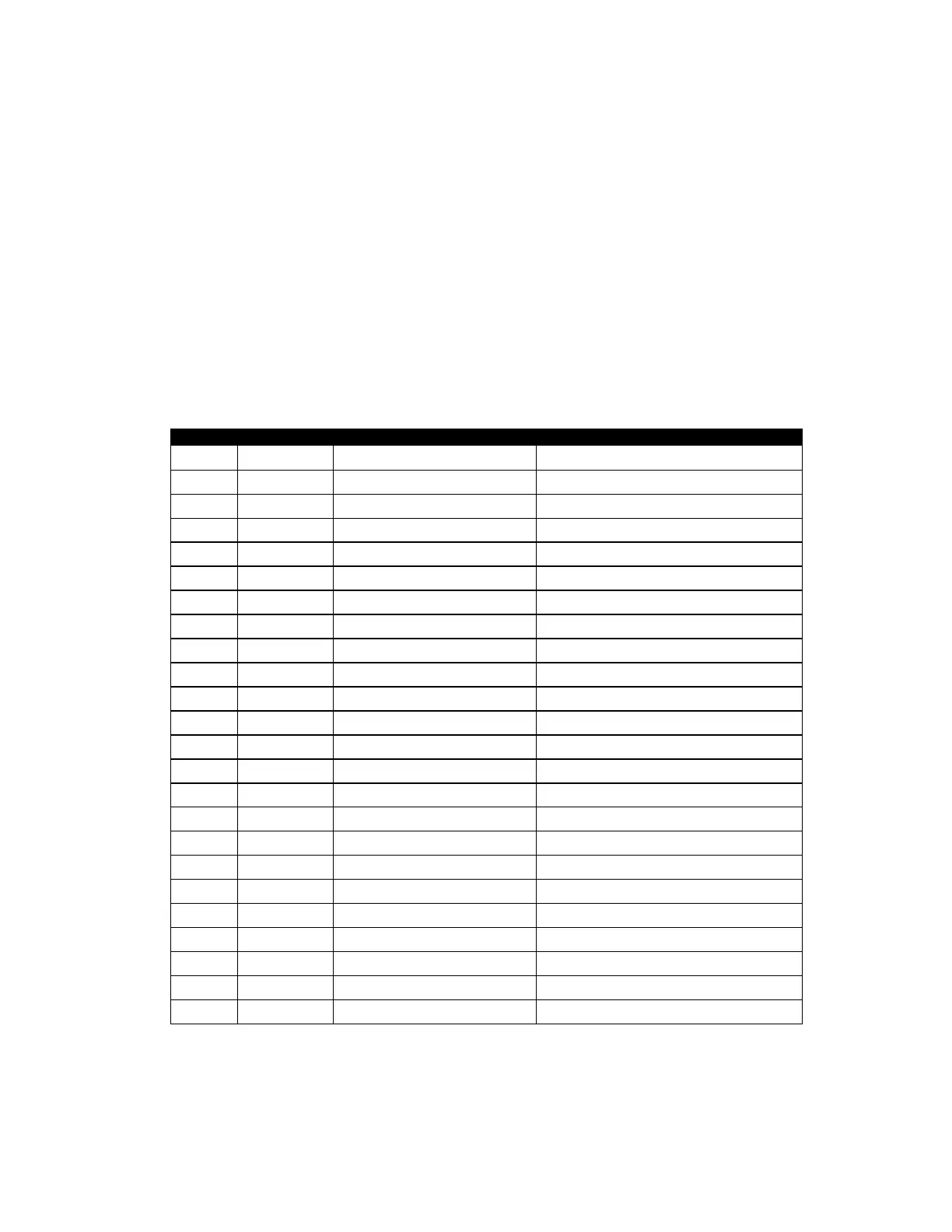

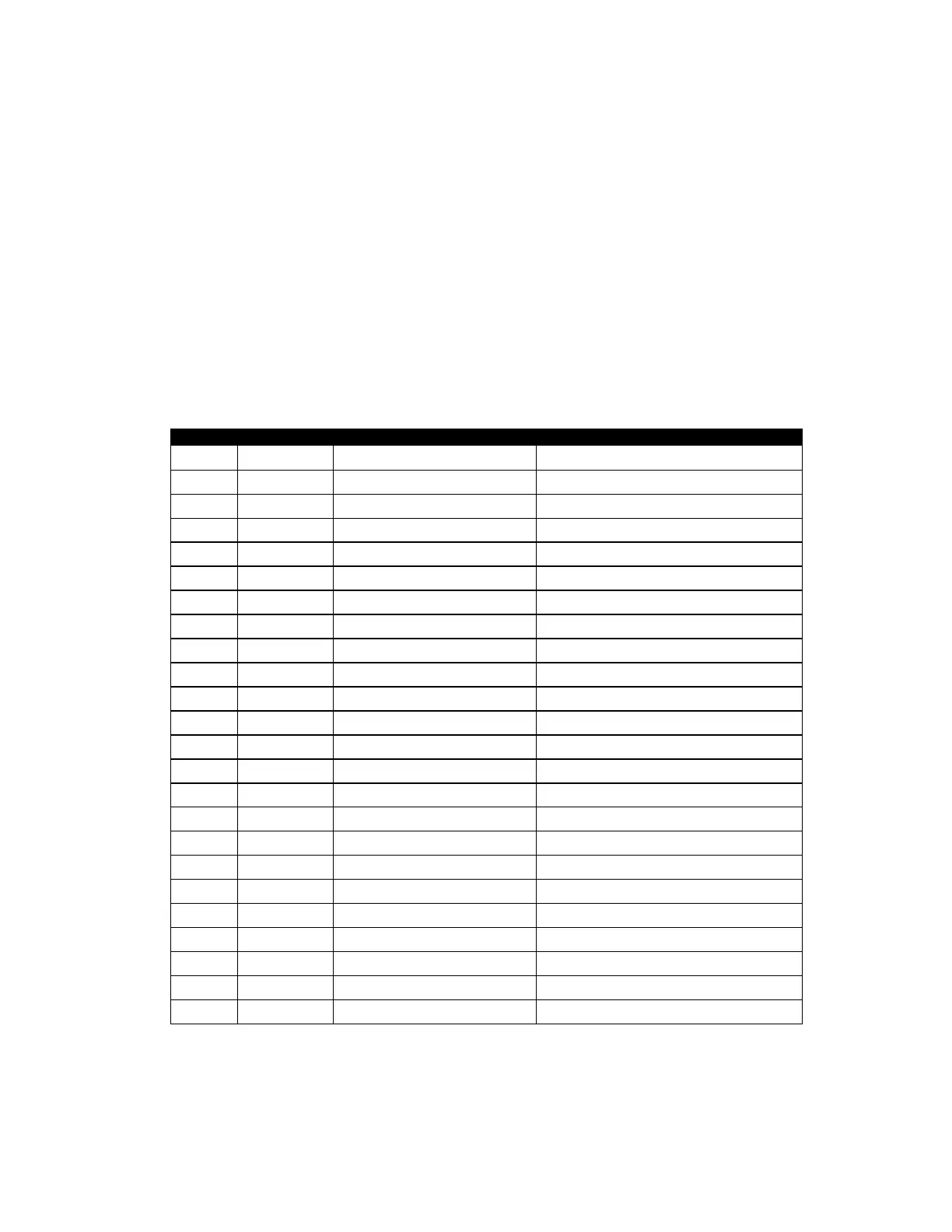

Manual Revision Record

This record page is for recording revisions to your QA-90 User and Service Manual that have been

published by METRON or its authorized representatives. We recommend that only the management

or facility representative authorized to process changes and revisions to publications:

• make the pen changes or insert the revised pages;

• ensure that obsolete pages are withdrawn and either disposed of immediately, or marked as su-

perseded and placed in a superseded document file, and;

• enter the information below reflecting that the revisions have been entered.

Signature of Person Entering Change

0 - Initial Release

Loading...

Loading...