Page 44 of 64

5.1 Troubleshooting

When incurring any problem with the Flamespray process, it is necessary to first check that

the correct consumable parts i.e. Nozzle Assembly, are fitted and in good condition.

Spraying parameters should also be checked as per Section 8: Flowmeter Settings.

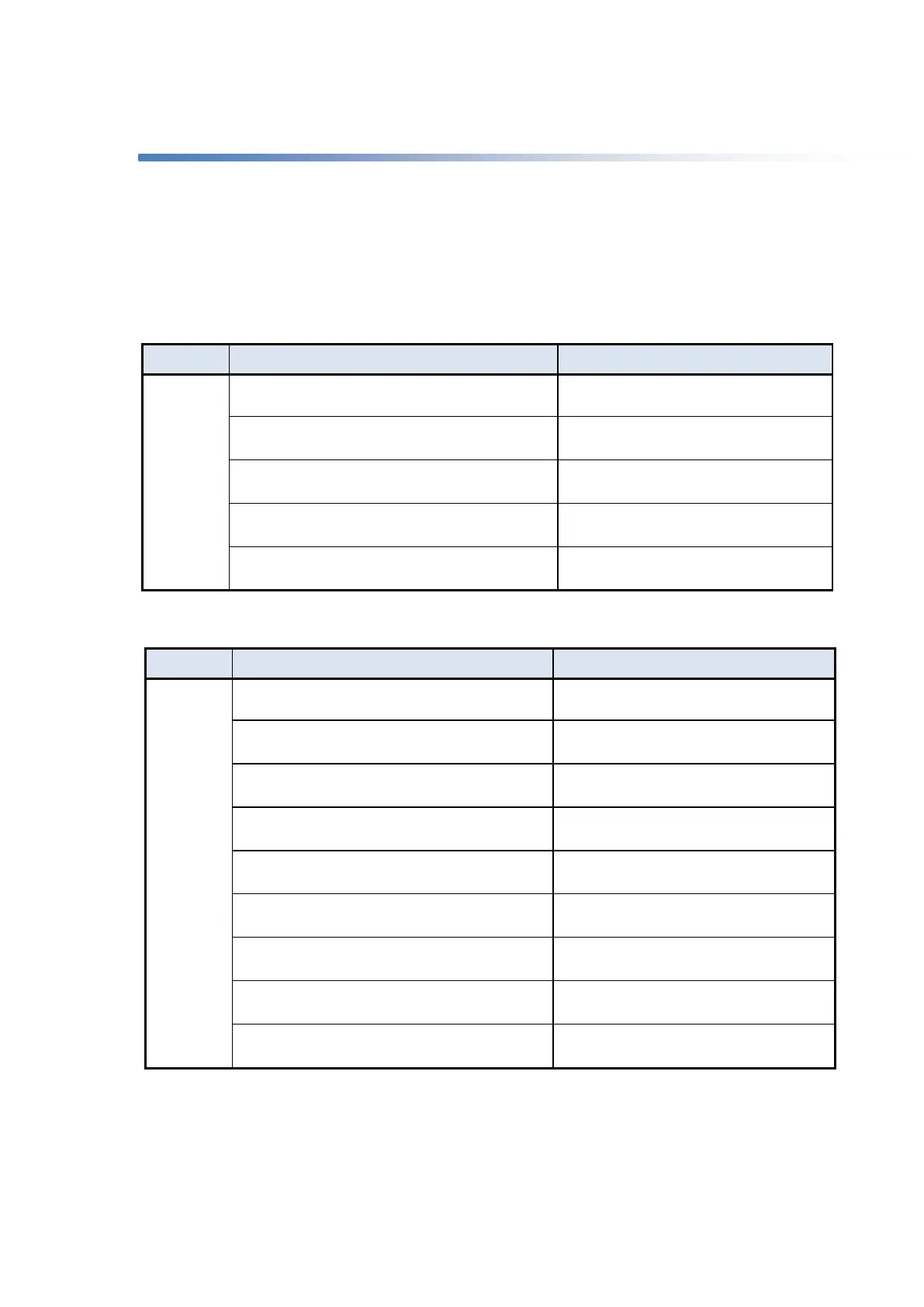

If the problem still persists, then consult the below tables. These are the most commonly

occurring problems, their causes and the action that should be taken to rectify the problem.

