1 GENERAL

1.1 Issues covered by the instructions

These instructions contain the most important user informa-

tion related to the actuators in the Metso Automation EJ

series. Further information on valves, positioners and other

accessories from the installation, as well as user and main-

tenance instructions for each specific model, can be ob-

tained.

1.2 Actuator design and function

EJ series actuators are double diaphragm actuators for

control and closure. The actuator is pneumatic and singular

function (model EJ). The basic principle of the actuator

relies on a floating central diaphragm cylinder design,

where a rolling diaphragm turns the valve stem via a

backlash-free gear transmission. No cylinder O-rings exist.

Because of the central floating diaphragm cylinder design,

the transverse internal forces, which affect and impose

friction on the actuator, have been eliminated. In addition,

the structure guarantees tolerance-free action as well as

exceptionally low internal friction. The mounting interface of

the EJ actuator conforms to ISO standard. The mounting

interface of the Metso Automation B1J cylinder actuator

conforms to the same standard, which makes the EJ actua-

tor and the B1J cylinder actuator interchangeable. A posi-

tioner (ND800) is attached directly onto the actuator, which

makes external tubing unnecessary. The actuator also has

a mounting interface which conforms to the VDI/VDE 3845

standard, and which allows connection of other accesso-

ries, such as positioners and limit switches, to the actuator.

This requires the use of external compressed air tubing. If

the actuator is used without a positioner, an additional

mounting interface for a solenoid valve is required on the

side of the actuator, according to the VDI/VDE 3845 stand-

ard. In such cases no external tubing is required. The

rotation of the drive shaft can be adjusted with stroke

adjustment screws which are located at each end of the

actuator.

1.3 Actuator labeling.

Attached to the actuator is a label (Figure 2) with the

following information:

1 Type code

2 Place and time of manufacturing and serial number

(yyyy ww nr)

3 Inspected by

4 Maximum supply pressure

5 Bar codes for items 1 and 2

1.4 Technical data.

Operating temperature:

standard design -20 °C to +70 °C

low temperature design -40 °C to +70 °C

high temperature design -20 °C to +120 °C

Maximum supply pressure: 8 bar / 116 psi

Cylinder volume, dm

3

/ in

3

:

EJ 05 0.17 / 10.5

EJ 07 0.4 / 24.5

EJ 10 1.0 / 61.0

EJ 12 2.5 / 152.5

EJ 14 6.0 / 366.0

Nominal torque with standard spring, Nm / lbf ft:

EJ 05 19 / 14

EJ 07 47 / 34.5

EJ 10 117 / 86.5

EJ 12 280 / 206.5

EJ 14 690 / 509

The output torque of the actuator depends directly on the

supply pressure.

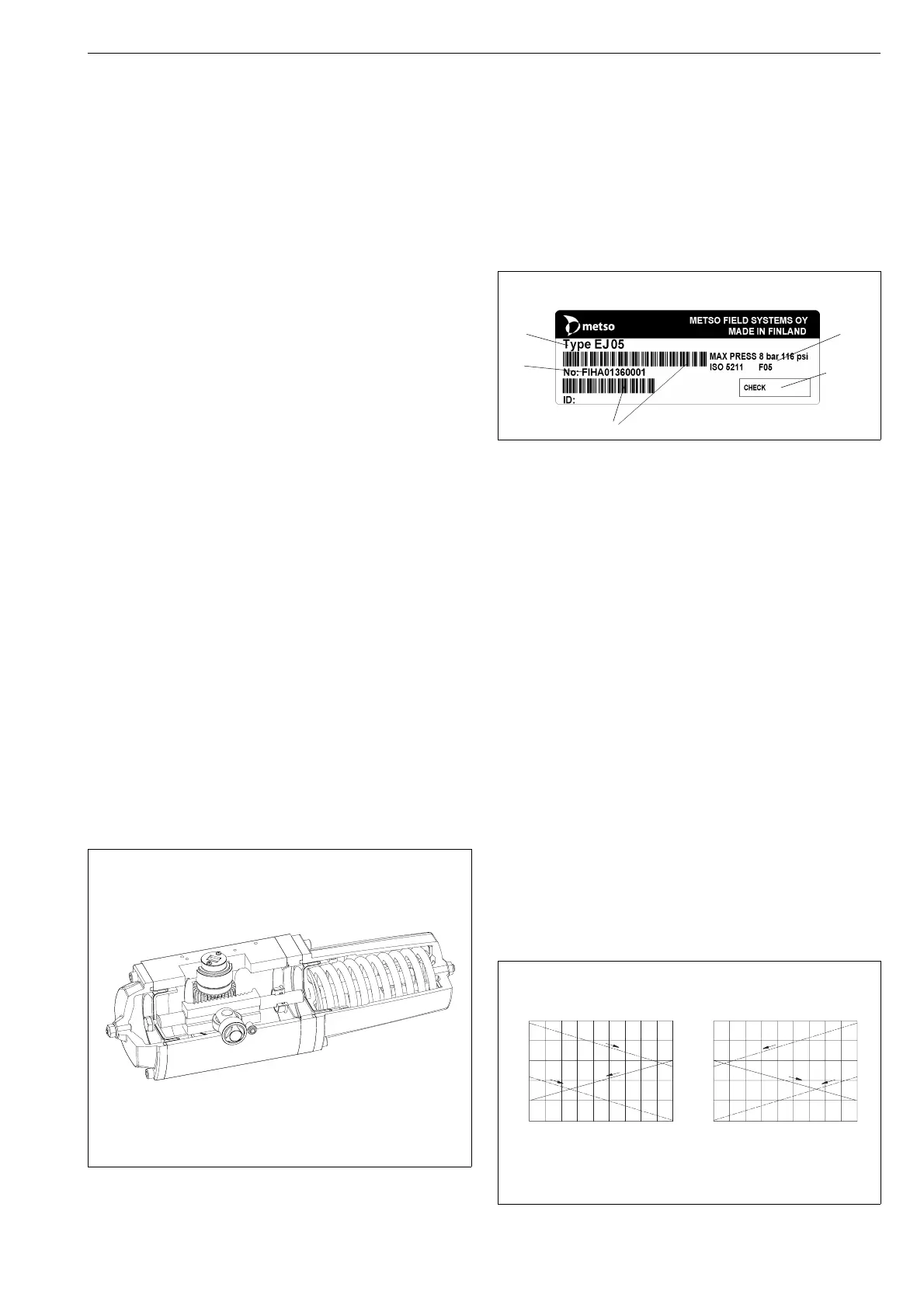

The operational direction or turning angle of the actuator

affects the output torque, Figure 3.

Fig. 1. Actuator design

1

4

3

2

5

Fig. 2. ID label markings

1.8

1.6

1.4

1.2

1

Mn

M / Mn

0102030405060708090

angle /

EJ_A

1.8

1.6

1.4

1.2

1

Mn

M / Mn

0102030405060708090

angle /

EJ

M

5 bar

M

4 bar

M

spring

M

5 bar

M

4 bar

M

spring

Fig. 3. The influence of the turning angle on the

torque

3

Loading...

Loading...