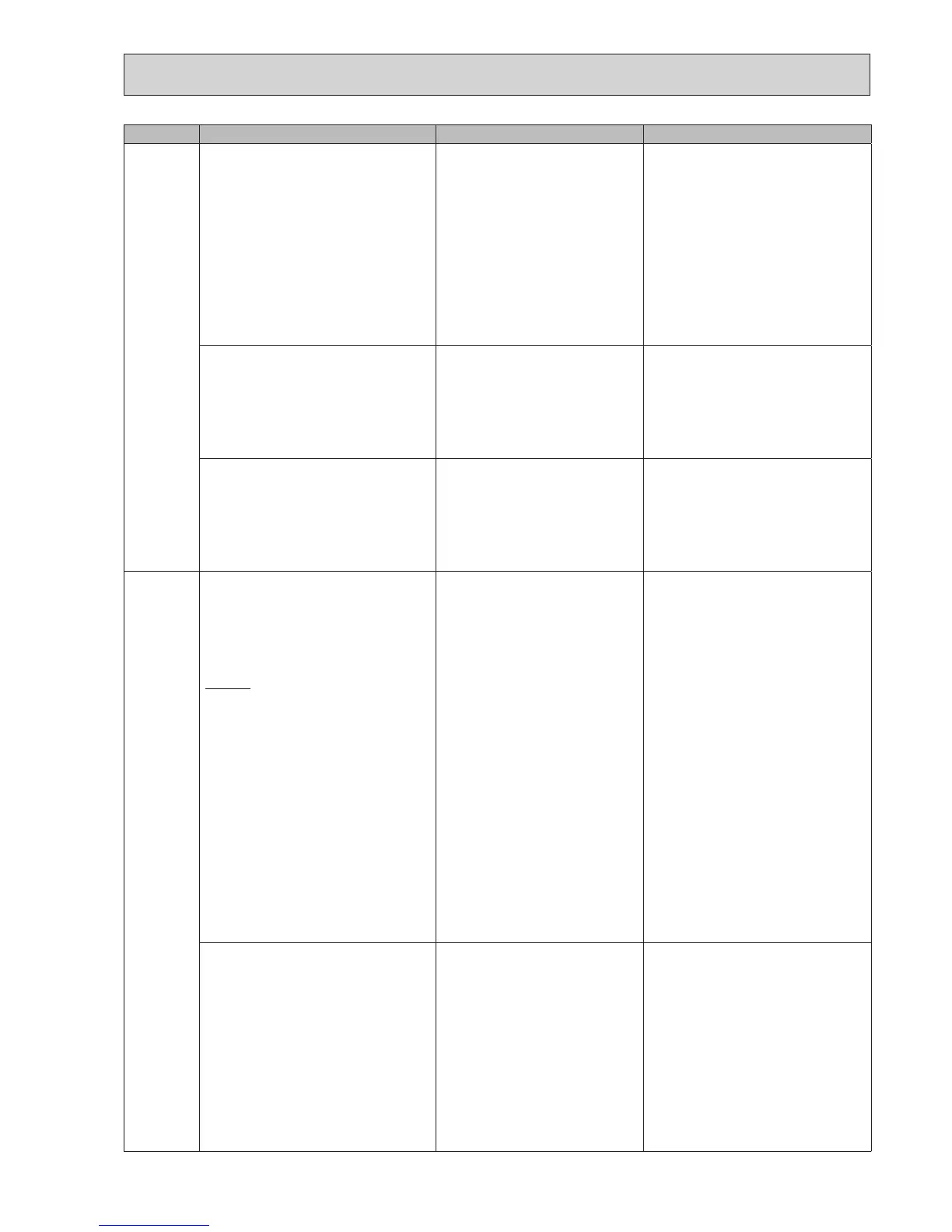

65

Error code Title and display conditions Possible Cause Diagnosis and action

L8 Heating operation error

Note: “3” is displayed in “Request code: 567” in

“Runninginformation”.

