Technical Information

57

PW 6xx7

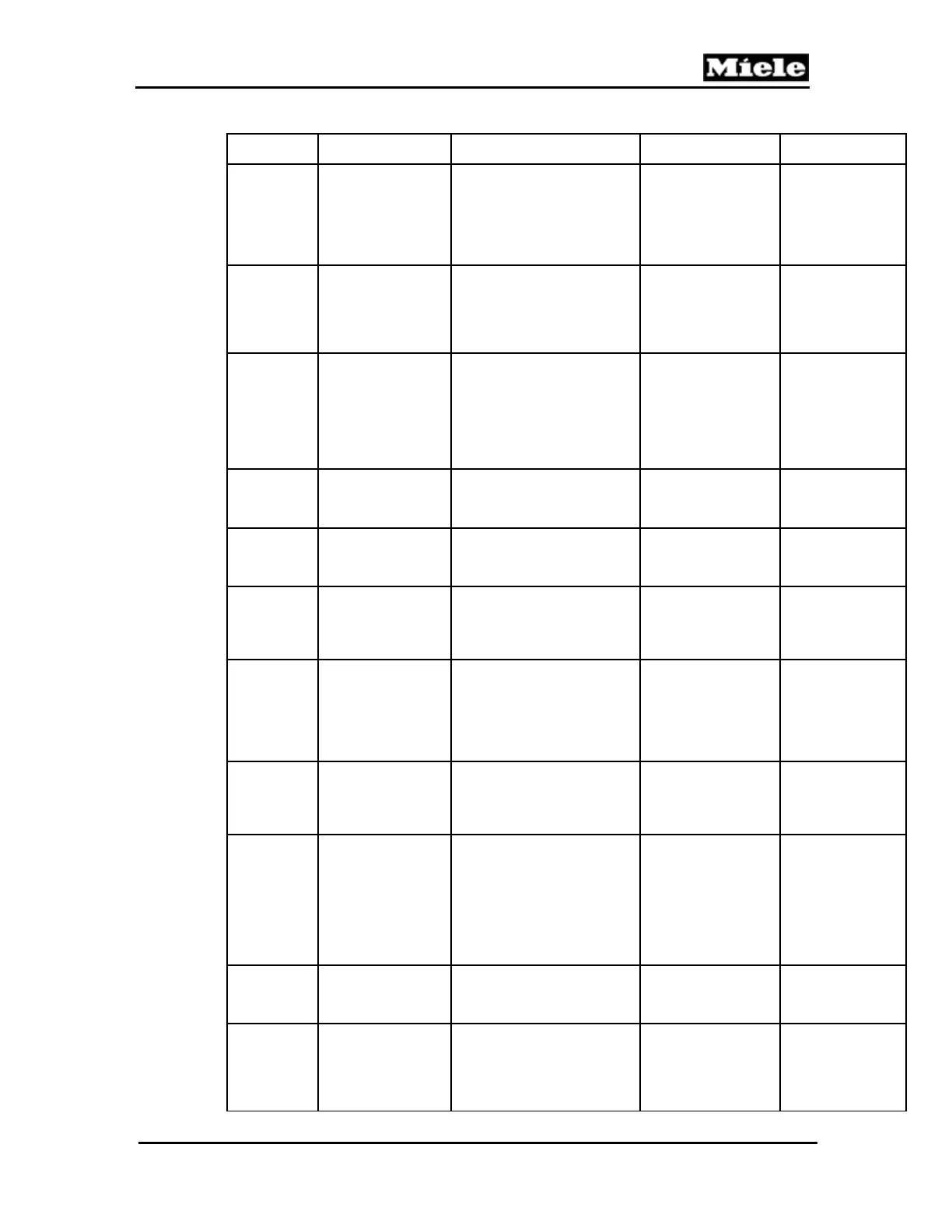

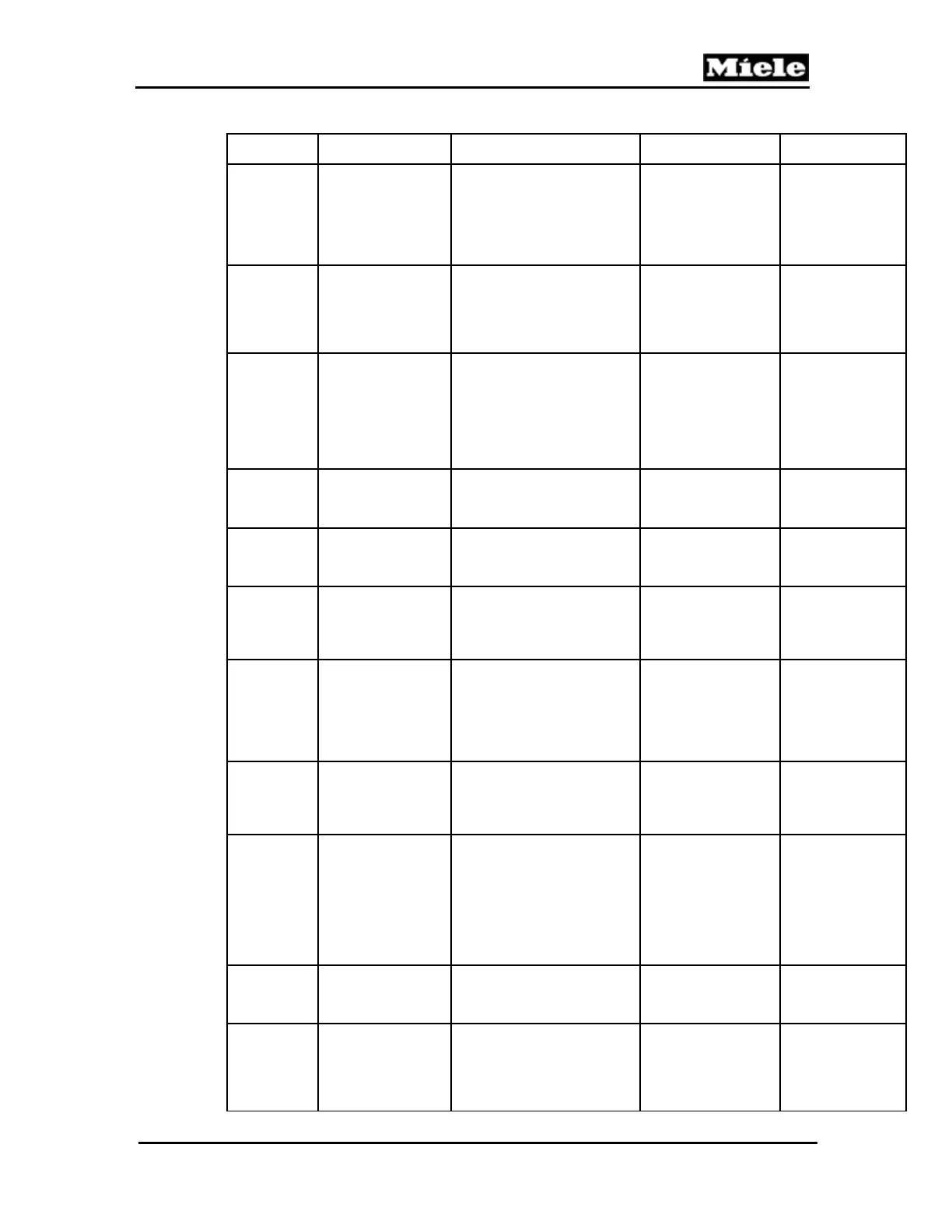

MDU fault # Possible cause Notes Indication in EW 235

display

Fault/Information

F4152 Switch 3S57 open-

circuited

Switch 3S57 is missing.

Check ELP 235 plug

N1L_ST24. Shutoff valve

closed. Check the drain valve

for soiling. Check for high water

consumption and long program

running times.

No display Fault

F4153 Analog pressure

sensor registers

overflow level or is

defective

Level has risen above target

level. Inlet valve jammed and

cannot be closed. Fault indica-

tion if overflow level set by

software is exceeded. Or ana-

log pressure sensor defective.

“WATER INLET

FAULT! Call the

service department if

restart does not work.”

Fault

F4154 Fault - Water

drainage

5 min after activation of “open

drain valve” signal, target level

has not been reached. Check

drain and its vent. Check valve

1Y26. Or drain valve concertina

hose crushed due to movement

of suds container or vacuum in

drain.

“DRAIN VALVE

FAULT! Call service

department if restart

does not work.”

Fault

F4155 Fault - Drainage

during spinning

Control interrupts spinning

when, during spinning, an

increase in water level of ≥ 50

mm wc is registered

“DRAIN VALVE

FAULT! Call service

department if restart

does not work.”

Fault

F4159 Fault - Dispenser

system

Dispenser container X empty. “DISPENSING

SYSTEM FAULT! Fill

dispenser X. Press the

start button.”

Fault

F4160 From ID 2286: Bridge

on dispenser module

(plug N1Q_ST14

GND-IN 7 defective).

From ID 2286: Shorting bridge

on plug N1Q_ST14 on

dispenser module defective.

