uNPACKING AND VERIFYING COMPONENTS

Copyright © 2017 McCrometer, Inc. All printed material should not be changed or altered without permission of

McCrometer. Any published technical data and instructions are subject to change without notice. Contact your McCrometer

representative for current technical data and instructions.

www.mccrometer.com

3255 WEST STETSON AVENUE • HEMET, CALIFORNIA 92545 USA Printed In the U.S.A.

TEL: 951-652-6811 • 800-220-2279 • FAX: 951-652-3078 Lit. # 30120-48 Rev. 2.4 / 11-5-18

2

1.0 UNPACKING AND VERIFYING COMPONENTS

The FPI Mag® (Full Prole Insertion) ow meter provides accurate ow measurement for full-pipe clean water

applications. The electromagnetic sensor automatically senses and corrects for shifting velocity in the pipe by

constantly obtaining an area weighted mean velocity. Model 394L is a forward and reverse ow measurement

sensor, and the 395L is a forward only ow measurement sensor. The instrument has all of the features needed to

suit a wide variety of applications.

The ow meter is comprised of the innovative FPI Mag sensor (item #1 below) and a converter (item #4 below). For

converter installation instructions, see the manual provided for the converter purchased with your system.

The sensor is easily installed without service interruption, and requires no site calibration. Installation without

service interruption can be done only when adhering to safe hot-tapping procedures, or in locations already tted

with an appropriate full port ball valve, corporation stop or gate valve.

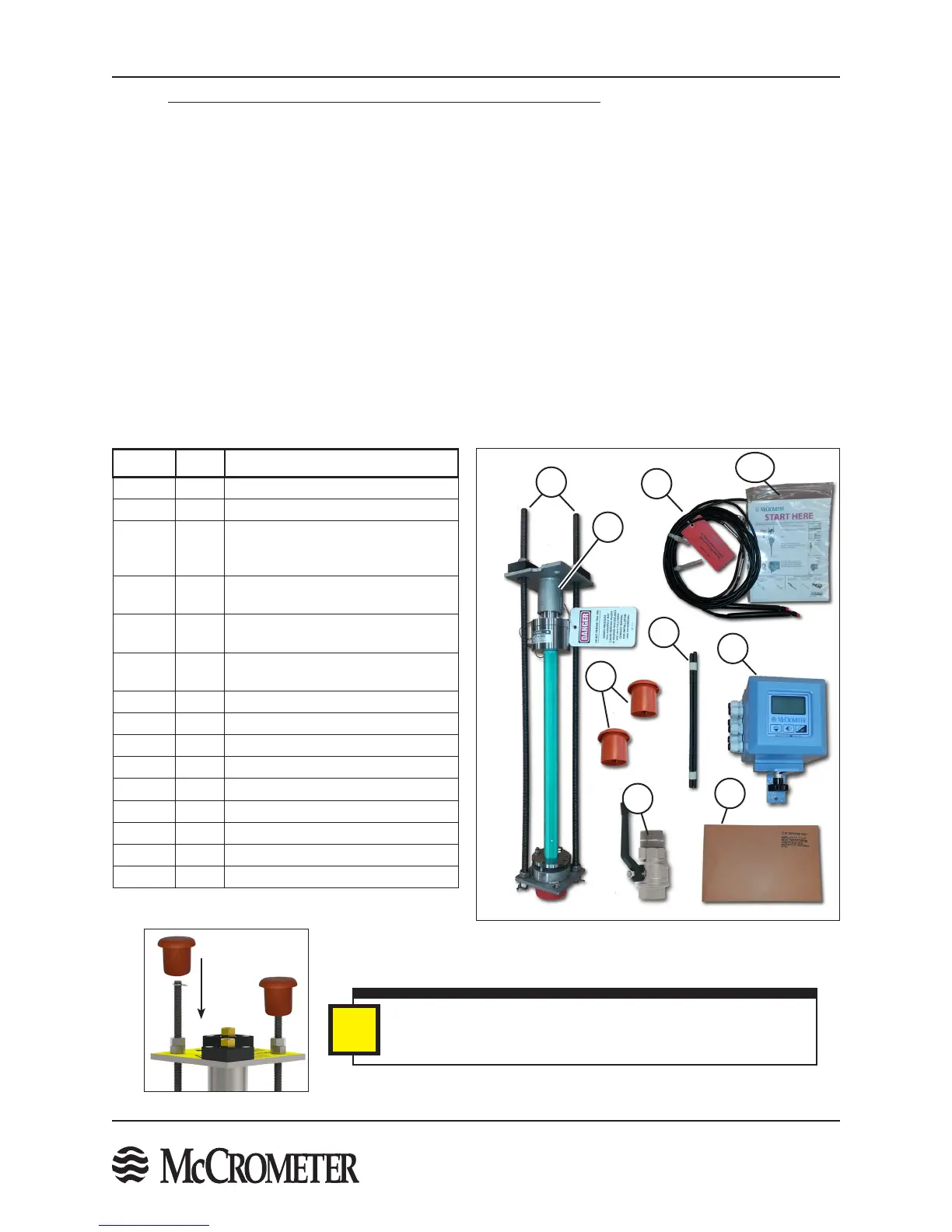

1.1 Unpack the Shipping Box and Verify Contents

Upon receiving the meter, unpack the contents of the shipping box and verify that the items in Figure 1 are

included.