<Heating/FS>

If a), b) and c) occur, L8 is displayed;

a)

NochangeonTHW1andTHW5

(under1°Cfor20minutesfromunitstarts

operation)

b)

NochangeonTHW1

(under1°Cfor10minutesfromboosterheater

starts operation)

c)

THW1−THW2<−5°C

(for 10 minutes continuously)

1. THW1 has become detached from its

holder.

1. Visually inspect location and reattach as

necessary.

2. Booster heater fault 2. Electrically test to determine fault.

See"10-6.CheckingComponentParts'

Function"forhowtocheck.

3. THW1 or THW2 or THW5 fault 3. Checkresistanceofthermistoragainst

tablein"10-6.CheckingComponentParts'

Function".

Compare FTC detected temperature to

hand held detector.

4. FTC board failure 4. Replace board.

Heating operation error

Note:

“A” is displayed in “Request code: 567” in

“Runninginformation”.

1. THW6 has become detached from its

holder.

1. Visually inspect location and reattach as

necessary.

2. THW6 or THW7 fault 2. Checkresistanceofthermistoragainst

tablein"10-6.CheckingComponentParts'

Function".

Compare FTC detected temperature to

hand held detector.

3. FTC board failure 3. Replace board.

Heating operation error

Note: “C” is displayed in “Request code: 567” in

“Runninginformation”.

1. THW8 has become detached from its

holder.

1. Visually inspect location and reattach as

necessary.

2. THW8 or THW9 fault 2. Checkresistanceofthermistoragainst

tablein"10-6.CheckingComponentParts'

Function"

Compare FTC detected temperature to

hand held detector.

