105

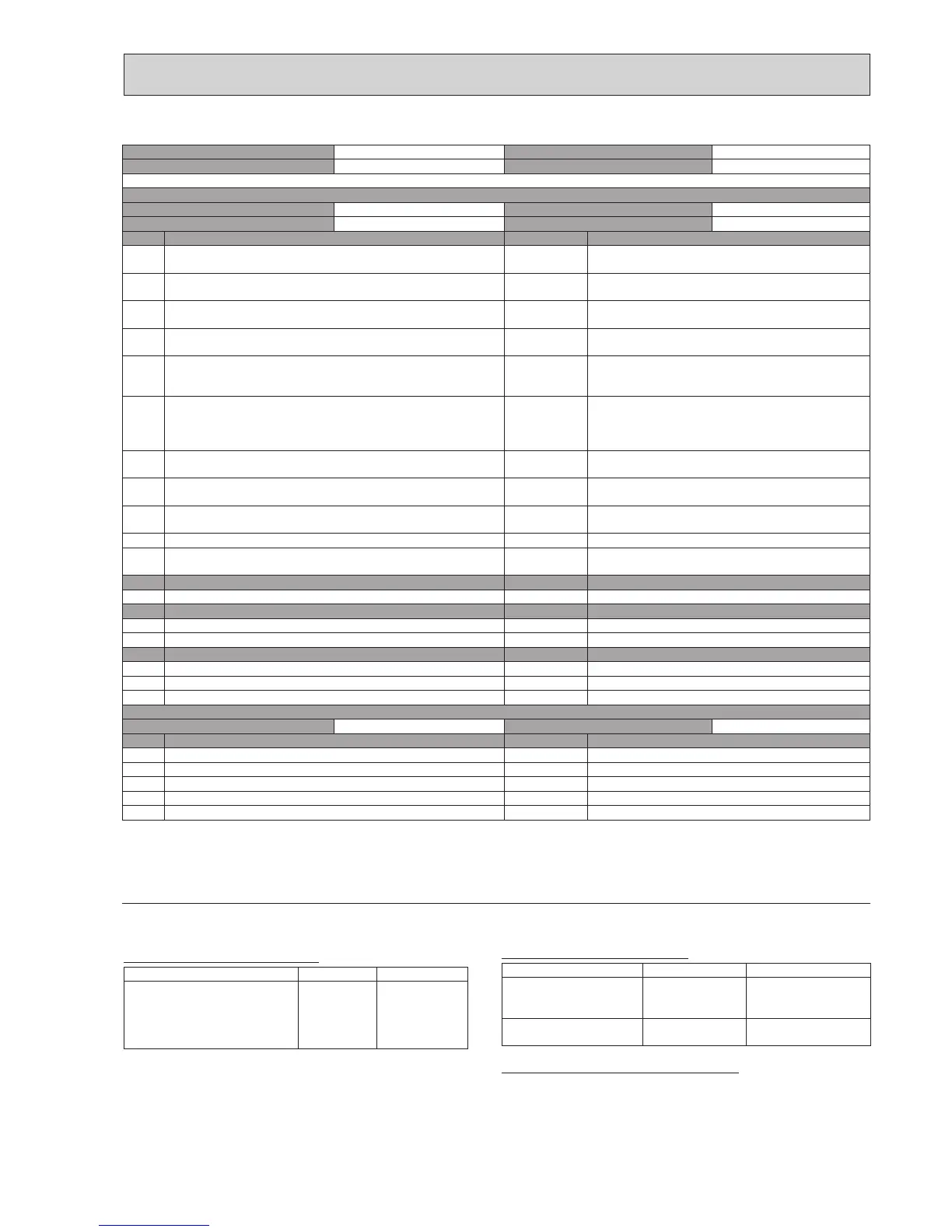

Annual Maintenance Log Book

Contractor name Engineername

Site name Site number

Cylinder unit maintenance record sheet

Warranty number Model number

Serial number

No. Mechanical Frequency Notes

1

TurnOFFwatersupply,drainDHWtank,removemeshfromstrainer

clean and replace in strainer. *1

2

KeepwatersupplyOFF,openhotwatertapsandchecktheprimary-side

expansionvesselchargepressure.Topupifnecessary(1bar).

3

KeepwatersupplyOFFandcheckthepotablevesselchargepressure.

Top up if necessary (3.5 bar).

4

KeepwatersupplyOFF.Inhardwaterareasde-scalingoftheimmersion

heaters may be required.

5

Droptheprimary/heatingsystempressuretozerocheckandifneces-

sarytopuptheexpansionvessel(1bar).Airvalveofexpansionvesselis

TR-412.

6

TurnwatersupplyON,openthepressurereliefvalveandthentheexpan-

sionreliefvalveinturn.Checkforunrestricteddischargetothetundish

andthatthevalvesreseatcorrectly.Checktherearenoblockagesinthe

tundishandassociatedpipework.

7

Checkandifnecessarytopuptheconcentrationofanti-freeze/inhibitor(if

used in the system).

8

Topuptheprimary/heatingsystemusingatemporarybackowpreven-

tionllingloopandre-pressuriseto1bar.

9

Heatsystemandcheckpressuredoesnotriseabove3barandnowater

is released from the safety valves.

10 Release any air from the system.

11

Tocheckthe3-wayvalveforinsideleaks,conrmthatthetemperatureof

theheatemitterdoesnotrisewhenrunningtheDHWmode.

