Page 42 of 64

4.8 Feed Roller Tension

4.8.1 Checking Feed Roller Tension

When the pistol is fully assembled, connect an airline to the drive motor.

Pass a length of the wire to be sprayed through the pistol and close the drive rollers.

Start the drive motor and adjust the speed to give a medium feed rate.

Holding the pistol in one hand, take a firm grip of the wire in the other and attempt to hold

back the wire and stop the wire feed.

If the feed rollers start to slip on the wire and allow the feed to be slowed or stopped, the

feed roller tension is insufficient and should be adjusted.

NOTE: The correct feed roller tension is the minimum which prevents roller slip in this test.

DO NOT apply excessive tension as this may damage the wire surface and increase wear on

the pistol drive and nozzle components.

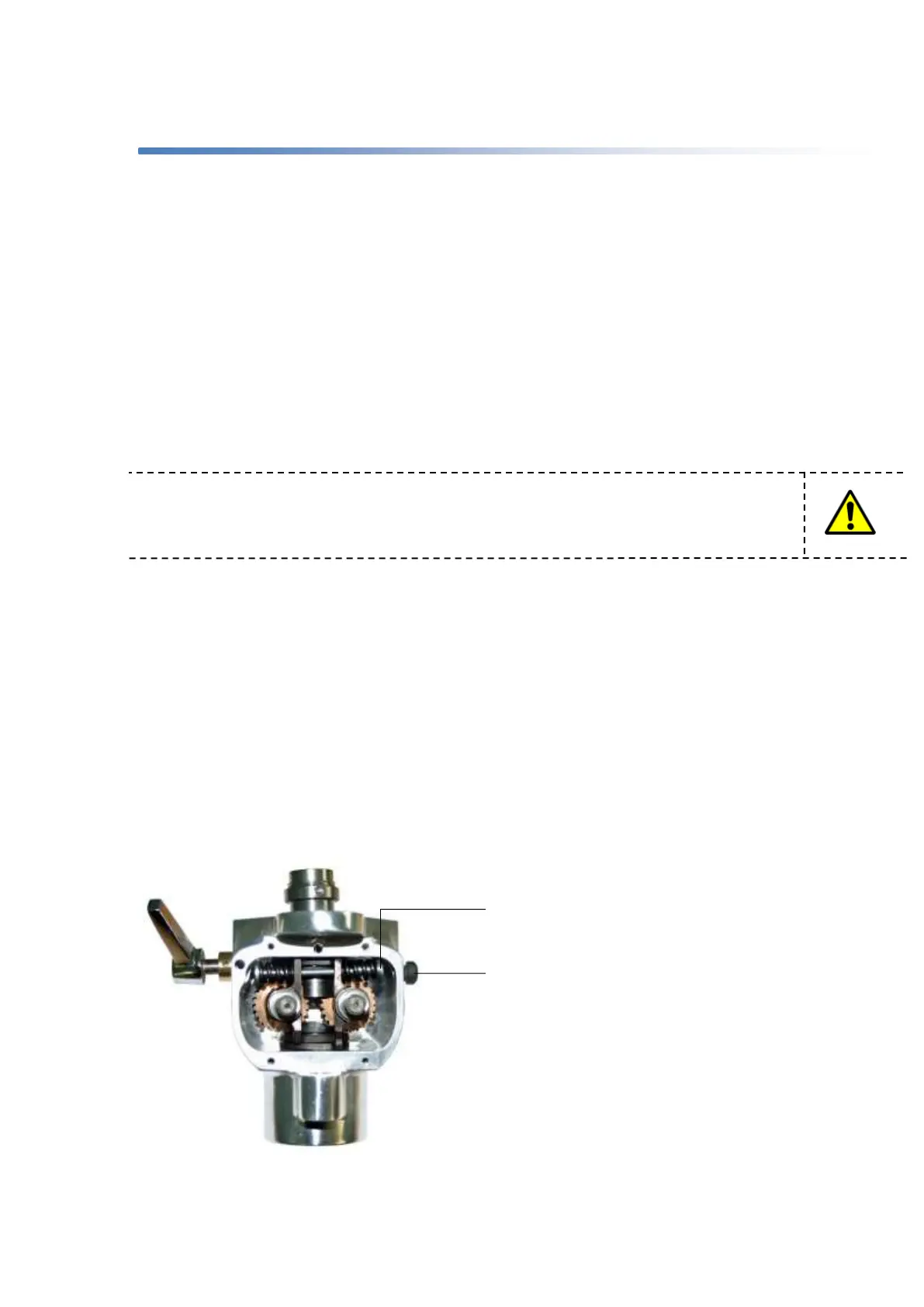

4.8.2 Adjusting Feed Roller Tension

Remove the cover plug on the top right hand side of the pistol.

Using a small flat bladed screwdriver, locate the Slotted Head Screw within the body.

Turn this screw clockwise to increase the feed roller tension or anti-clockwise to reduce it.

Re-check the tension as above and, if satisfactory, replace the cover plug. DIAG 18

(below) indicates the positions of these parts.

Loading...

Loading...