Fix the cylinder end with the socket head screws (22),

once it is in the right position. Tighten the screws

according to the torque values given in Table 3.

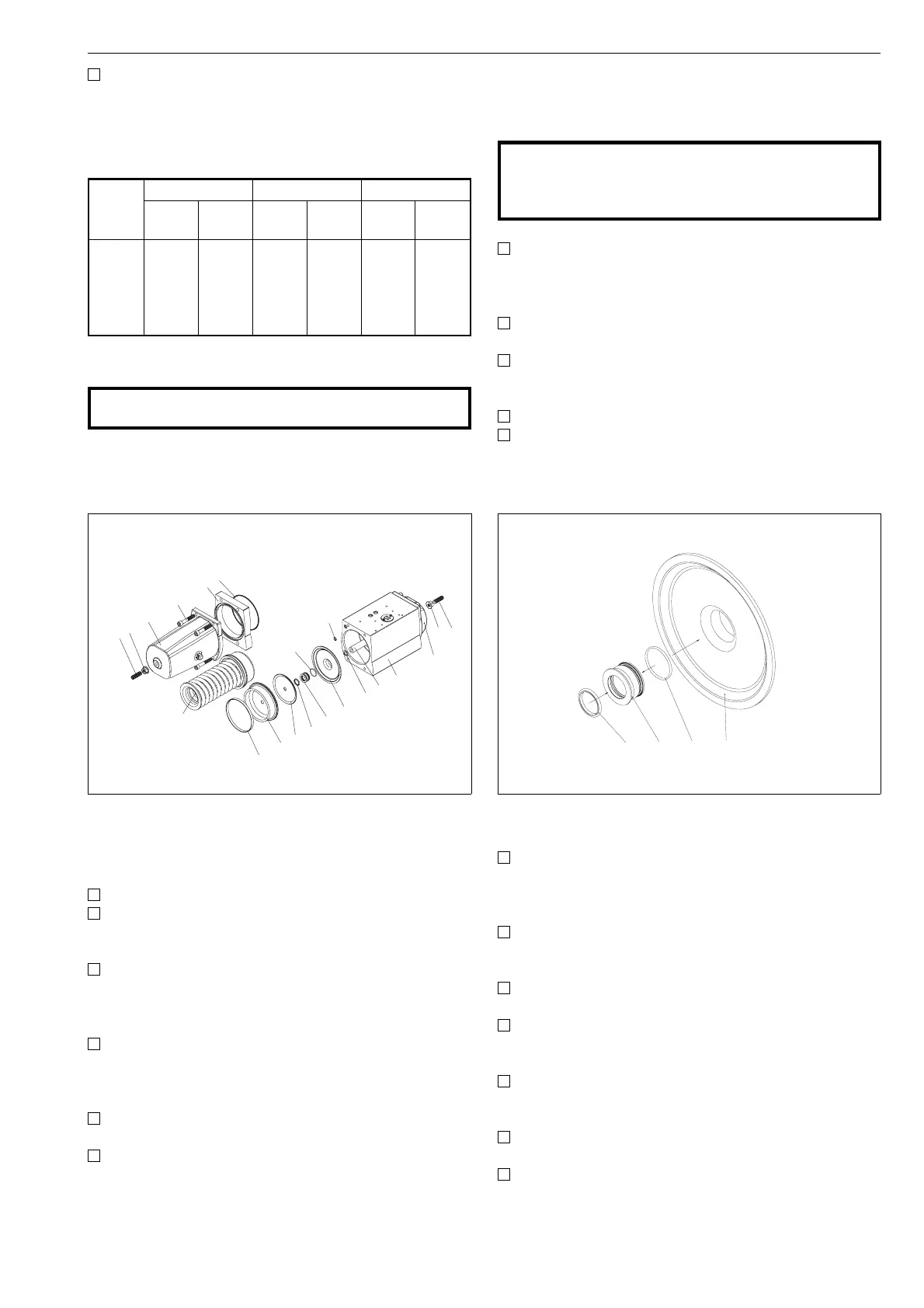

4.1.2 Exchanging diaphragm at the spring end

WARNING:

Do not dismantle a pressurized actuator!

