2 TRANSPORTING, RECEIVING AND

STORING

Check that neither the actuator nor its accessories have been

damaged during transportation. Store the actuator carefully

prior to installation, preferably indoors in a dry place. Do not

transfer it to the installation point or remove the end caps until

immediately prior to the installation. If the actuator diaphragms

are separately stored, storage should be carried out accord-

ing to general rules covering the storage of rubber products.

The equipment should be stored in a dry place at room

temperature, protected from UV radiation. The diaphragms

are packed in a non-transparent plastic bag that should not

be opened unnecessarily.

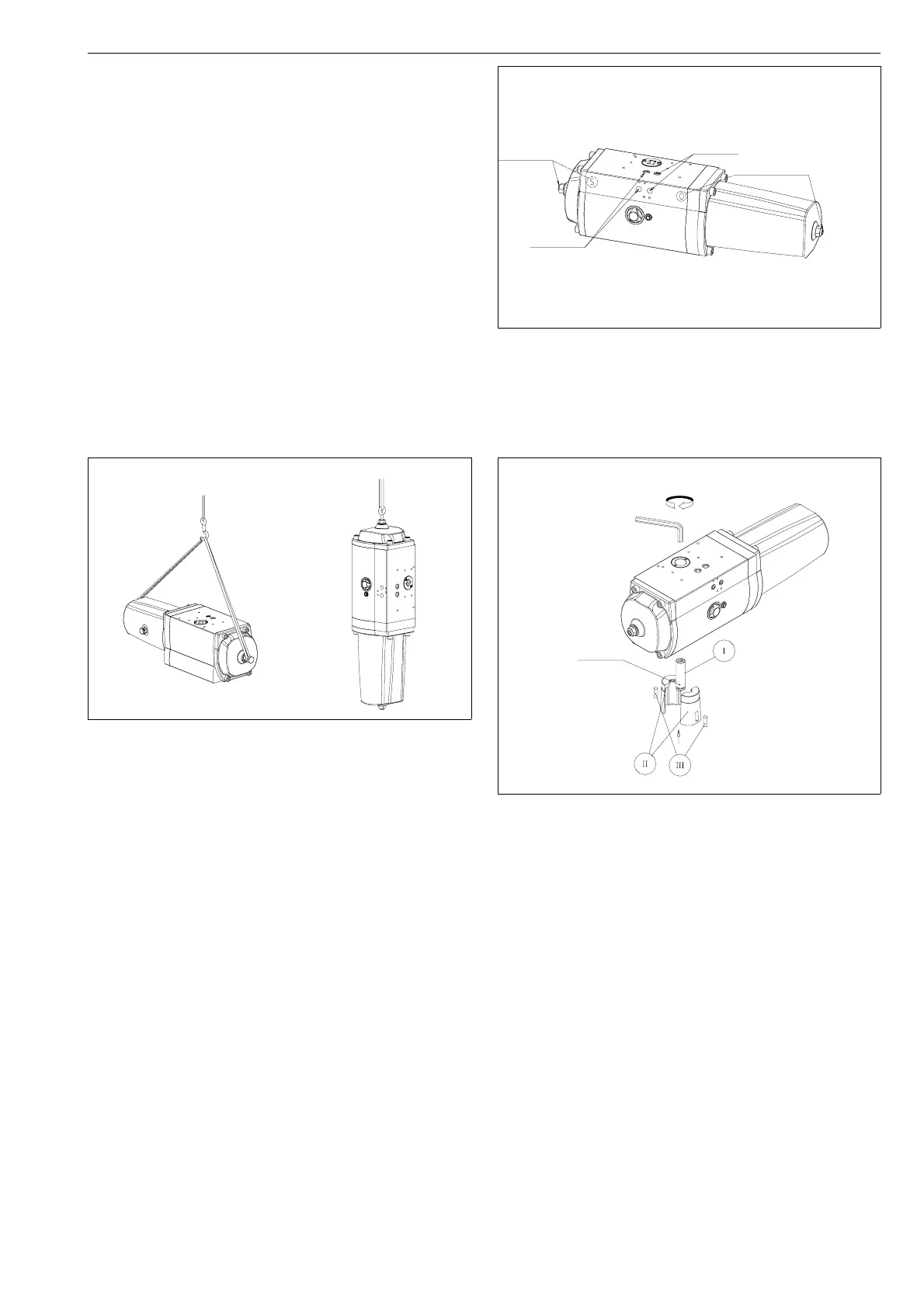

Lift the actuator as shown in Figure 4: In the horizontal

position by sufficiently long hexagon screws which replace

the adjustment screws, in the vertical position by an eyebolt

which replaces the adjustment screw. Check the weights

from the table in Section 9.1.

3 INSTALLATION AND DISMANTLING

3.1 Operating fluid

Double diaphragm actuators use dry compressed air or

natural gas. Oil spray is not required. Actuators equipped

with positioners use clean, dry and oil-free compressed air.

The air connections are shown in the dimensional drawing

9.2. (Dimensions). The maximum supply pressure for the

actuator is specified on the label (Figure 2). See also

Section 1.4 "Technical data".

