Microstep Website http://www.microstep.cc/eng

北京欣斯达特数字科技有限公司 Beijing Flourishing Start Digital Technology Co., Ltd

page: 17

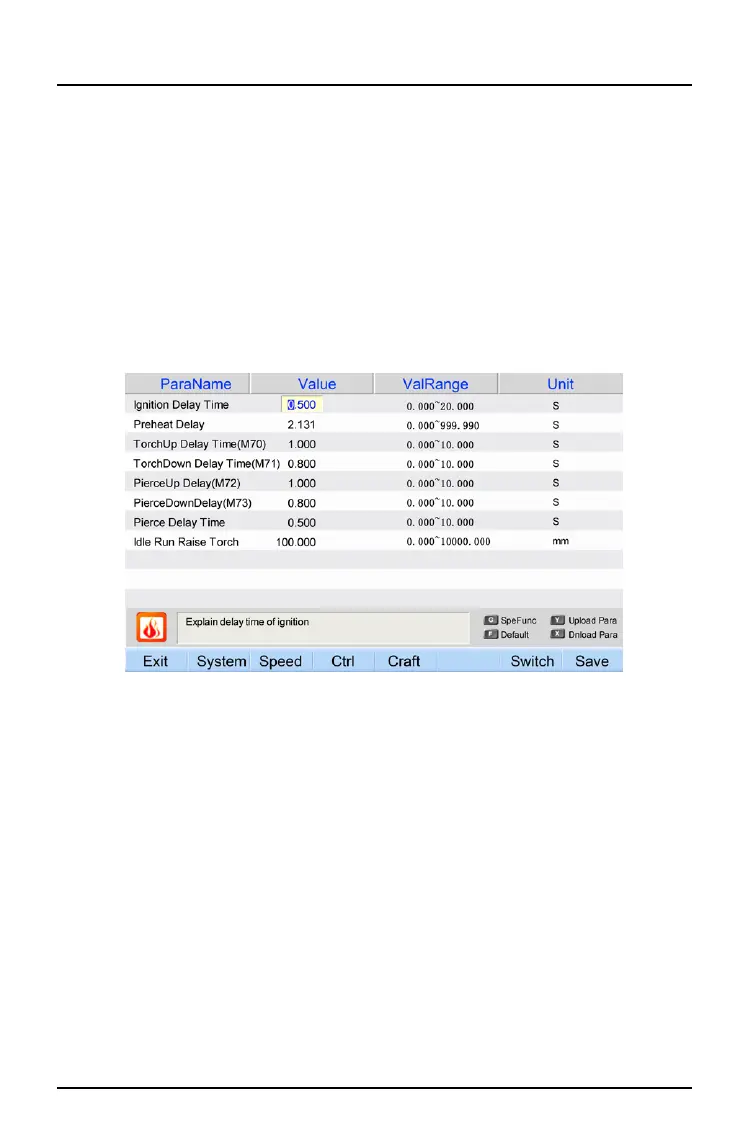

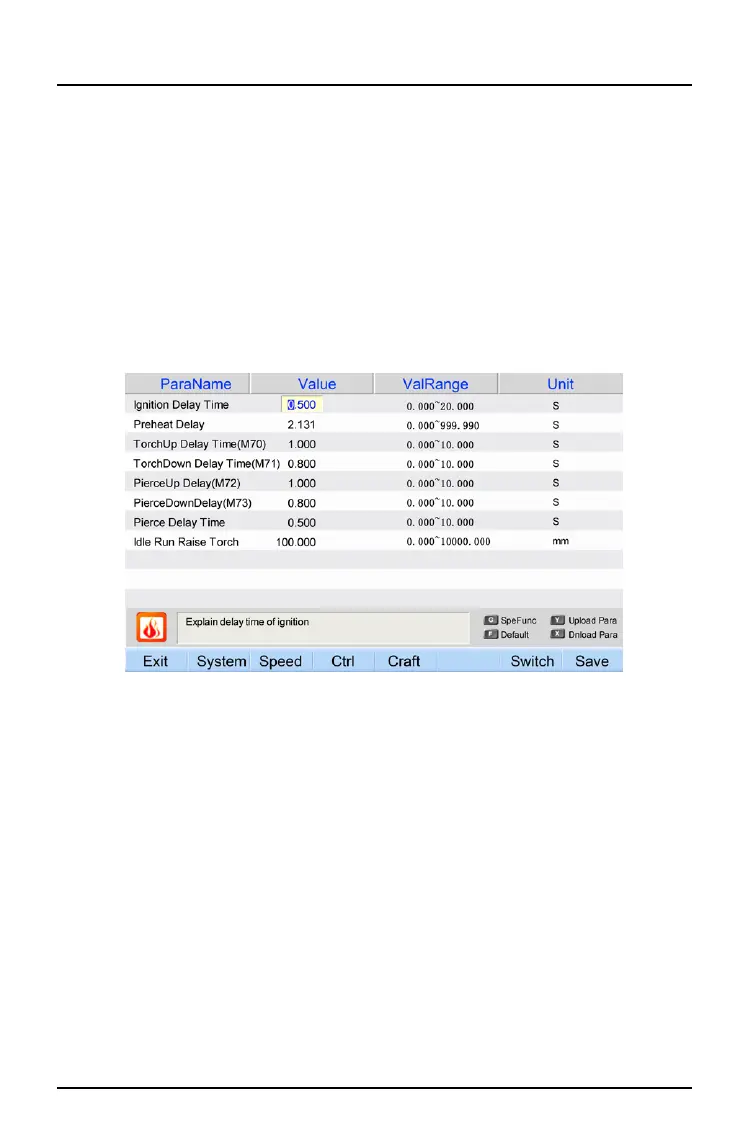

5.4.1.1 Ignition Delay Time: flame cutting, when M20, open high pressure ignition switch

delay time

5.4.1.2 Preheat Delay Time: pierce preheat time, unit: s, cut workpiece every time, preheat

delay time is 100s, if preheat is ok, can press [Start] to end preheat, and automatically save

preheat time parameter, after start to preheat, if preheat time is not enough, can press

[Pause] to add 100s to preheat

5.4.1.3 TorchUp Delay Time (M70): torch up delay time; unit: s

5.4.1.4 TorchDown Delay Time (M71): torch down delay time; unit: s

5.4.1.5 PierceUp Delay (M72) (pierce torch up delay time): unit: s

5.4.1.6 PierceDownDelay(M73): pierce torch down delay time, unit: s

5.4.1.7 Pierce Delay Time: flame cutting pierce M07, open cutting oxygen then torch down

5.4.1.8 Idle Run Raise Torch: idle run distance, unit: mm

5.4.1.9 Climb option: cut thick plate to avoid splashing steel slag after pierce, It is available

that after pierce torch cut and down instead of directly down from the pierce height to

cutting height.

(2) Plasma parameters

choose 0 to cancel hardware limit input to avoid unnecessary hardware fault

5.3.10 Collision Detection (torch collision detection): if equipment has torch collision

detection (P1 uses + limit input), choose 1, the input is normally closed, if torch collision (off),

stop (alarm).

5.3.11: Torch Up after Pause: if need torch to move up after pause, choose 1

5.3.12 Smooth Optimization: optimize program to avoid machine shaking caused by

frequent up and down, arc fit for small section, 1~3 level option, 0 NO. This function is

mainly used for figure files made by non-conventional CAD software, most are art figures or

letters, smooth optimization affect cutting, please choose this function according to need.

5.4 Enter Craft interface

(1) Flame parameters

Loading...

Loading...