Microstep Website http://www.microstep.cc/eng

北京欣斯达特数字科技有限公司 Beijing Flourishing Start Digital Technology Co., Ltd

page: 16

when program is huge, it takes longer time to treat, then can choose No Pretreat Graph

(figure), set figure’s max/min value in advance, controller draws and cuts at the same time

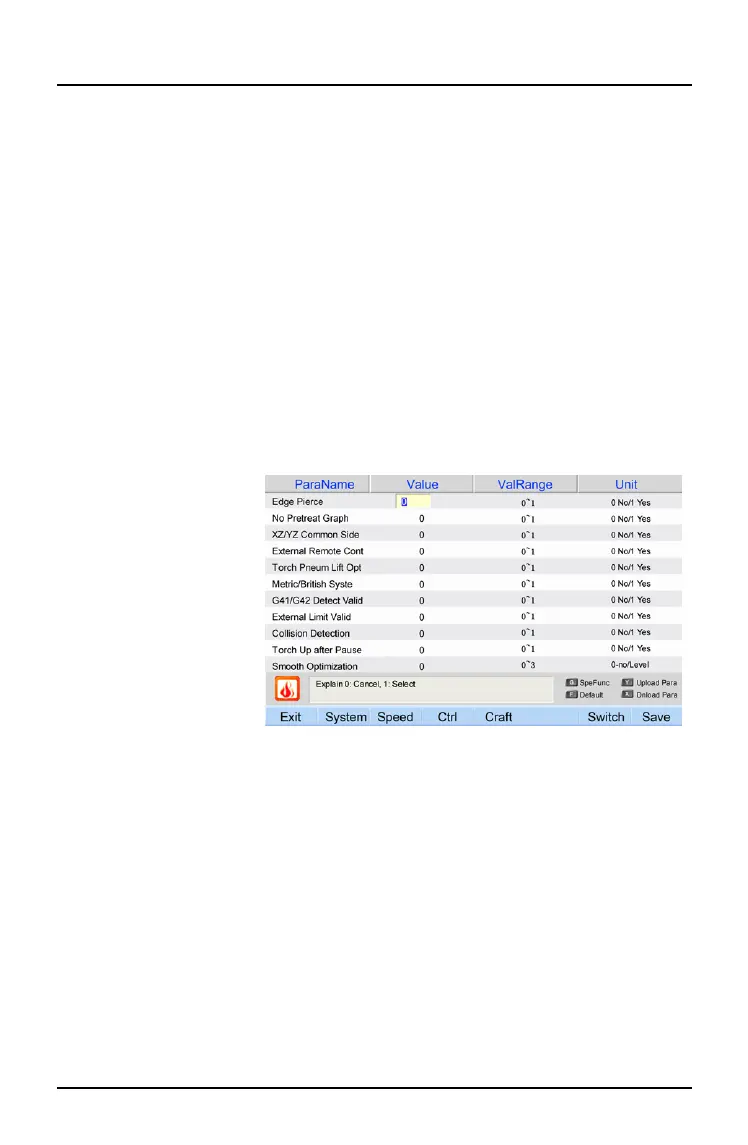

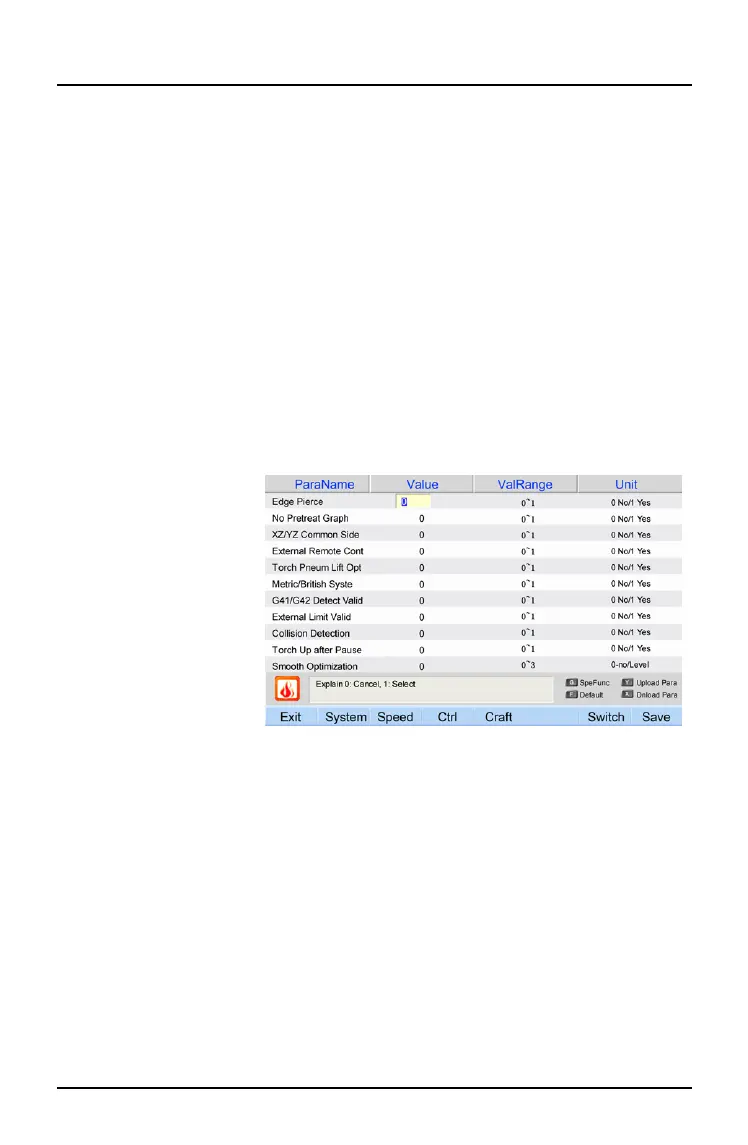

5.3.3 XZ/YZ Common Side: 0 is X/Z synchronizes movement control, 1 is Y/Z synchronize

movement control, also dual drive

6.3.4 external remote control: 1 is to choose external remote control

5.3.5 Metric/British Syste (metric/British system): 0 is not to choose, 1 is to choose. When

choose 0 metric system, length, speed and coordinate are all mm, and can run British system

program (G20), but show metric system (mm). When choose 1 British system, length, speed

and coordinate are all inch, and can run metric system program (G21), but show inch

5.3.6 External Remote Cont (external remote control): use it to choose 1, no is 0

5.3.7 G41/G42 Detect Valid: check whether compensation (G41/G42) is right. When error is

not serious, choose 0, tip error line, but no alarm, continue to run program

5.3.8 Torch Pneum Lift Opt (torch pneumatic lifting): cut thin plate, pneumatic lifting is

better than auto torch height controller, choose 1, and torch down is valid, torch up is

invalid, torch down is in keep state.

5.3.9 External Limit Valid: many small cutters are so simple without external hardware limit,