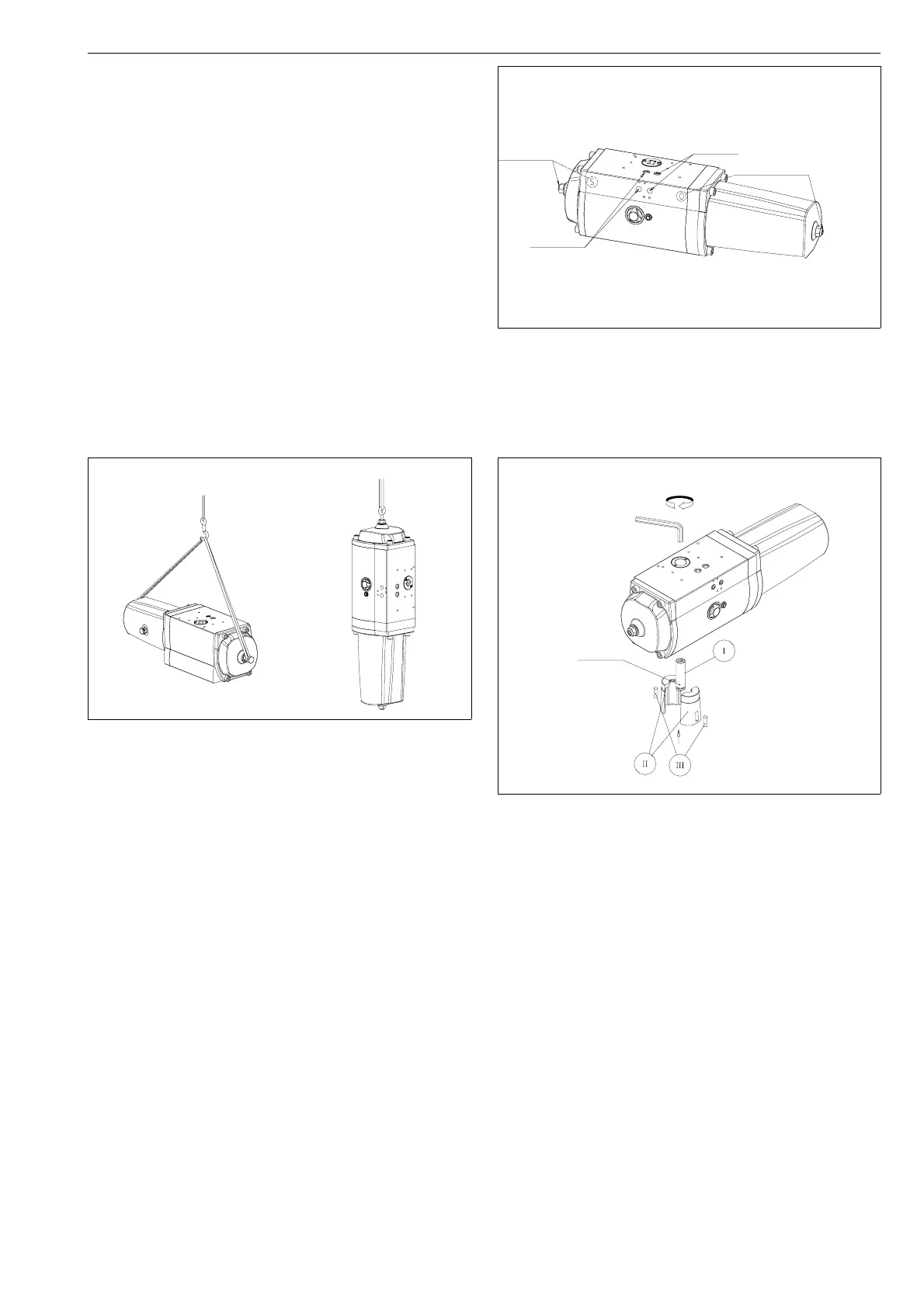

3.2 Attaching the actuator to a valve

The actuator is attached to a valve via an ISO 5211 standard

mounting interface. The actuator bore is adapted to the

valve stem with a separate coupling. The coupling (II+II) is

a two-piece, cone-shaped bushing, which is tightened

firmly with a tightening screw (I) around the valve stem.The

coupling and the tightening screw are mounted from the

mounting interface side of the actuator, according to Fig-

ure 6. Cylindrical pins (III) are inserted in the bushing slots,

and these must be directed into the corresponding slots in

the actuator during tightening. The threads of the tightening

screw must be carefully cleaned of old threadlock before

the coupling and the tightening screw are installed, and

Loctite 243 or similar threadlock must be carefully applied to the

threads, as shown in Figure 6. The tightening screw can be turned

from inside the actuator shaft using a suitable hex key, see Figure 8.

Prior to installation, the correct keyway position of the valve

must be checked. The coupling has four keyways, two of

which are intended for valves with DIN key (for example RA

or RB segment valves) and two for valve shafts with ANSI

keys (for example all old type Neles valves). The DIN

keyway is located in the middle of the half bushing, and the

ANSI keyway is located in the split between the bushing

halves. Figure 7 shows the keyway position when the

actuator is in a closed position.

The Open or Closed positions of the actuator can be identified

either by using compressed air, see Figure 5, or by checking

the position of the pointer at the end of the drive shaft. The

actuator is closed if the pointer on the coupling plate is

transverse to the direction of the actuator’s main shaft.

The actuator is either mounted directly on the valve, or is

attached to the valve bracket with four screws. The tighten-

ing screw of the coupling should be loosened before

mounting, to allow the shaft to fit easily into the actuator.

Fig. 4. Lifting the actuator

Closing pressure

Adjustment screw

for closed position

Adjustment screw

for open position

Opening

pressure

Fig. 5. Actuator connections

Loctite 243

or similar

Hex. key

Fig. 6. Cone bushing installation

5

Loading...

Loading...