Page 46 of 64

5.1.2 Flowmeter Troubleshooting:

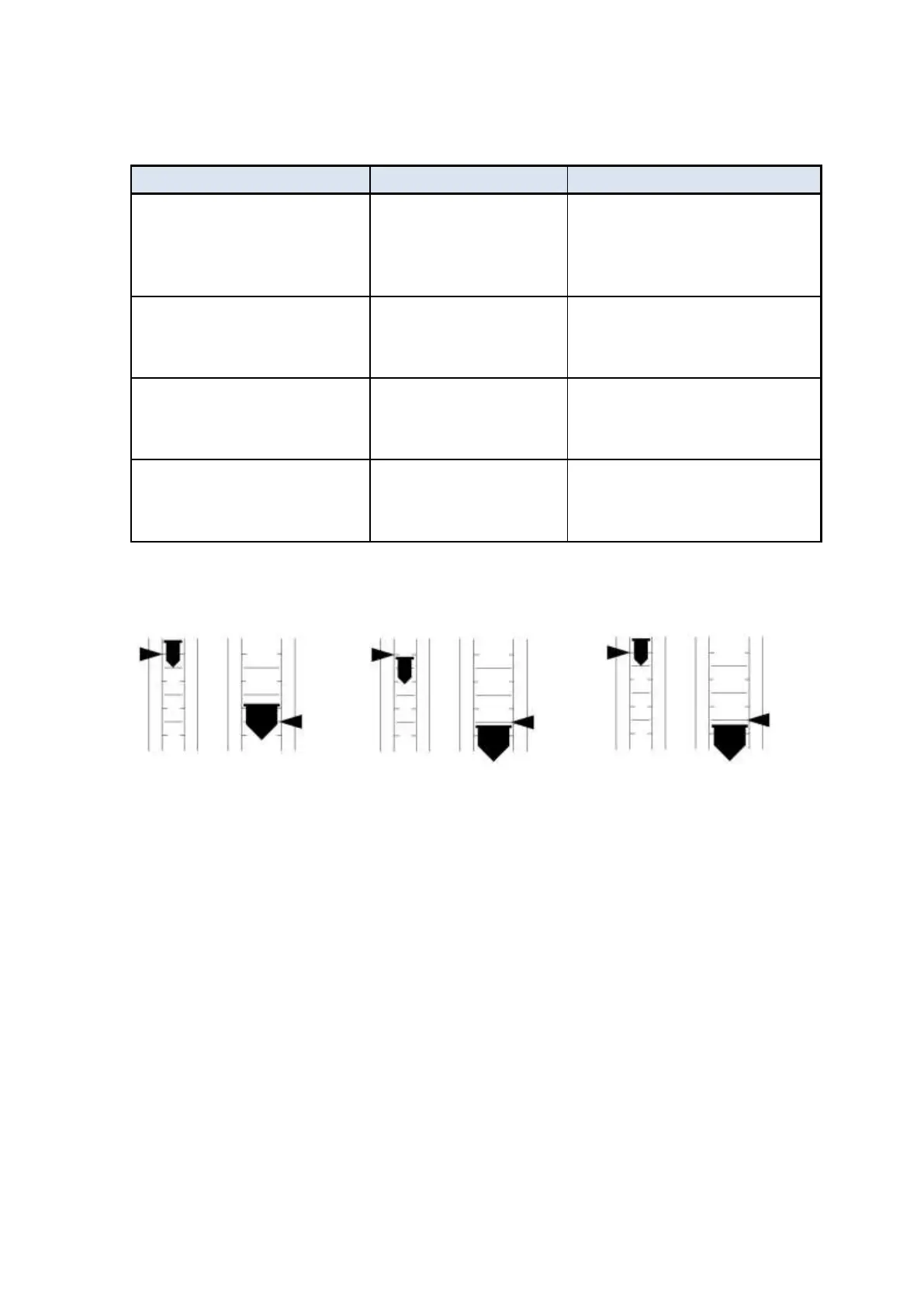

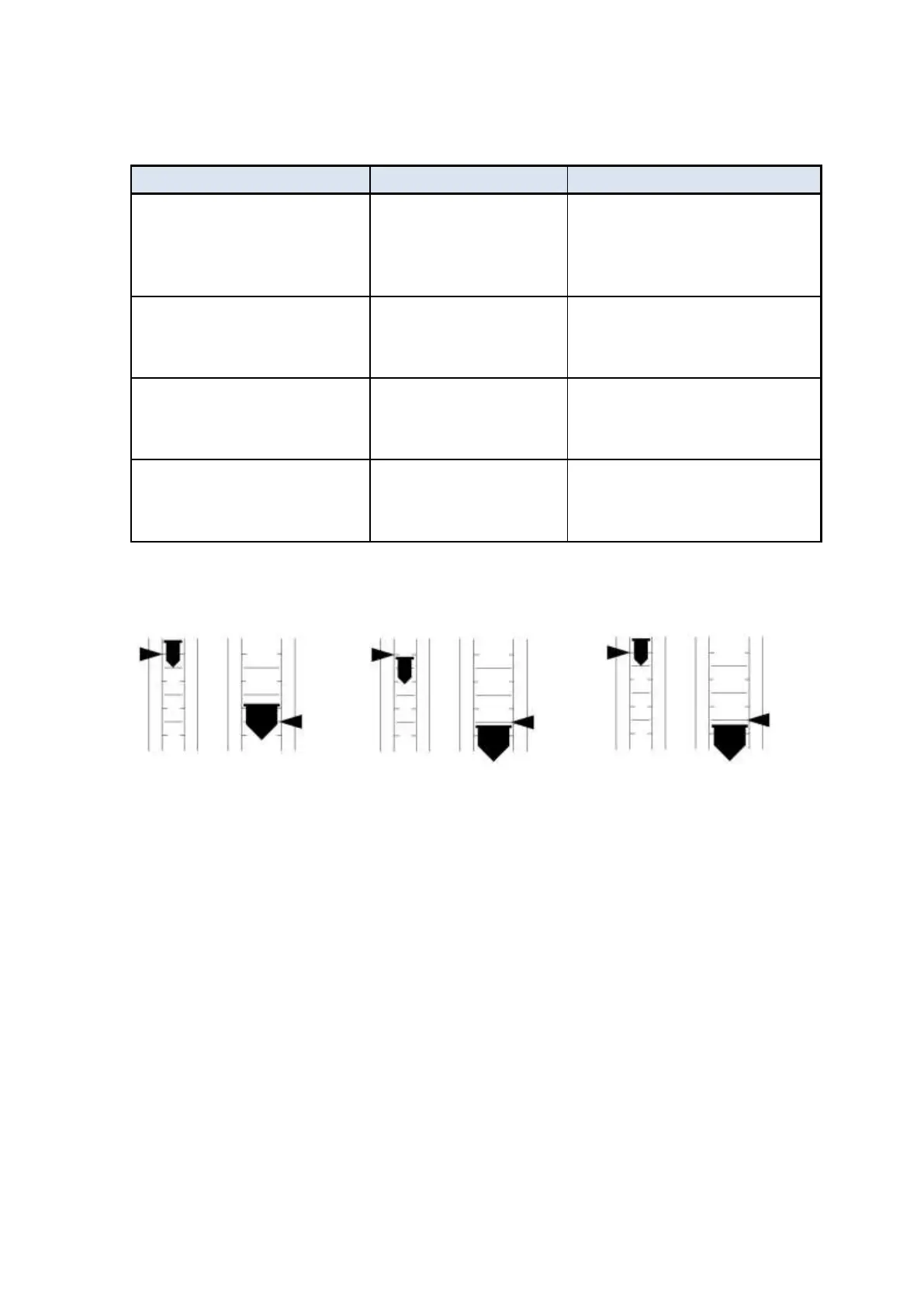

Example Readings:

Use DIAG 19 (above) and the following information to determine the usability of the

pistol under specific flowmeter conditions:

Note (a)

This type of reading, with both floats equally high and pressures correct, can be due to:

Oversize nozzle holes or oversized air nipple or too little air pressure.

Mixing Block holes too large (This mainly with Fine Spray Nozzle Systems).

Pressure Gauges reading too low.

In all cases, the pistol will be quite usable if the flowmeter readings are within 15% of

recommended readings. Spray throughput may be increased.

OXYGEN FLOAT - NORMAL

GAS FLOAT - LOW

Restriction in Nozzle

Gas hole in Mixing Block

restricted

Clean Nozzle with special

Metallisation cleaners

Clear or replace Mixing Block

OXYGEN FLOAT - HIGH

GAS FLOAT - LOW

Middle ‘O’ Ring at rear of

Mixing Block missing /

damaged

OXYGEN FLOAT - LOW

GAS FLOAT - LOW

Outer ‘O’ Ring at rear of

Mixing Block missing /

damaged

OYGEN FLOAT - LOW

GAS FLOAT - HIGH

Restriction in Mixing Block

oxygen holes missing /

damaged

Clear or replace Mixing Block

Loading...

Loading...