5.2.3 Buff Speed (buffer speed): in order to reduce the shock from cutting machine run at

high speed, set a lower buffing speed, usually for a machine with soft steel working table

and high speed, If don’t use the function, and can set it same as “speed limitation”

5.2.4 Speed Limitation: top cutting speed, unit: mm (or inch)/min

5.2.5 Manual Speed Limitatio: running speed in manual mode, unit: mm (or inch)/min

5.26 Idle Run Speed: running speed without load (G00 rapid point movement speed), unit:

mm (or inch)/min

5.2.7 Reset Speed: speed of back to machine zero, unit: mm (or inch)/min

5.2.8 Back Speed: speed of backward, unit: mm (or inch)/min

5.2.9 Arc Transition: whether choose arc transition when corner, 1 is valid, o is invalid

5.2.10 speed down coefficient: speed down ratio at corner according to machine inertia,

rigidity and other factors

5.2.11 speed adjustment angle: set it according to machine inertia, rigidity and other

factors, when smaller than the angle, controller doesn’t adjust speed.

Note: speed parameters and machine characteristics have close relations.

5.3 Enter Ctrl (control) interface

5.3.1 Edge Pierce: 0 is not

to choose, 1 is to choose

(when pierce point, a tip

will appear “LocalPie

(pierce at current

position), EdgePier (out

edge pierce), NoPierce”)

5.3.2 No Pretreat Graph:

u s u a l l y f i r s t l y t r e a t

p r o g r a m , m e a s u r e

figure’s max/min value,

Loading...

Loading...