Refrigerantmodelsonly[exceptEHPT20series] Frequency Notes

1 Refer to outdoor unit manual.

Electrical Frequency Notes

1 Check condition of cables.

2 Checkratingandfusettedontheelectricitysupply.

Controller Frequency Notes

1 Checkeldsettingsagainstfactoryrecommendations.

2 Checkoperationofmotorizedvalvesensuretheyreseatcorrectly.

3 Checkbatterypowerofwirelessthermostatandreplaceifnecessary.

Outdoor heat pump unit maintenance record sheet

Model number Serial number

Mechanical Frequency Notes

1 Inspectgrillandairinletfortrappeddebris/damage.

2 Check condensate drain provision.

3 Checkintegrityofwaterpipeworkandinsulation.

4 Check all electrical connections.

5 Checkandrecordtheoperationvoltage.

* Checks should be carried out once a year.

*1Besuretoreattachthemeshafterwashing.

Note:Withintherstcoupleofmonthsofinstallation,removeandcleanthecylinderunit’sstrainermeshplusanythatarettedexternaltothecylinder

unit. This is especially important when installing on an existing system.

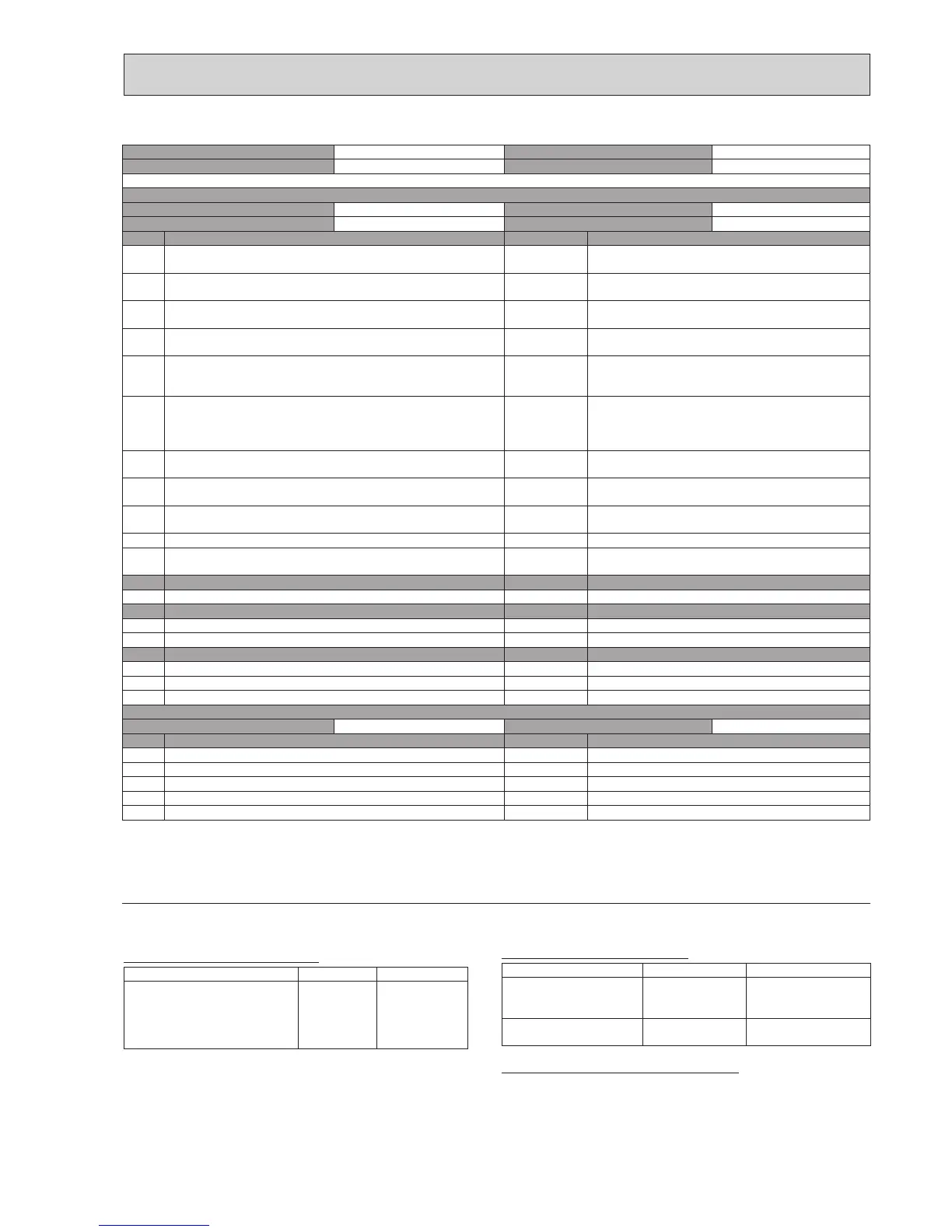

Inadditiontoannualservicing,itisnecessarytoreplaceorinspectsomepartsafteracertainperiodofsystemoperation.Pleaseseetablesbelowfordetailedinstruc-

tions.Replacementandinspectionofpartsshouldalwaysbedonebyacompetentpersonwithrelevanttrainingandqualications.

Parts which require regular replacement

Parts Replace every Possible failures

Pressure relief valve (PRV)

Air vent (Auto/Manual)

Drain cock (Primary/Sanitary circuit)

Manometer

Inletcontrolgroup(ICG)*

6 years Waterleakage

*

OPTIONAL PARTS for UK

Parts which require regular inspection

Parts Check every Possible failures

Immersion heater 2 years

Earthleakagecausing

circuit breaker to activate

(HeaterisalwaysOFF)

Water circulation pump 20,000 hrs (3 years)

Water circulation pump

failure

Parts which must NOT be reused when servicing

*O-ring

* Gasket

Note: Always replace the gasket for pump with a new one at each regular

maintenance (every 20,000 hours of use or every 3 years).

Loading...

Loading...