Page 45 of 64

Troubleshooting continued:

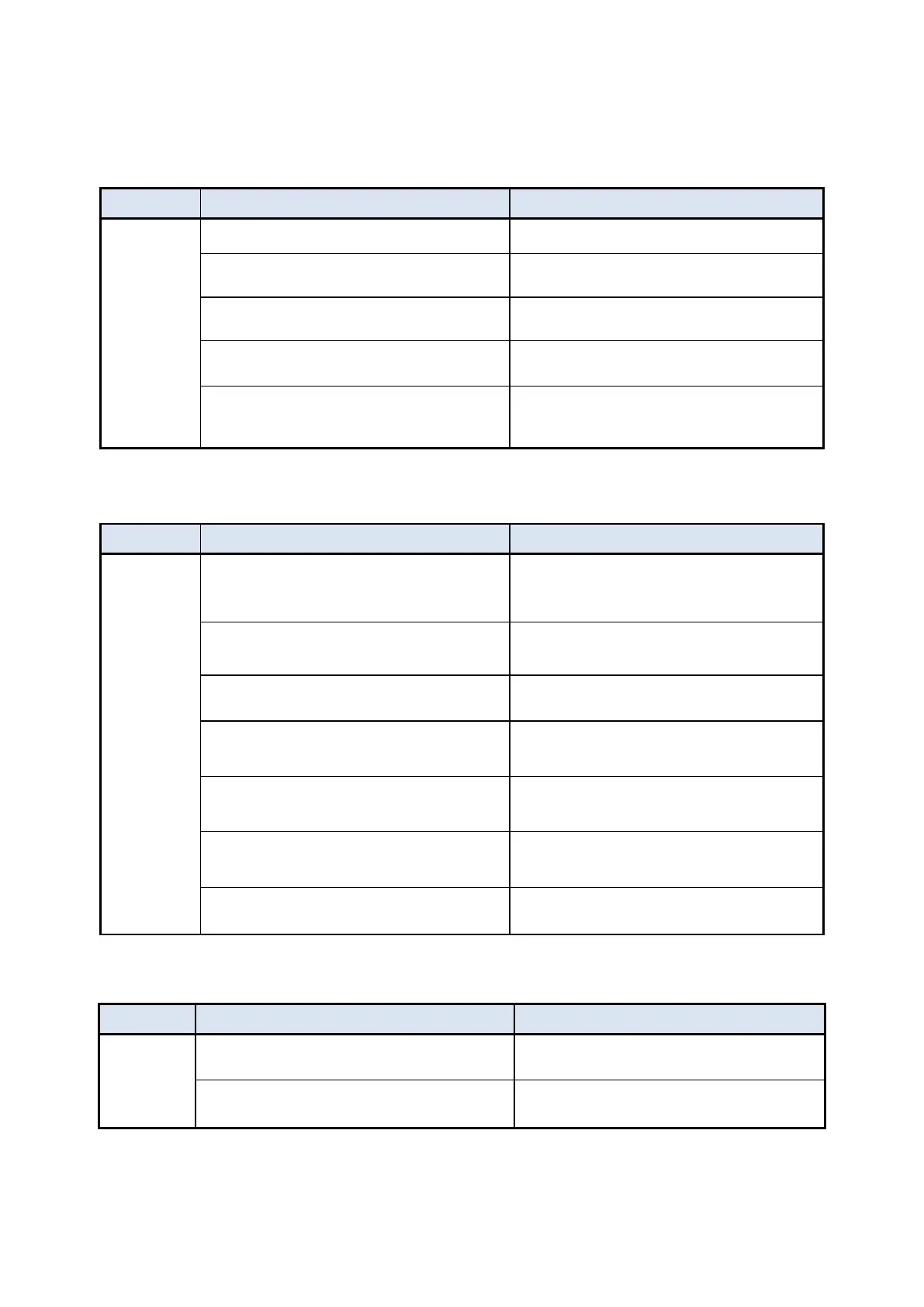

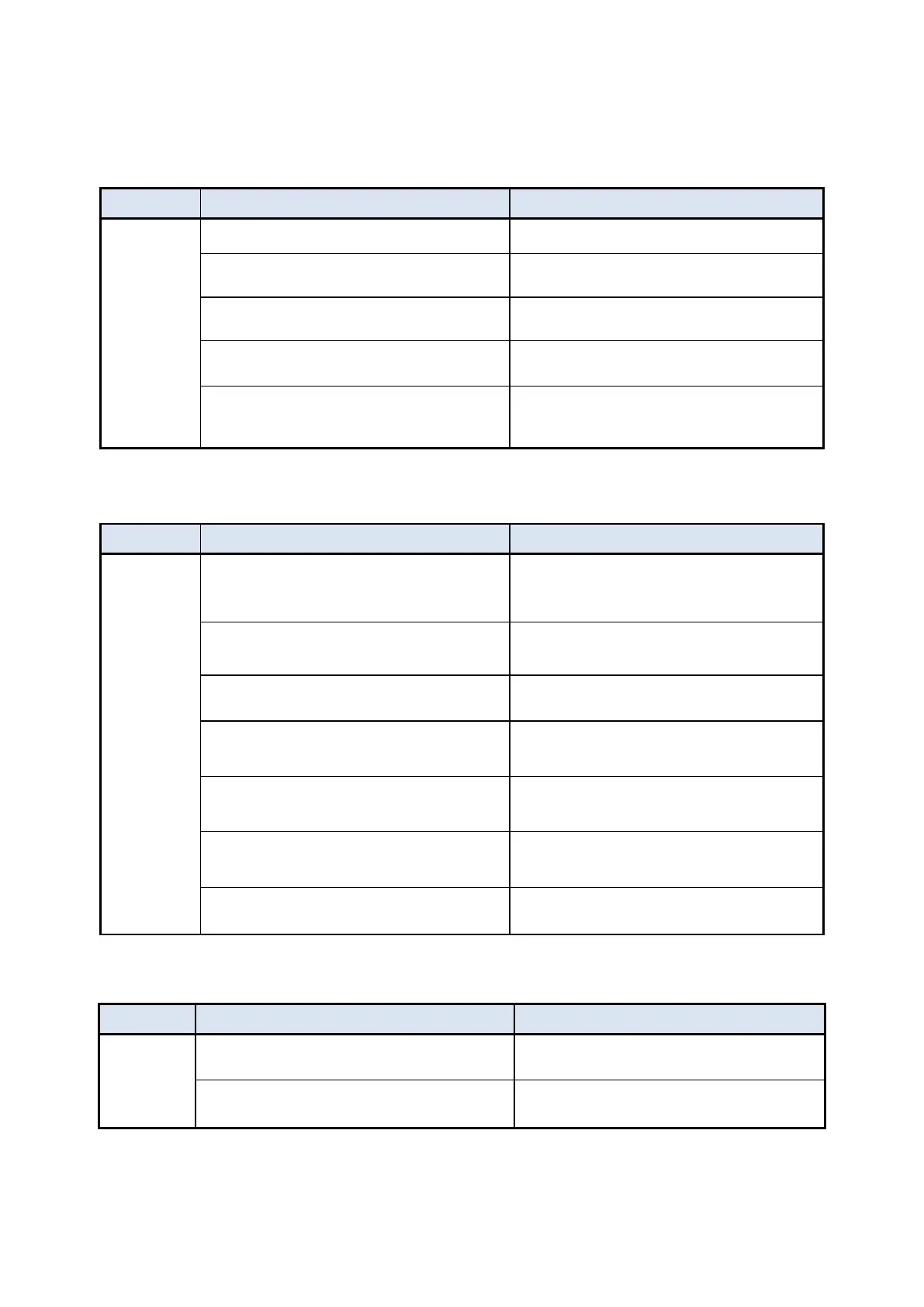

The coating

is too coarse

Insufficient air pressure

Check supply and re-adjust regulator

Air Nipple dirty or damaged

Clean or replace Air Nipple

Air nipple jammed in lighting position

Remove and re-fit Air Nipple, checking that it is

free to move on the Nozzle

Nozzle assembly parts dirty or damaged

Remove and clean, or replace Nozzle

Assembly parts as required

Wire Sticks

In Nozzle

Assembly

Increase wire speed until wire tip extends for a

distance equal to 3 x the wire diameter, outside

the Air Nipple

Feed roller tension insufficient

Check and adjust the feed roller tension, as in

Section …

Insufficient wire clearance in Nozzle

Clean out Nozzle bore with suitable drill

Clean wire with oiled pad or replace with fresh

wire, if the wire surface is badly damaged

Wire scuffing on Start/Stop Wire Guide

Check for wear on rear wire guide and for easy

opening and closing of the rollers

Wire stopped with extinguishing flame

(3/16” Fast – 1281 Nozzle System Only

Always extinguish the flame BEFORE stopping

the wire

Insufficient nozzle air pressure

Check parameter and reset air pressure

Loading...

Loading...