The seal ring (50) should be exchanged together with the

membrane. Bearings (47, 49), O-rings (20, 59, 52) and seal

ring (51) are exchanged when required.

The diaphragm in the spring-less end is exchanged in the

following way:

Make sure that the actuator is depressurized.

Remove the nut (24) and the stop screw (23) from the

end of the spring housing (42). Remove the nut (24)

and the stop screw (23) from the cylinder end (2) also.

Remove the socket head screws (53) of the spring

housing (42) by gradually and sequentially turning

each one. The spring housing will maintain the com-

pression of the spring package.

Turn the screws evenly (ca. 5 mm or 3 full turns) until the

spring housing (42) has released the spring package

compression. Then remove the socket head screws (53)

completely from the housing (1).

Remove spring housing (42), spacer plate (45), O-

ring (52) and O-ring (20) from the housing (1).

Remove the bearing (49) from the spring package and

remove the package from the gear rod (4) by turning it

open. The spring package can also be turned by the

nut (54) at the end of the package. The nut has been

permanently fixed and must not be detached from

the spring package.

WARNING:

The spring package must not be dismantled, as the

spring will still be compressed after the package has

been detached.

Following the detachment of the spring package, the

following parts can be removed from the gear rod

(4): rolling diaphragm (7), diaphragm support plate

(6) and seal ring (51).

Remove the lead-through plate (46) from the gear

rod (4) by pulling it away from the housing (1).

Remove the lead-through bearing (47) from the lead-

through plate (46) and the seal ring (50) from the

lead-through bearing.

Check the lead-through bearing and replace it if it is worn.

Lubricate the new seal ring (50) with Unisilikon

GLK122 or Molykote III lubricant or similar, and install

it in the lead-through bearing (47).

Install the O-ring (59) in the groove on the outer

surface of the lead-through bearing (47). Then attach

the lead-through bearing (47) to the lead-through

plate (46) using a suitable pressing tool.

Press the lead-through plate (46), the lead-through bear-

ing (47) and the seal ring (50) onto the gear rod until the

lead-through plate (46) touches the housing (1).

Install the O-ring (20) in the groove at the end of the

housing (1).

Check and remove loose particles from the spring

retainer (41), the diaphragm support plate (6) and the

spacer plate (45) at the end of the spring package.

Lubricate the grooves in the spacer plate (45) with

Unisilikon GLK112 or Molykote III lubricant or similar,

and install the O-ring (52) in the groove.

Place the spacer plate (45) and the O-ring (52) on

the housing (1) and the lead-through plate (46).

Next the rolling diaphragm (7) is prepared as shown

in Figure 15 of Section 4.2.1.

20

24 23

2

1

4

51

46

47

50

6

7

49

54

23

24

42

53

45

52

59

Note:

Part 59: only EJ07-14

Fig. 17 Exchange of membrane at the spring end

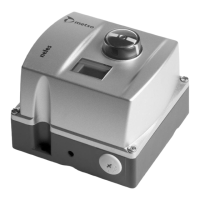

50 47 59 46

Note:

Part 59: only EJ07-14

Fig. 18 Installation of lead-through bearing and

seal ring

Actu

ator

Screw (22, 53) Screw (25) Spring package

Thread Nm Thread Nm Hex.

size

Nm

EJ 05

EJ 07

EJ 10

EJ 12

EJ 14

M6

M8

M10

M12

M16

8,3

20

40

69

170

M8

M10

M12

M16

M20

10

15

25

40

60

13

19

24

30

36

10

15

25

40

60

Table 3. Screws (parts 22, 25 and 53) and spring pack-

age, tightening torques

9

Loading...

Loading...