3. FTC board failure 3. Replace board.

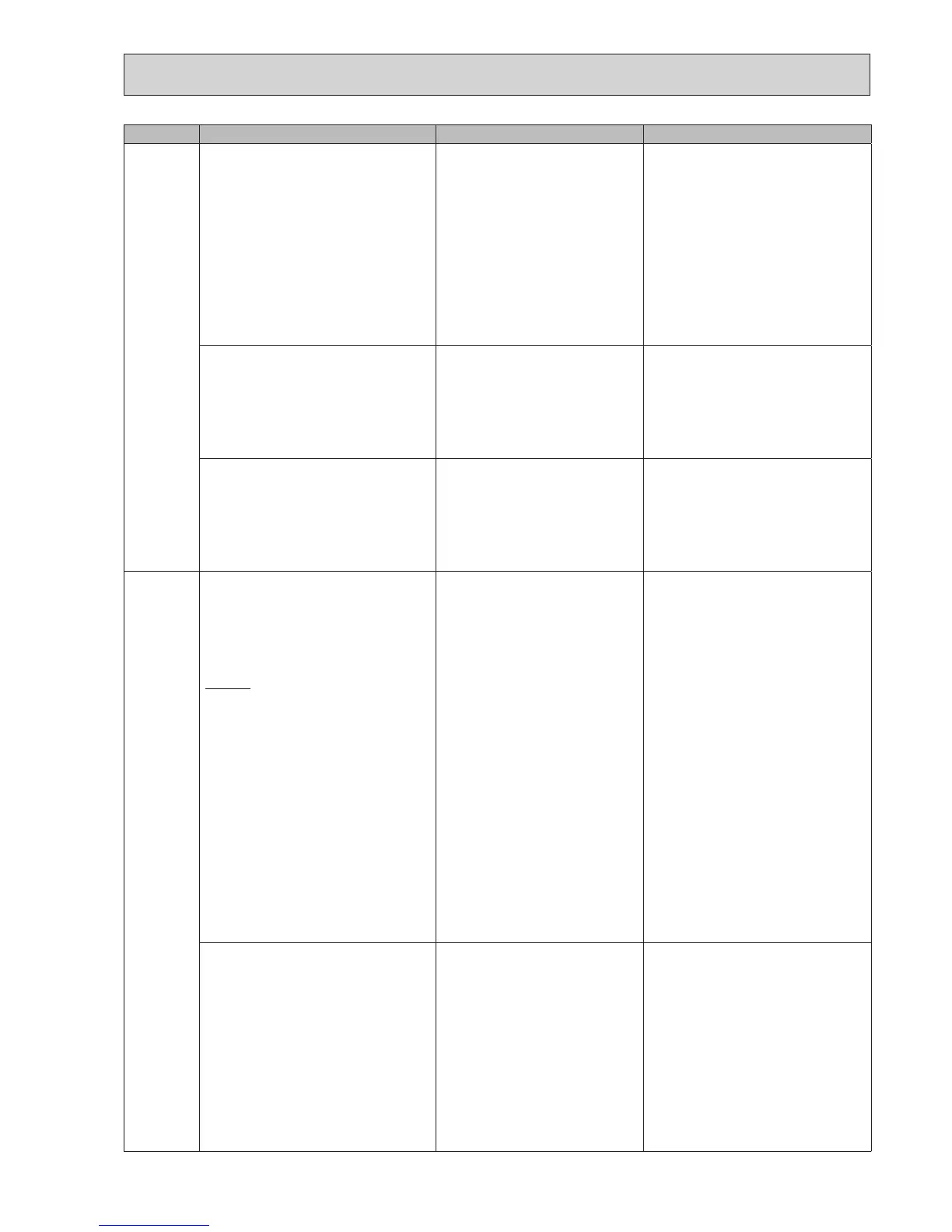

L9

Lowprimarycircuit(Heatsourceside)ow

ratedetectedbyowsensor

Note: “1” is displayed in “Request code: 569” in

“Runninginformation”.

<DHW/Heating/LP/FS>

Errorcodedisplayedwhenowsensordetects

lowowratefor10seconds.

Exception

For1minuteafterwatercirculationpump1is

switchedon.

1. Insufcientsystemhead 1. Refertotablein"10-6.CheckingCom-

ponentParts'Function"todetermineif

system pump meets requirements.

If more head required either add a pump

ofthesamesizeorreplaceexistingpump

withcapacitymodel.

See"11.DISASSEMBLYPROCEDURE"

forhowtoreplacepump.

2. Reducedowinprimarywatercircuit

Dueto1ormoreofthefollowing;

Faultypump,insufcientairpurge,

blockedstrainer,leakinwatercircuit.

2. Checkcirculationpump(See"10-6.Check-

ingComponentParts'Function"forhowto

check).

Openpurgevalvetoremovetrappedair.

Checkthestrainerforblockages.

Checktheprimarywatercircuitforleaks.

Checkthattheowamountiswithinthe

recommendedrange.

3. Valve operation fault 3. Checkvalvesonprimarywatercircuitare

installed level.

4.

2-wayvalve(localsupply)actuator

fault

4. Electrically test to determine fault.

5. Connector/terminalwirehasbecome

detachedorloosewiring.

5. Visually check the CN1A connector and

IN2 terminal and reattach if necessary.

6. Flowsensorfault 6. Electrically test to determine fault.

See"10-6.CheckingComponentParts'

Function"forhowtocheck.

7. IncorrectsettingoftheSW2-2 7. ChecktheSW2-2setting.

8. FTC board failure 8. Replace board.

Lowprimarycircuit(Zone1side)owrate

detectedbyowswitch

Note: “2” is displayed in “Request code: 569” in

“Runninginformation”.

1. Insufcientsystemhead 1. If more head required either add a pump of

thesamesizeorreplaceexistingpump.

2. Reducedowinprimarywatercircuit

Dueto1ormoreofthefollowing;

Faultypump,insufcientairpurge,

blockedstrainer,leakinwatercircuit.

2. Checkcirculationpump(See"10-6.Check-

ingComponentParts'Function"forhowto

check).

Openpurgevalvetoremovetrappedair.

Checkthestrainerforblockages.

Checktheprimarywatercircuitforleaks.

Checkthattheowamountiswithinthe

recommendedrange.

3. Terminalwirehasbecomedetached

orloosewiring.

3. Visually check the IN3 terminal and reat-

tach if necessary.

4. Flowswitchfault 4. Electrically test to determine fault.

5. IncorrectsettingoftheSW3-2 5. ChecktheSW3-2setting.

6. FTC board failure 6. Replace board.

Loading...

Loading...