NOTE: If any of the above-listed items are not present, contact the factory before continuing with installation.

Item # Qty. Description

1 2 Long threaded insertion rods

2 1 FPI Mag Sensor

3 2

Cables with Quick-Connects

(Compression cable glands are

available as an option)

4 1

FPI Mag Installation Operation and

Maintenance Manual

5 1

Converter Installation Operation and

maintenance Manual

6 2

9/16" or 3/4" reversible ratchet

wrench

7 1 Pipe thread sealant

8 8 Hex nut (3/8" or 1/2")

9 4 Locking cotter pin

10 1 Power cord (8', 115 VAC)

11 2 Protective cap for retaining rods

12 2 Short threaded retaining rods

13 1 Converter (M Series or L Series)

14 1 Stainless Steel ball valve & SS nipple

15 1 Calibration Certicate

Figure 1. Shipping Box Contents

3

14

1

2

12

15

11

13

4-10

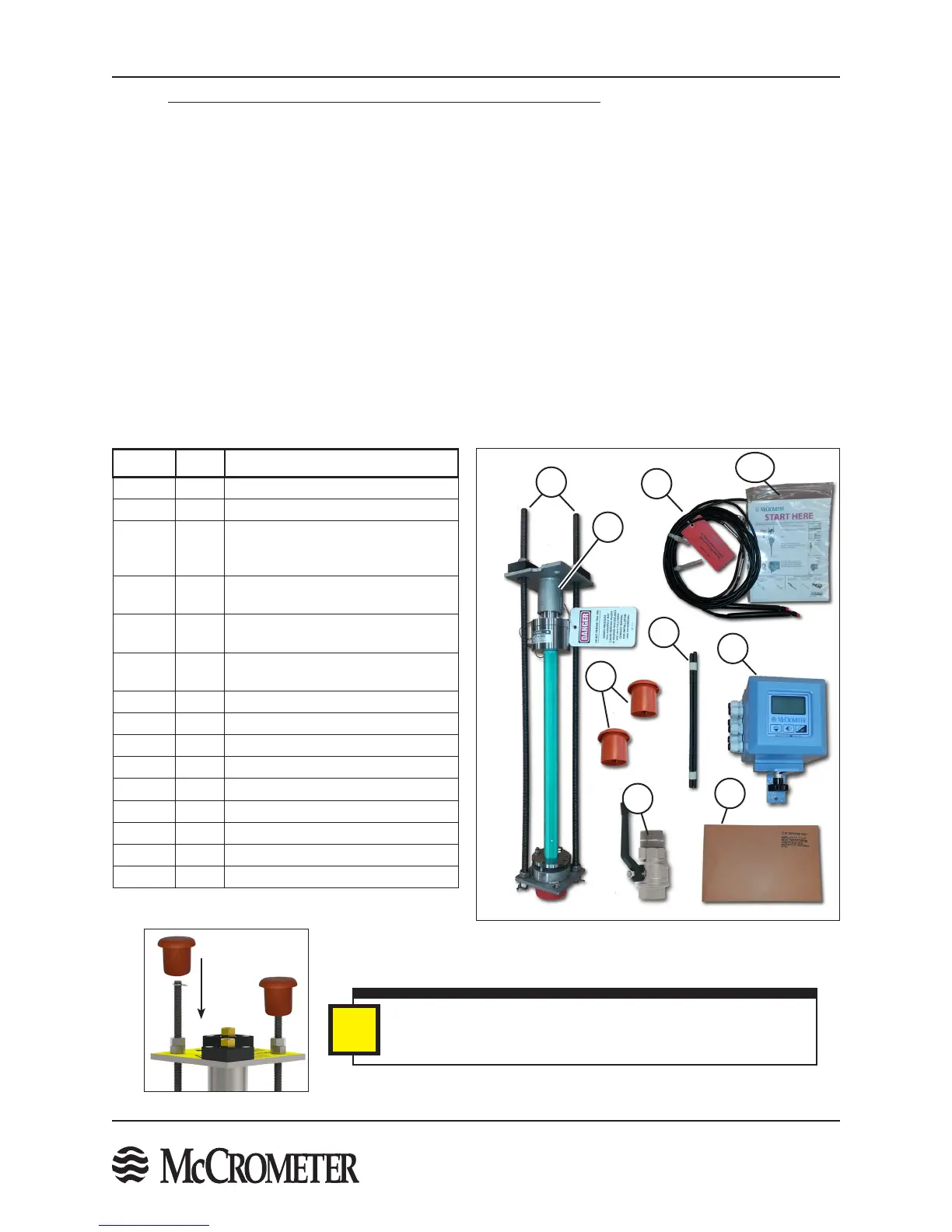

Note: Do not discard the protective end caps (item 11). They will

be needed when the sensor is fully installed. See STEP 13.

i

Loading...

Loading...