Spring Washer is weak, missing or damaged

Replace Spring Washer (1024)

Nozzle Assembly parts worn, dirty or damaged

Incorrect Nozzle Assembly

Replace with correct parts

Wire protruding too far forward from Nozzle

Pull wire back until flush with Nozzle front

face

Inspect ‘O’ Rings for damage or loss and

tighten Air Cover

Oversize gas holes in Nozzle Shell

Check that air, gas and oxygen pressures

are as recommended in Section…

Check part numbers (Section 7)

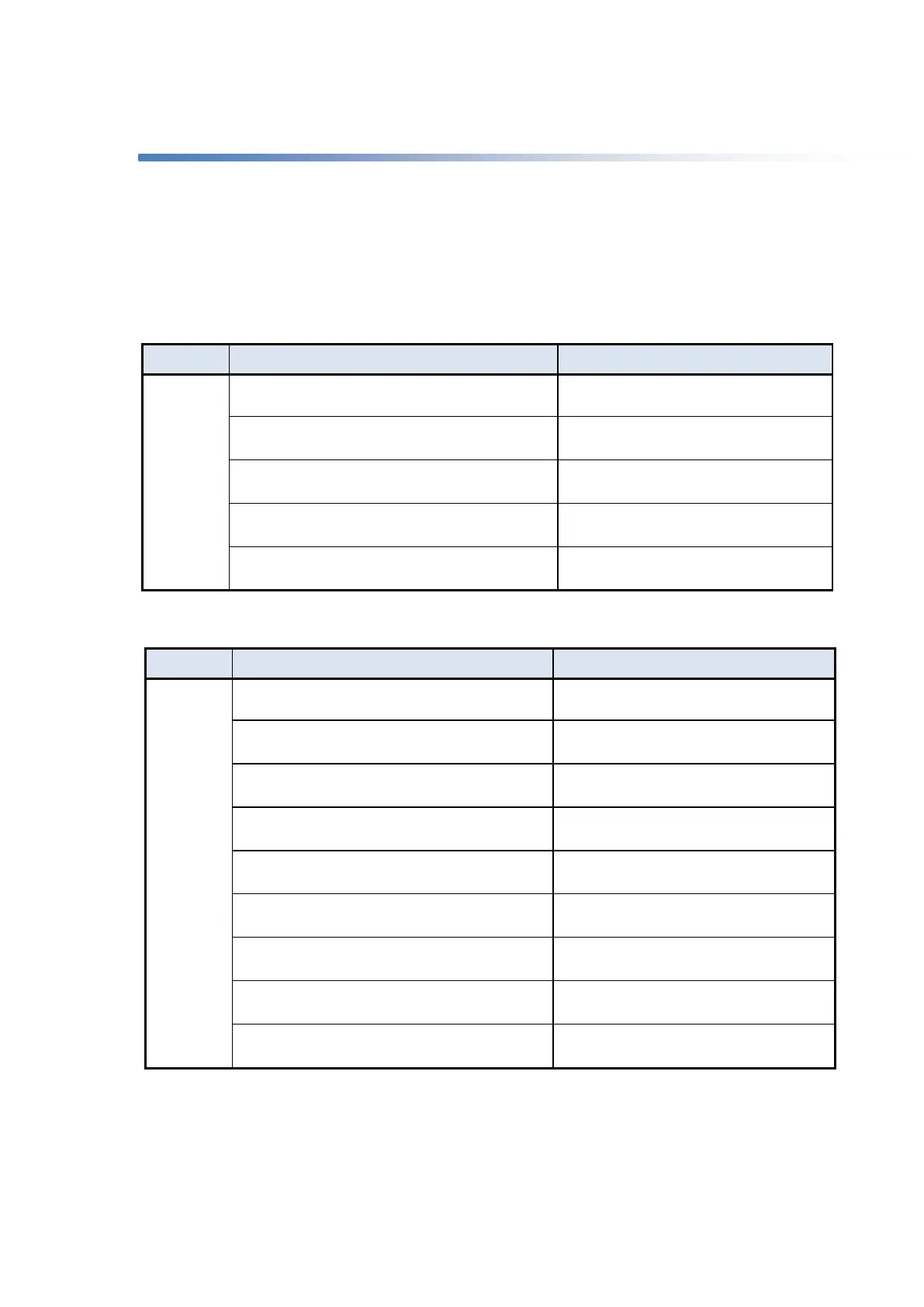

Restrictions in Oxygen/Gas holes in Mixing

Block

Check oxygen and gas ports and clean as

necessary

Carefully clean Air Nipple

Wire protruding too far forward from Nozzle

Pull wire back until flush with Nozzle face

Loading...

Loading...