“DISPENSER

RINSING FAULT! Call

the service department

if restart does not

work.”

Fault

F4161 Maintenance interval

for bearing greasing

exceeded

On washing machines with a

load rating greater than 13 kg,

bearings must be greased every

1000 operating hours. After

greasing has been carried out,

greasing counter must be reset

in service mode.

“BEARING

GREASING! Call the

service department.”

Fault

F4162 Maintenance interval

for service exceeded

Programmed interval for service

work has been exceeded. After

servicing is done, servicing

counter must be reset in service

mode.

“SERVICE INTERVAL!

Call the service

department.”

Fault

F4163 Maintenance interval

for testing in

accordance with

German accident

prevention legislation

guidelines exceeded

The programmed interval (1

year) for regular safety testing

(in Germany in accordance with

accident prevention legislation

guidelines) has been exceeded.

After testing has been carried

out, the appropriate counter

must be reset in the service

mode.

“BGR TESTING! Call

the service

department.”

Fault

F4164 Analog pressure

sensor on ELP 235

defective

Output signal of analog

pressure sensor on ELP 235

outside of permitted range.

“PRESSURE SENSOR

FAULT! Call service

department if restart

does not work.”

Fault

F4165 Open circuit between

plug EB 230 65X and

ELP 235 N1L_ST22.

Or EB 230 defective.

3 attempts by control to

calibrate loading module have

been unsuccessful. No zero

point setting possible. Plug

connection between EB 230

and ELP 235 defective.

“WEIGHING SYSTEM

FAULT! Call the

service department if

restart does not work.”

Fault

Loading...

Loading...