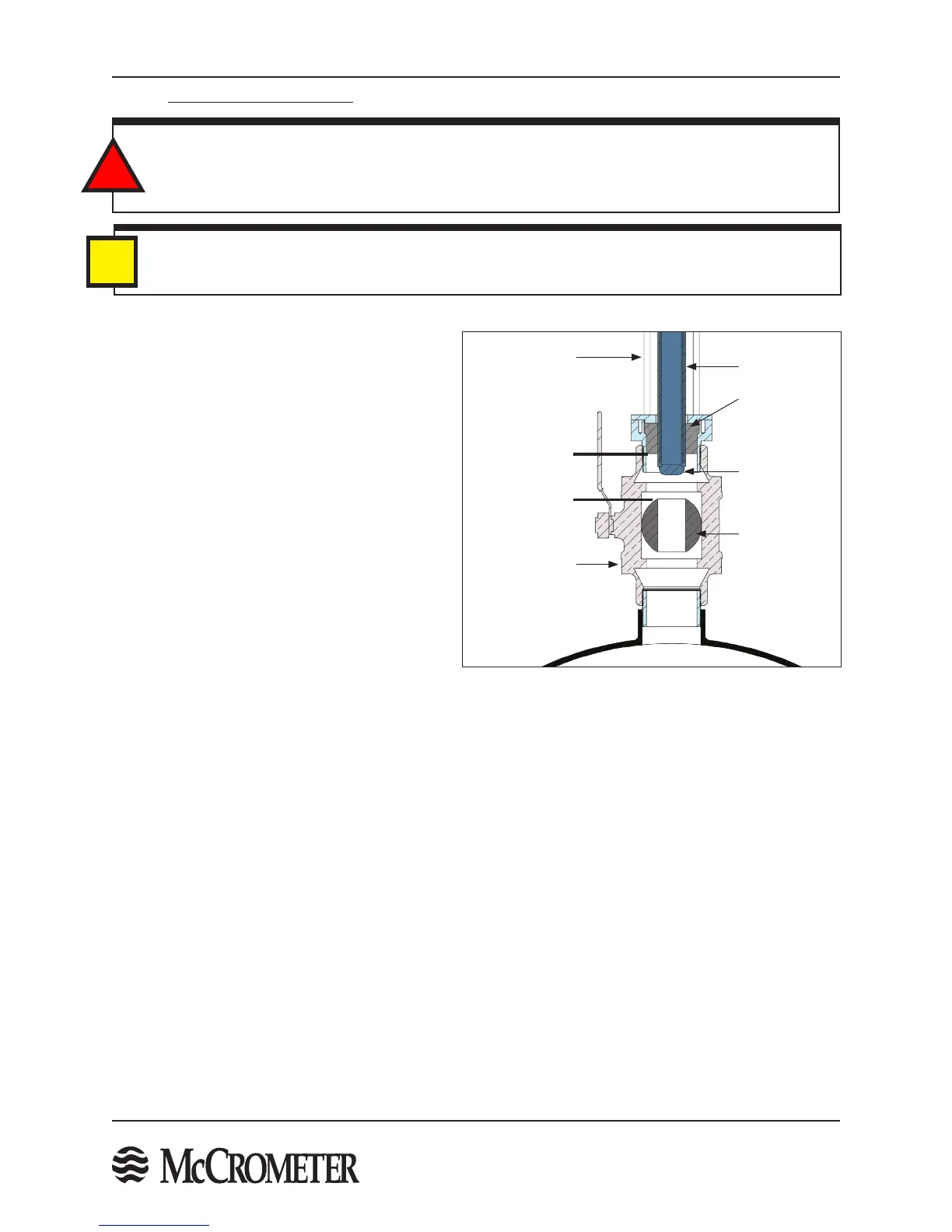

10. Rotate the captive nuts on the top plate simultaneously. The sensor insertion tool is recommended. See

Installation, STEP 10. This will cause the sensor to rise out of the pipe. If the line is under pressure do not

remove the sensor from the compression seal completely. Only raise the sensor until it is clear of the valve, but

still below the compression seal. See Figure 24. Once the sensor has cleared the valve mechanism, the valve

can then be closed. Do not attempt to force the valve closed while the sensor is still passing through the valve

as permanent damage to the sensor can occur.

11. Once the valve is closed, the entire sensor can be removed from the valve.

3.0 SENSOR REMOVAL

WARNING!

The pipe may be under pressure. Serious injury or death may result if proper procedures are not followed.

Do not attempt to remove the short retaining rods without the long retaining rods properly installed. Do

not attempt to remove the sensor with only the short retaining rods.

!

IMPORTANT

Use the long retaining rods provided with the meter for removal. If the rods used for removal are shorter

than those provided by the factory, the sensor cannot be removed without depressurizing the line.

i

Figure 24. Cross-Section Of Meter Showing

Sensor Removal

Compression

Seal

Sensor

Bottom Of

Sensor

Valve Closure

Mechanism

Space Between

Bottom Of

Seal And Valve

Mechanism

Pipe Valve

Retaining

Rods

Loading...

Loading...