Page 30 of 64

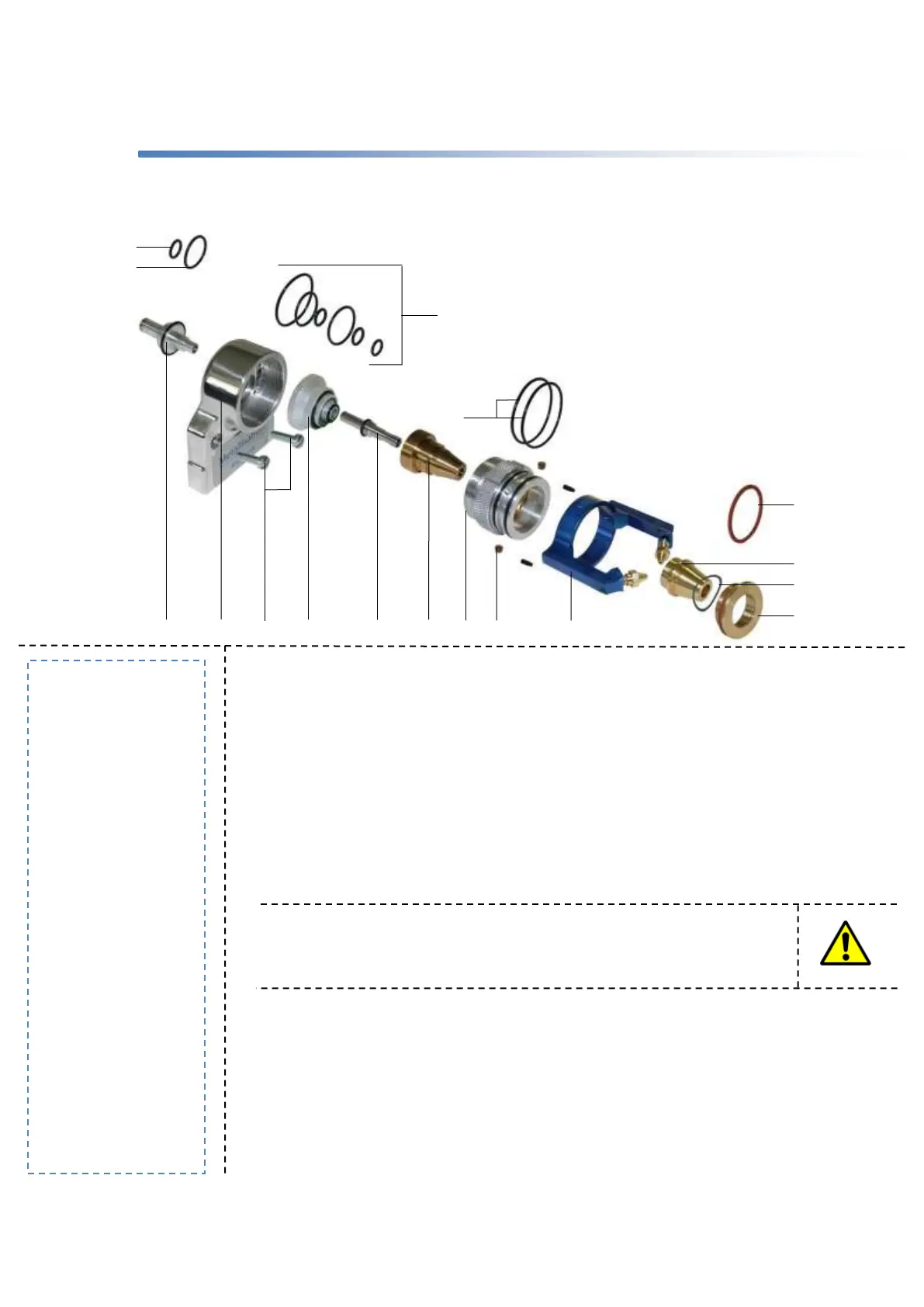

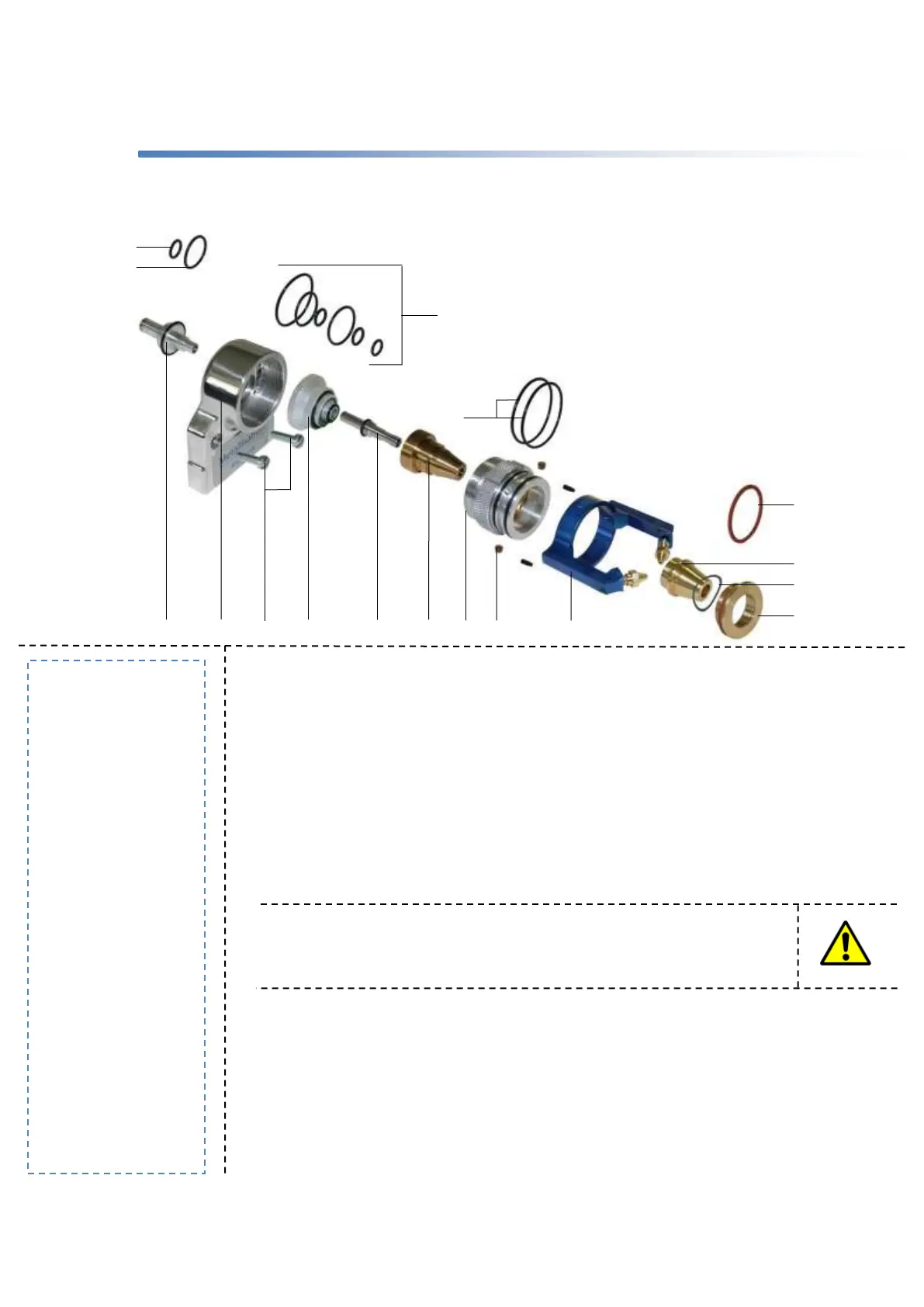

4.4 The Nozzle Assembly

4.4.1 Removal & Dismantling

Referring to DIAG 1, use the following procedure to dismantle the

Nozzle Assembly, when necessary:

If fitted, pull off the Spreader Ring (A) and discard any damaged ‘O’

Rings (M) or cork seals (N).

Unscrew the Lock Ring (B) at the front of the nozzle to release the Air

Nipple (C) and Flexible Spacing Washer (D).

Unscrew the Spreader Air Cover (E) from the Gas Head (F) to release

the Nozzle Shell (G) and Mixing Block (H).

NB: If any difficulty is experienced in removing the Lock Ring (B) or the Air

Cover (E), DO NOT force the thread. Instead, apply penetrating oil and

ease the parts in and out until they can be removed easily.

Carefully pull the Nozzle Shell (G) from the Mixing Block (H), and

remove and replace ‘O’ Rings.

Remove the Screwed Insert (O) and replace ‘O’ ring as required.

Remove carefully, If using pliers, be careful not to distort.

WHEN & WHY?

The Nozzle Assembly

should only be dismantled

when it is absolutely

necessary.

For example:

If it is dirty/worn.

If it is damaged.

When needing to

change the Wire

Diameter.

Loading...

Loading...