Operating Instruction X-Type plus

Operating instructions X-Type plus V1-3.docx Page 43 of 45

10. Maintenance of the Synchroprint

The Synchroprint has been designed to operate ‘maintenance-free’ as far as possible. Only a few

important service measures are necessary by the operator.

Remove all residues from the Synchroprint remaining

from production materials such as inks and adhesives

etc. Clean, tidy and sweep the printshop area.

Check inspection glass on

water separator/trap

The inspection glass of the water separator/trap must

be checked for condensed water. The level must not

exceed the red mark; otherwise the automatic relief

aperture may become clogged or defective.

Wash off all anodized parts of the Synchroprint with

an appropriate cleaner. Clean all inspection glasses

and displays. Clean or replace the protective foil on

the touch screen.

Cleaning the Control

Panel

The control terminal must only be cleaned with a dry

cloth or appropriate monitor-cleaning cloth. If any

aggressive cleaners or solvents are applied, the surface

of the keypad will be damaged or destroyed, resulting

in cancellation of the warranty.

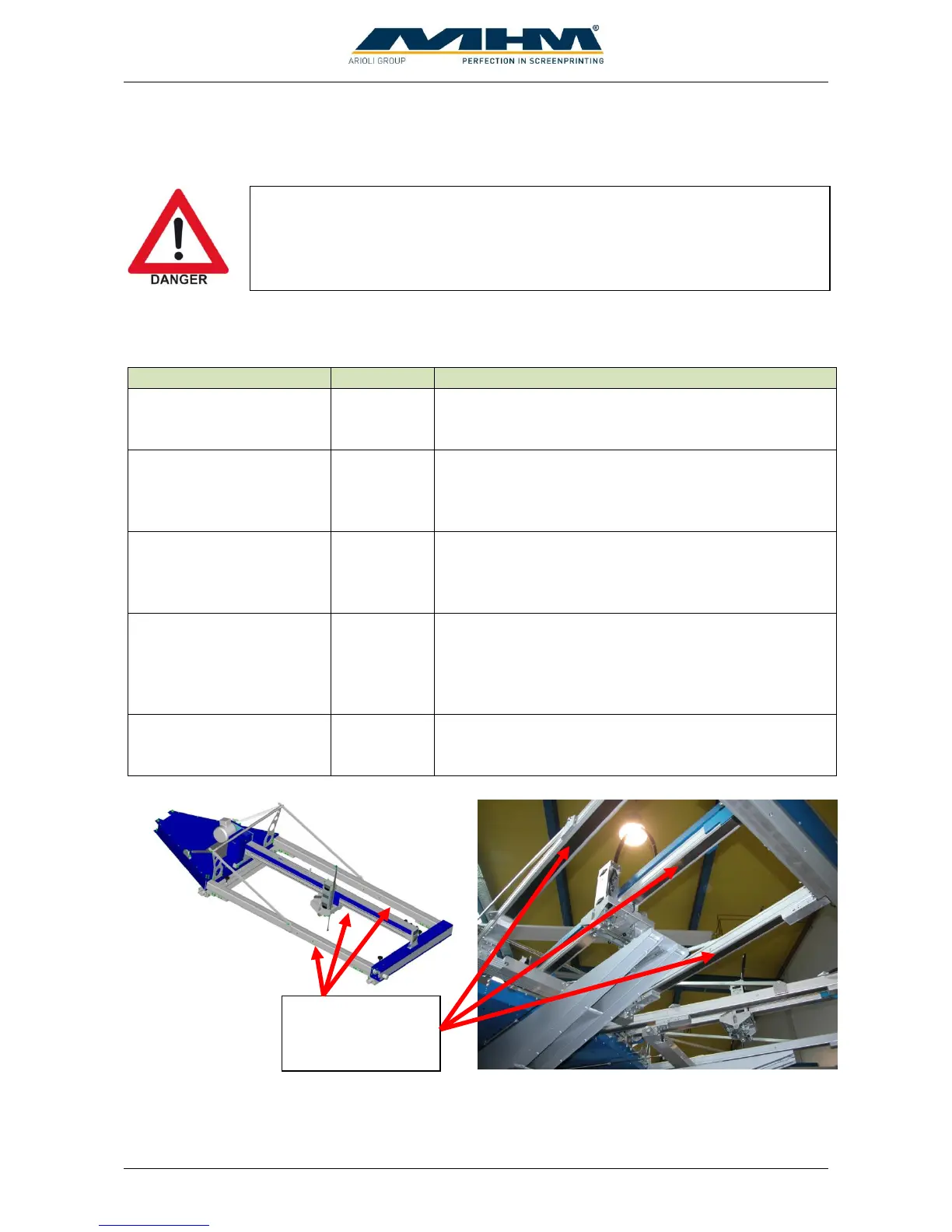

Wipe clean the sealing

band on the underside of

all the linear profiles

The sealing band on the underside of the linear

profiles must be wiped clean thoroughly and

lubricated with an oil-soaked cloth.

Sealing band on

the underside of

the linear profiles

Before doing maintenance work the machine must be cut off from the supply

voltage using the main power switch).

Loading...

Loading...