SENSOR PROBE INSTALLATION

Copyright © 2017 McCrometer, Inc. All printed material should not be changed or altered without permission of

McCrometer. Any published technical data and instructions are subject to change without notice. Contact your McCrometer

representative for current technical data and instructions.

www.mccrometer.com

3255 WEST STETSON AVENUE • HEMET, CALIFORNIA 92545 USA Printed In the U.S.A.

TEL: 951-652-6811 • 800-220-2279 • FAX: 951-652-3078 Lit. # 30120-48 Rev. 2.4 / 11-5-18

7

STEP 2: Detach The Cable Quick Connects

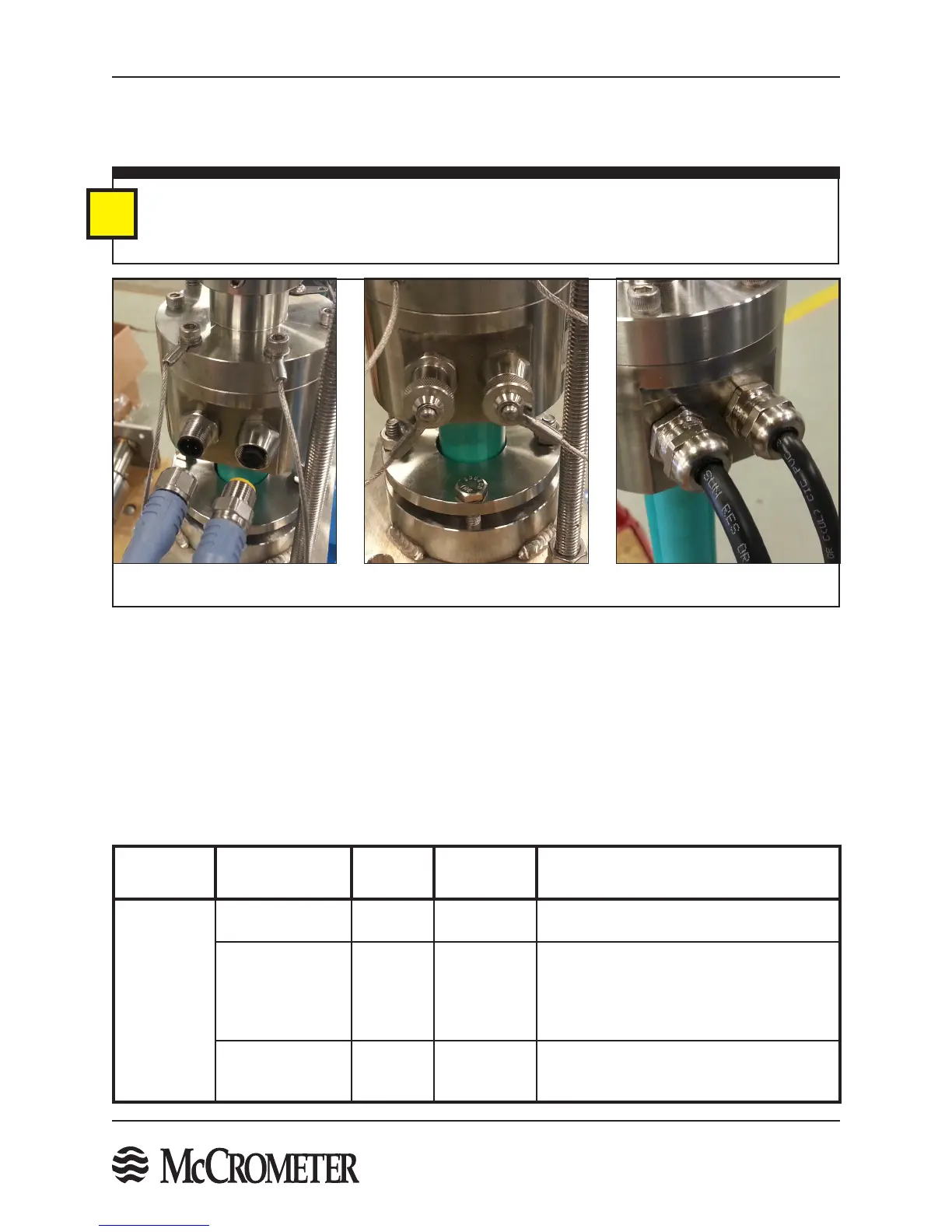

The sensor cable is tted with an IP68 rated Quick Connect tting at the sensor connection. For ease of installation,

remove the cable from the sensor and set aside. Compression gland seals are available as an option instead of the

Quick Connect cable ttings.

IMPORTANT: When the Quick-Connect cable connection is not attached to the sensor, ensure that

the threaded caps are attached to the sensor connection and the cable connection to keep the wire

connectors free of dirt and corrosion. When the cable is connected to the sensor, connect the end caps

together to keep their interior free from dirt and corrosion.

i

Quick Connect Cables Fittings With End Caps

Optional Compression Gland

Cable Fittings

STEP 3: Verify Sensor Installation Location - Upstream And Downstream Straight-Pipe Run Recommendations

Figure 6. Sensor Cable Fittings

Flow disturbers such as partially open valves cause ow disturbances that can adversely aect ow meter accuracy.

The table below provides suggestions for the placement of the FPI Mag sensor upstream and downstream

of common ow disturbers to meet specication accuracy. The upstream and downstream straight-pipe

recommendations are conservative, based on research completed in the McCrometer NIST traceable calibration

facility. In many cases, the installation distances suggested below can be shortened depending on ow conditions

and piping layout.

Upstream and Downstream Straight Pipe Run Recommendations

Flow

Disturbance

Condition Upstream Downstream Notes

Buttery

Valve

100% Open 2D 1D

Meter should be installed perpendicular to

the axis of rotation of the valve - See Figure 8

Non-Actuated

Control Valve

5D 1D

For Buttery Valves that remain in a constant

position between 50% to 100% open

during operation. Meter should be installed

perpendicular to the axis of rotation of the

valve - See Figure 8

Actuating Control

Valve

20D; See

Note and

Figure 7

2D

Recommended to install the sensor 2D

upstream of the Automated Control Valves

Loading...

Loading...