OM-253893 Page 22

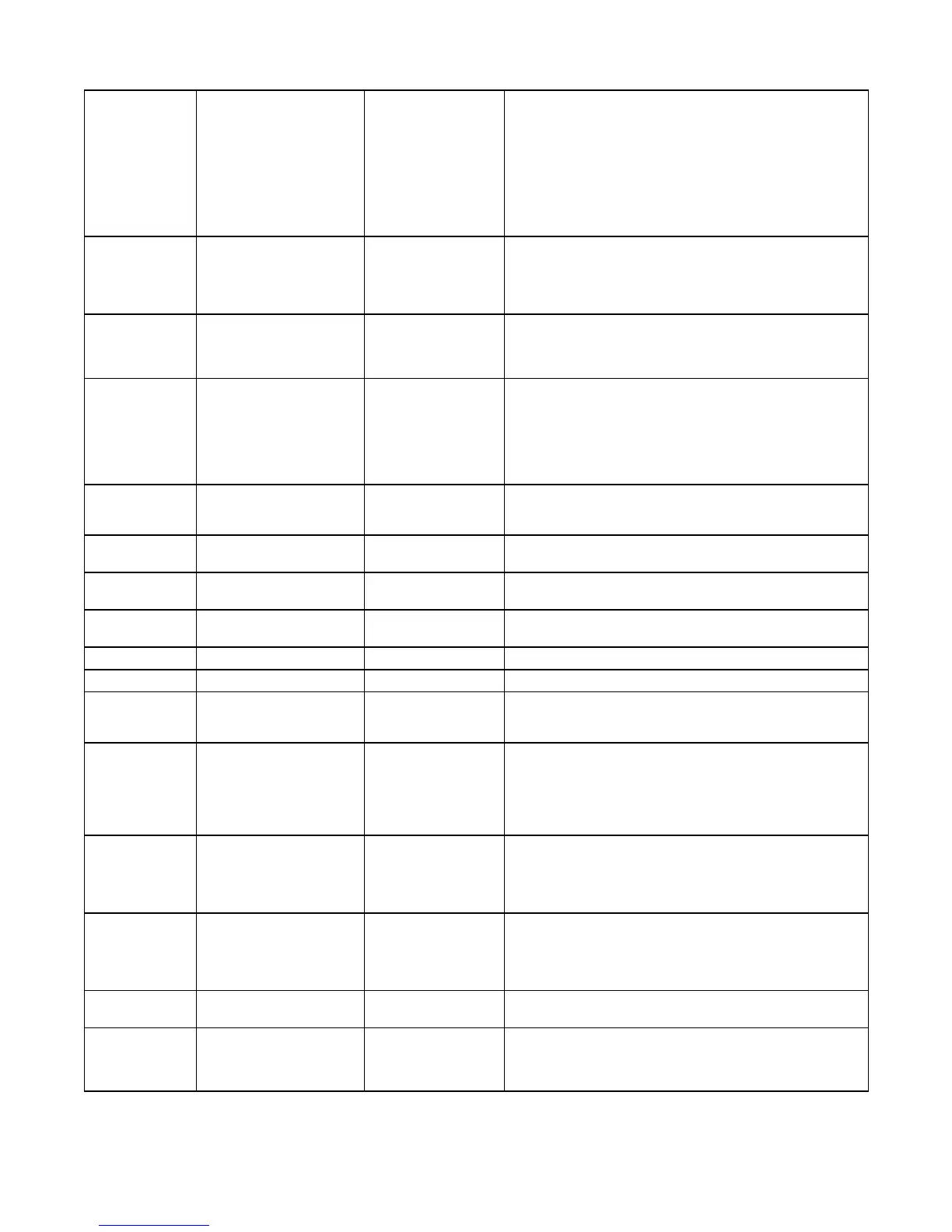

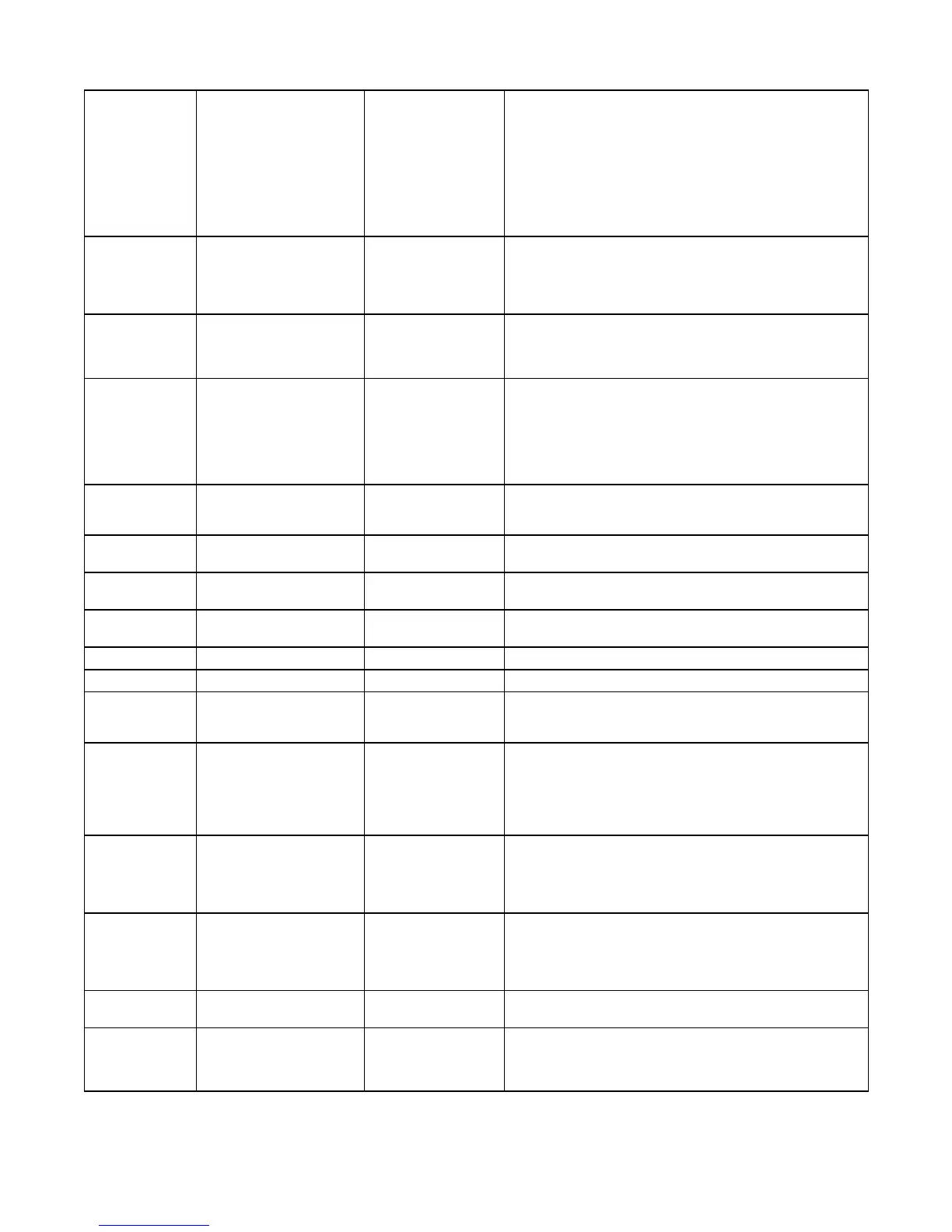

7-2. SubArc System Help Codes (Continued)

SubArc Interface

Digital Help Code

HELP will dis-

play in the up-

per display,

and the code

number will

display in the

lower display.

SubArc Power Source Sta-

tus/Trouble Light

Each flash sequence will

be followed by a one sec-

ond pause. The se-

quence will then repeat.

Fault Description

40 4 Quick Tach Error Indicates tach error on motor. Check wire feed drive housing and

wire spool for obstructions. Make sure motor cable is not routed

with weld cable (If inching works properly, noise may be corrupt-

ing the tach signal). If this code continues to appear on the dis-

play, contact the nearest Factory Authorized Service Agent.

42 4 Quick, 2 Slow Motor Error Indicates motor overcurrent error on motor. Check wire feed

drive housing and wire spool for obstructions. If this code contin-

ues to appear on the display, contact the nearest Factory Autho-

rized Service Agent.

44 4 Quick, 4 Slow Motor Low Bus Indicates bus voltage in SubArc Interface is low. 24 VAC from

power source may be low if input primary line voltage is too low

or, for DC power sources, power source could be incorrectly

linked. Increase primary line voltage to at least 90% of specified

nominal voltage. Check for correct linking on DC power sources.

If this code continues to appear, contact nearest Factory Autho-

rized Service Agent.

45 4 Quick, 5 Slow Button Stuck On Sys-

tem Interface Digital

Display Board

Indicates button is stuck on the digital interface upon power up.

Fault will clear when button is released.

48 4 Quick, 8 Slow Trigger Fault Indicates an arc was not established with the specified time

(lesser of 8 seconds or 4 inches).

56 5 Quick, 6 Slow Modbus Control Fault Indicates PLC is enabling weld output, flux, or wire jog on initial

