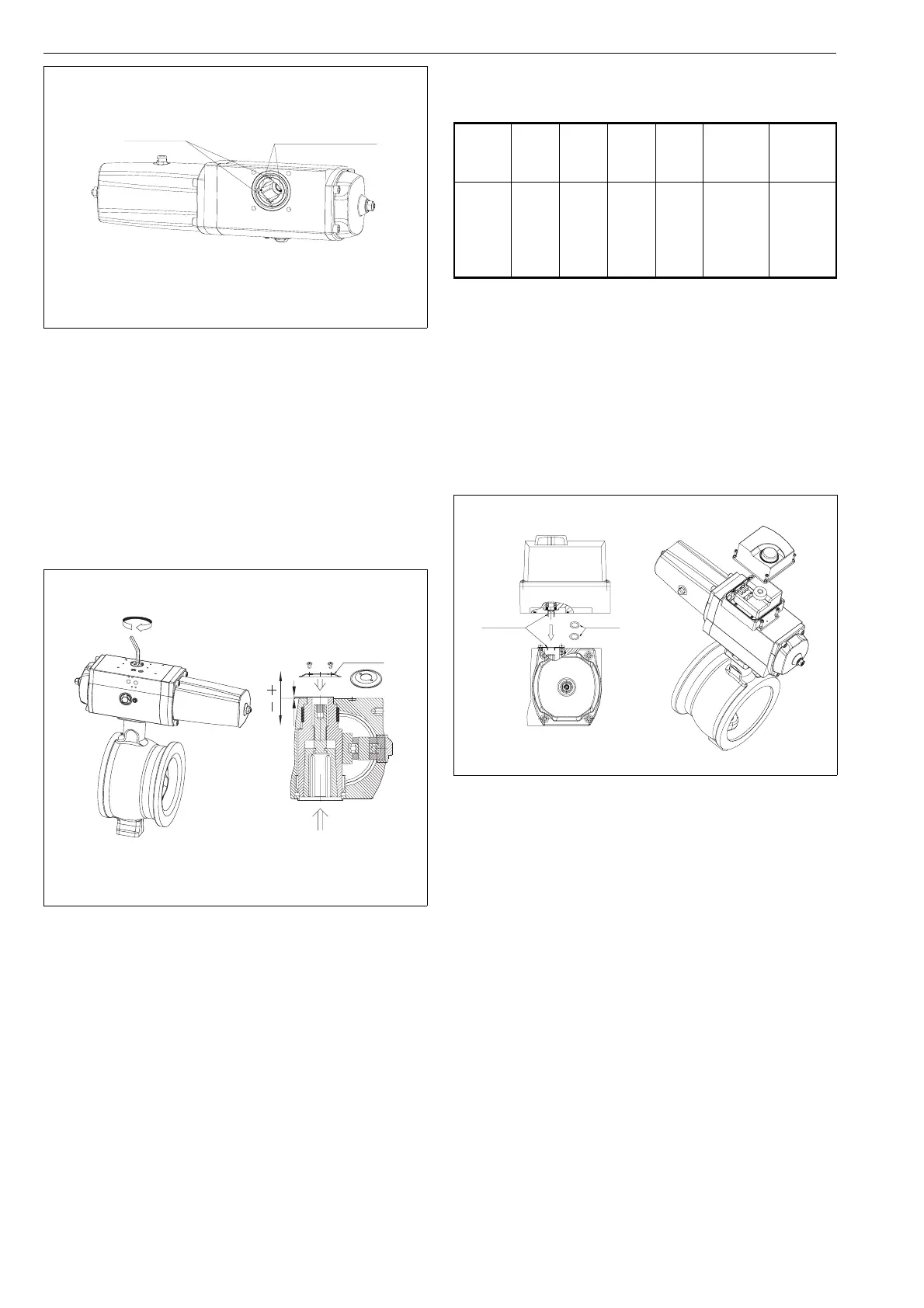

The actuator design allows axial movement of the drive

shaft. Check, before the screw is tightened, that the drive

shaft is in the upper position of its axial movement, which

is its normal position (the mounting position shown in Figure

8). Checking is important, as the actuator shaft drops down

slightly when the screw is tightened. The axial movement

of the drive shaft can be observed and measured before

attachment to a valve. The actuator drive shaft is in the

upper position when its upper surface conforms to Table 2

(see Figure 8).

The drive shaft will automatically find its correct position

when the tightening screw is tightened, if the installation tool

is used (See Figure 8). The installation tool is attached

instead of the coupling plate using M4 screws with the drive

shaft in upper position (before the valve is installed). Tighten

the screws in such a way that the tool is tightened against

the upper surface of the housing.

Install the actuator on the valve and attach the attachment

screws normally. Finally, tighten the tightening screw ac-

cording to Table 2. The required torque is also marked on

a plate close to the drive shaft on the actuator housing. The

installation tool is removed, and the coupling plate is reat-

tached.

The valve may malfunction if the tightening of the connec-

tion has been carried out improperly.

Finally, the extreme positions of the valve are adjusted with

the stop screws at the ends of the actuator. The location of

the screws for adjusting the Close and Open positions of

the valve are marked with letters on the ends of the actuator

housing (see Figure 5).

3.3 Attaching the ND800 valve controller

to the actuator

The ND800 valve controller is attached directly to the

actuator with four attachment screws. No tubing is required

between the devices. Two of the attachment screws are

located at the front of the actuator and two below the cover.

