Technical Information

23

PW 6xx7

converter electronic module, EFU 235, which in turn controls and

regulates the drive motor.

The procedures required to complete a wash cycle are collected in a

complete program. The control unit can save up to 199 programs, each with 5

blocks in 999 program positions.

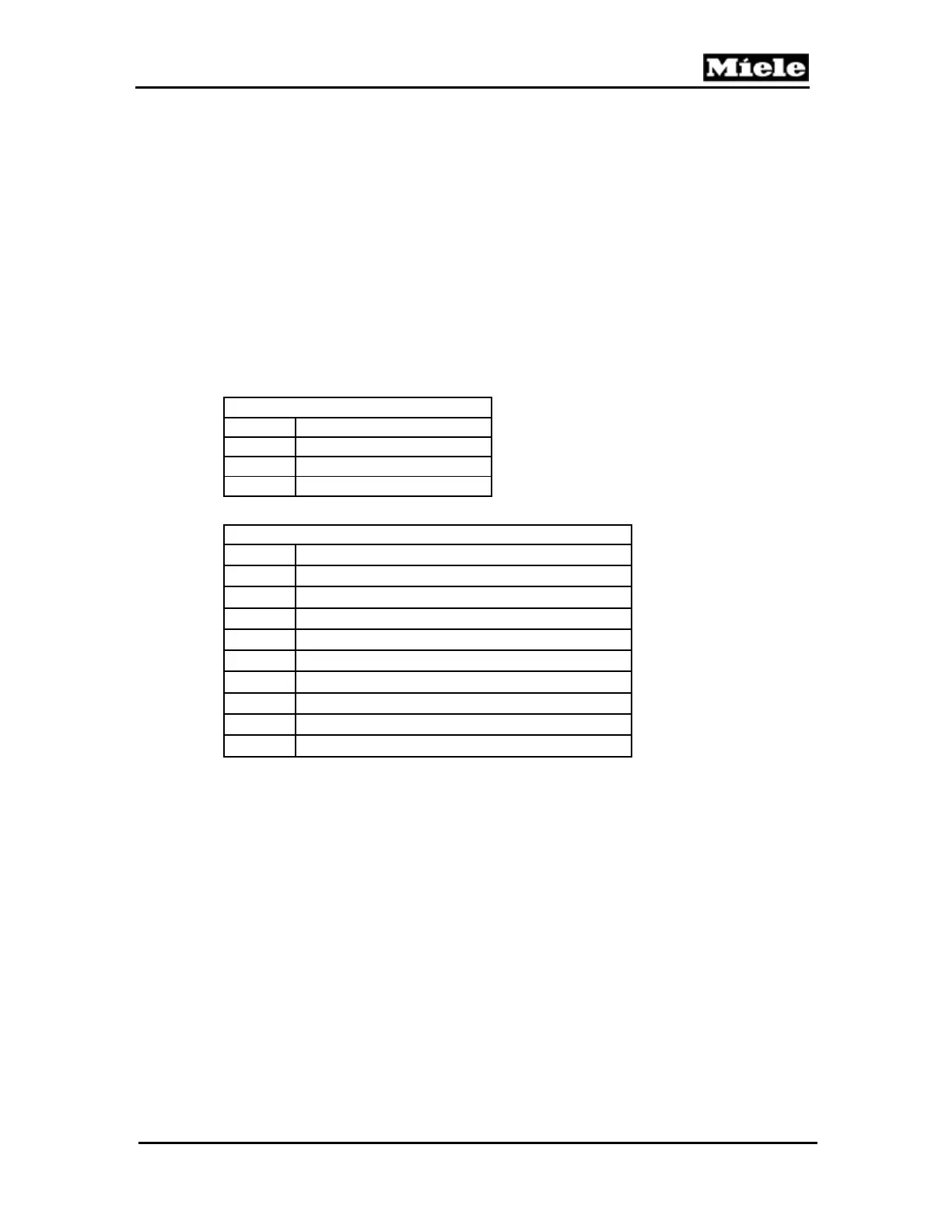

A program consists of a header and three program areas. See Table 100-4. A

program header has 19 separate divisions which define and fix general

program points; see the next section. Each of the three program areas

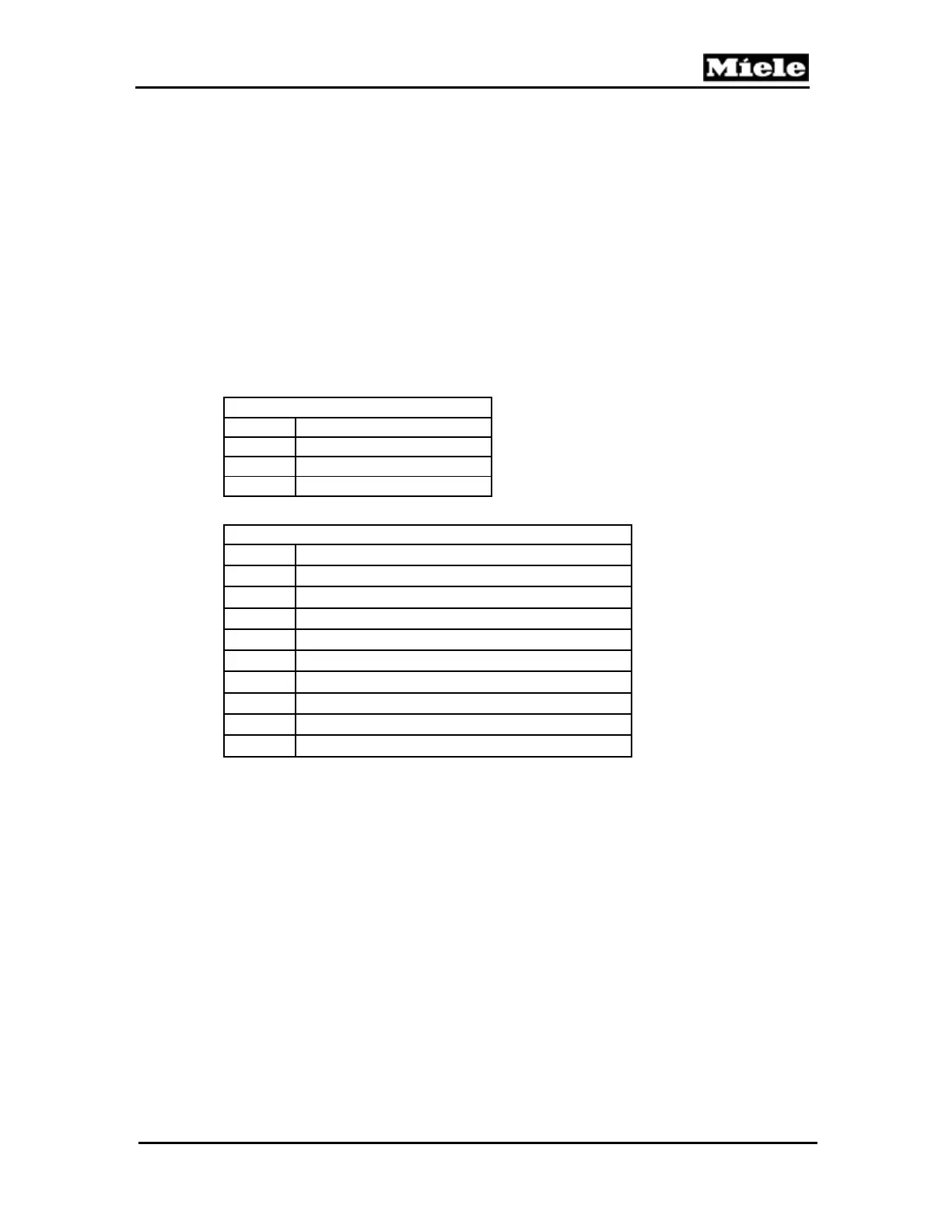

consists of a maximum of 10 program blocks. Each program block consists of

35 program steps and a field for the block name. The smallest practical

program has one area and one block (theoretically 0 areas with 0 blocks are

possible). The most complex program can have 3 areas each with 10 blocks.

See Table 100-5.

Wash program

Program header

Program area 1

Program area 2

Program area 3

Table 100-4: Basic Wash Program Structure

Program area 1

Program block 1

Program block 2

Program block 3

Program block 4

Program block 5

Program block 6

Program block 7

Program block 8

Program block 9

Program block 10

Table 100-5: Basic Program Area Structure

2.2 Wash Program Header

Structure and arrangement of program header: The program header

describes the general structure of a wash program and defines certain fixed

parameters.

Example 1: Should the heating be switched off during a program via the

Peak-load cutout input of the machine? See Table 100-6, Item 17, for

programming options: Yes or No.

Example 2: What is the charge for this program when using a payment

system? Answer: e.g. 1.25 currency units. See Table 100-6, Item 19.

Loading...

Loading...