communication. Clear all control bits of MODBUS 101 to reset.

60 6 Quick Memory Card Fault Indicates unable to read memory card. Faulty memory card or

wrong format.

61 6 Quick, 1 Slow File Read Error Indicates faulty file on memory card.

62 6 Quick, 2 Slow File Write Error Indicates full or faulty memory card.

63 6 Quick, 3 Slow Invalid File Indicates an invalid file on memory card. The system was able to

read the file; however, the contents of the file were invalid. Re-

move card or press any button to clear error.

64 6 Quick, 4 Slow Memory Card Locked Indicates a save was attempted to a locked card. This refers to

the physical switch on the memory card. Unlock the memory

card and try again. Try a different memory card. Remove card or

press any button to clear error. If this code continues to appear

on the display, contact the nearest Factory Authorized Service

Agent.

65 6 Quick, 5 Slow Read Only File Indicates a save was attempted to a file that has been marked

read−only. Check with the appropriate person to see if the at-

tributes are read only for a reason (the attributes can be altered

using a PC). Use a different card. Remove card or press any

button to clear error.

66 6 Quick, 6 Slow No Memory Card De-

tected

Indicates no memory card detected when a memory card opera-

tion was attempted. Insert a card or press any button to clear

error. Try a different memory card. If this code continues to ap-

pear on the display, contact the nearest Factory Authorized Ser-

vice Agent.

67 6 Quick, 7 Slow Unsupported Memory

Card Format

Indicates the file system is not supported. Memory card side is

too small.

71 7 Quick, 1 Slow Invalid Model Type If paralleling units, firmware in controlling power source does not

match firmware in the following power source. Update firmware

in both machines to the latest revision. If code continues to dis-

play, contact nearest Factory Authorized Service Agent.

Loading...

Loading...