O-rings are placed in the air connections of the positioner.

The valve controller shaft is correctly positioned when the

painted position marks are aligned (see Figure 9).

External tubing is necessary if a reverse signal function is

required. See the ND800 installation, user and mainte-

nance instructions 7 ND 70 for further information.

Attachment of the ND800 valve controller to the EJ05

actuator is done using a connection plate (see Figure 10).

Make sure that the pegs of the connection plate are pointing

away from the actuator. The plate is attached to the actuator

with four attachment screws. In addition, O-rings are placed

in the grooves below the plate. The ND800 valve controller

is attached next, as described previously.

Size Mount. Thr. Hex.

size

Nm ~X

upp. pos.

(mm)

~X

lower pos.

(mm)

EJ05

EJ07

EJ10

EJ12

EJ14

F05

F07

F10

F12

F14

M12

M16

M20

M24

M36

6

8

10

14

19

25

50

100

200

700

4,0

1.5

2.5

3.5

4.5

1

-2

-2

-2

-2

Table 2. Mounting interfaces, tightening screws, tight-

ening torques and drive shaft movement

DIN keyways in the

middle of bushings

ANSI keyways at the

bushing split

THE ACTUATOR IN CLOSED POSITION

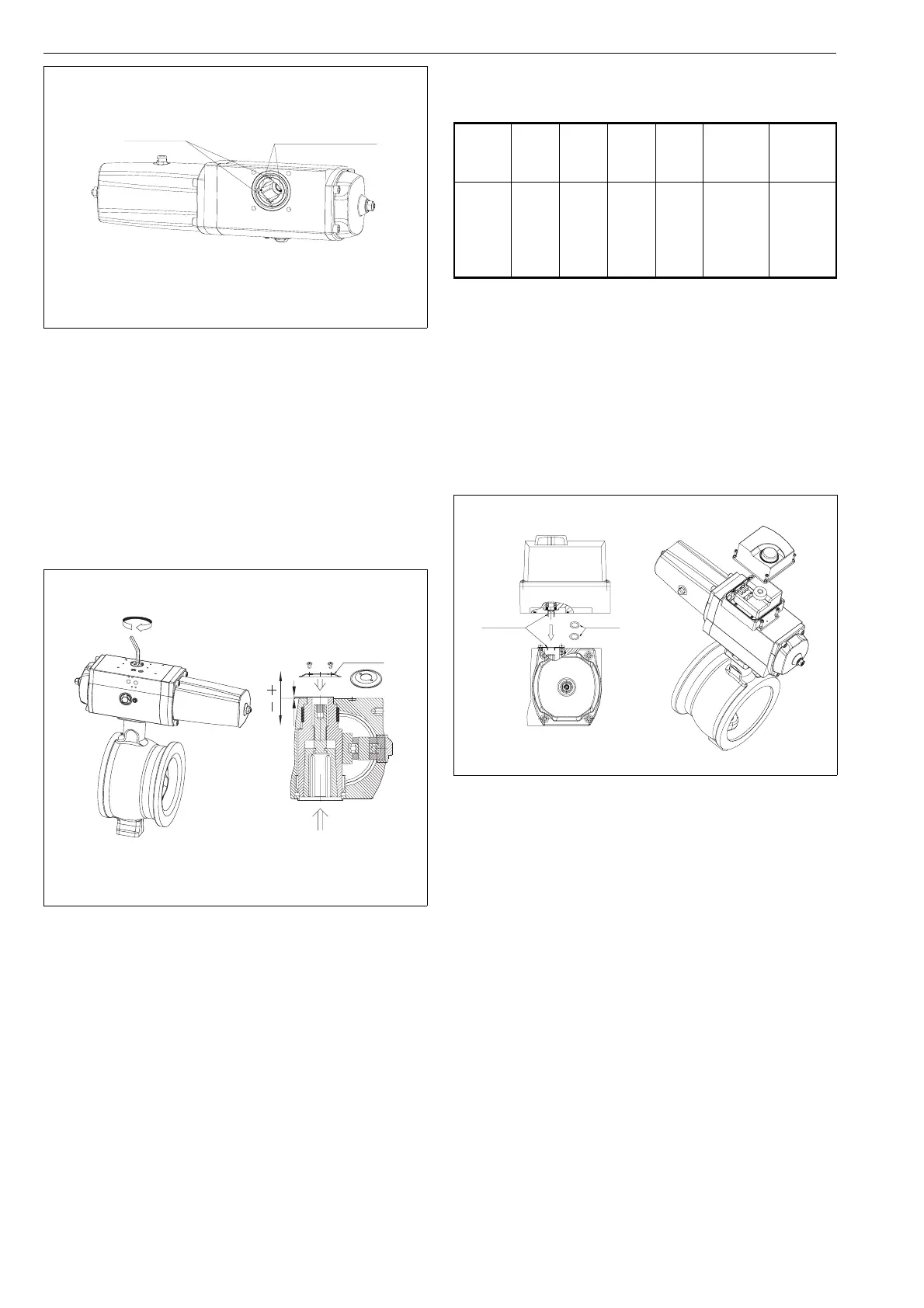

Fig. 7 Keyway positions on the actuator

X

Installation

tool

Fig. 8. Tightening of the cone bushing

O-rings

Painted

alignment

marks

Fig. 9. Attaching the ND800 valve controller to

the EJ actuator

6

Loading...

Loading...