70

No. Fault symptom Possible cause Explanation - Solution

4 LED2 on FTC is off.

(See"6.WIRING

DIAGRAM".)

<FTCpoweredonindependentsource>

1. FTCisnotsuppliedwith220to240VAC. 1. CheckthevoltageacrosstheLandNterminalsontheindoorpowersupply

terminalblock.(See"7.FIELDWIRING".)

•Whenthevoltageisnot220to240VAC,checkforfaultywiringtopower

supply.

•Whenthevoltageis220to240VAC,goto2.below.

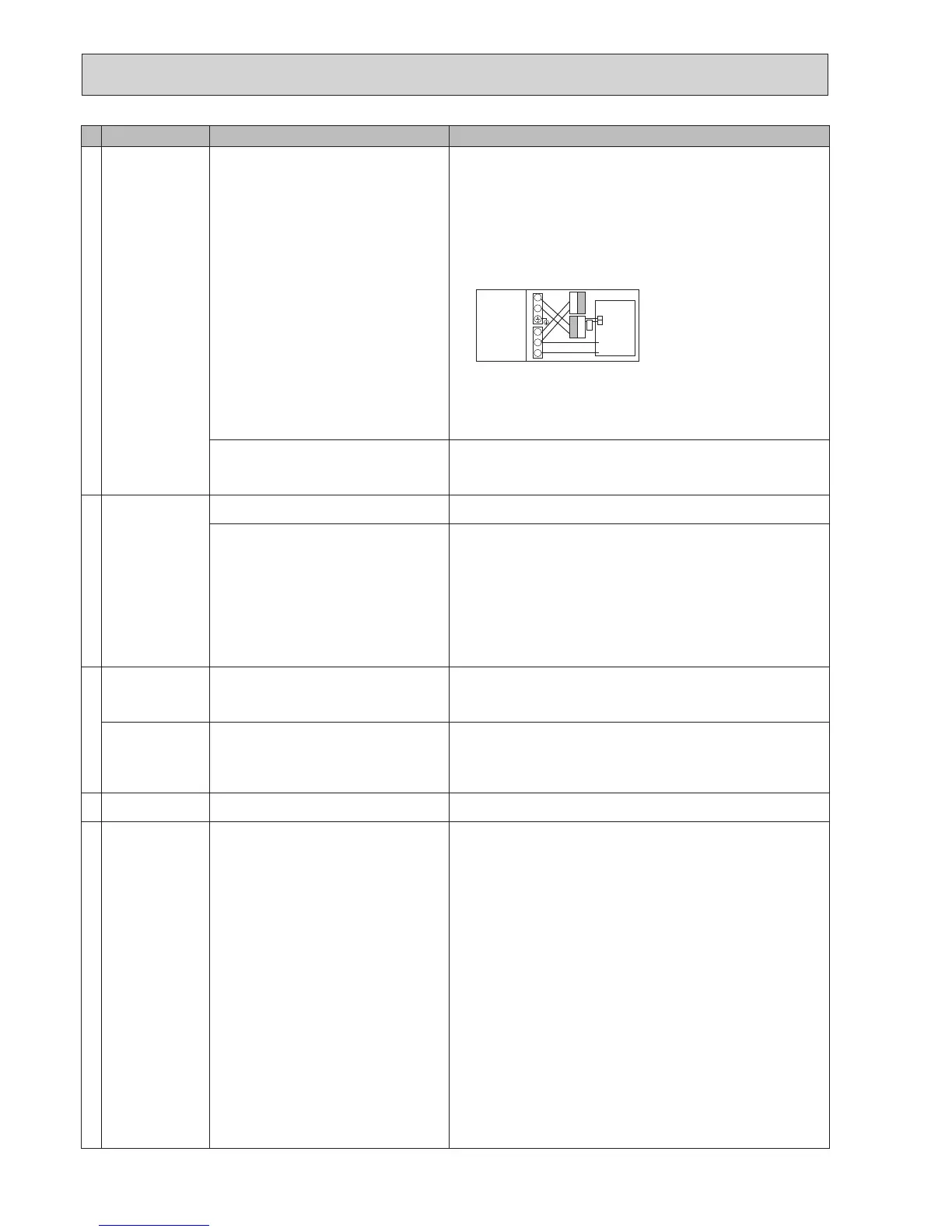

2. There are problems in the method of

connectingtheconnectors.

2. Checkforfaultywiringbetweentheconnectors.

•Whentheconnectorsarewiredincorrectlyre-wirethem correctlyreferring

tobelow.(See"7.FIELDWIRING"andawiringdiagramonthecontroland

electricalboxcover.)

L

N

CN01

CN01

S1

S2

S3

•Ifnoproblemfoundwiththewiring,goto3.below.

3. FTC failure 3. Check the FTC control board.

•CheckthefuseonFTCcontrolboard.

•Checkforfaultywiring.

•Ifnoproblemfoundwiththewiring,theFTCcontrolboardisfaulty.

When LED1 on FTC is lit. Rechecktherefrigerantaddresssettingontheoutdoorunit.

Settherefrigerantaddressto“0”.

(SetrefrigerantaddressusingSW1(3-6)onoutdoorcontrollercircuitboard.)

Incorrectsettingofrefrigerantaddressfor

outdoor unit.

(Noneoftherefrigerantaddressissetto"0".)

5 LED2 on FTC is

blinking.

(See"6.WIRING

DIAGRAM".)

WhenLED1isalsoblinkingonFTC. CheckforfaultywiringbetweenFTCandoutdoorunit.

FaultywiringbetweenFTCandoutdoorunit

When LED1 on FTC is lit.

1. Faultywiringinmainremotecontroller

Multipleindoorunitshave been wired to a

singleoutdoorunit.

1. Checkforfaultywiringinmainremotecontroller.

Thenumberofindoorunitsthatcanbewiredtoasingleoutdoorunitisone.

Additionalindoorunitsmustbewiredindividuallytoasingleoutdoorunit.

2. Short-circuitedwiringinmainremotecontrol-

ler

2.,3.

Removemainremotecontroller wires and check LED2 on FTC.(See"6.

WIRINGDIAGRAM".)

•

IfLED2isblinkingcheckforshortcircuitsinthemainremotecontrollerwiring.

•IfLED2islit,wirethemainremotecontrolleragainand:

-ifLED2isblinking,themainremotecontrollerisfaulty;

-

ifLED2islit,faultywiringofthemainremotecontrollerhasbeencorrected.

3. Main remote controller failure

6 LED4 on FTC is off.

(See"6.WIRING

DIAGRAM".)

1. SD memory card is NOT inserted into the

memorycardslotwithcorrectorientation.

1. Correctly insert SD memory card in place until a click is heard.

2. Not an SD standards compliant memory card. 2. Use an SD standards compliant memory card. (Refer to installation manual,

"5.8UsingSDmemorycard".)

LED4 on FTC is

blinking.

(See"6.WIRING

DIAGRAM".)

1. Full of data. 1. Moveordeletedata,orreplaceSDmemorycardwithanewone.

2. Write-protected. 2. Releasethewrite-protectswitch.

3. NOT formatted. 3. Refertoinstallationmanual,"5.8UsingSDmemorycard".

4. FormattedinNTFSlesystem. 4. FTCis Notcompatible withNTFSlesystem.UseanSDmemorycardfor-

mattedinFATlesystem.

7 Nowaterathottap. 1. Cold main off 1. Check and open stop cock.

2. Strainer (local supply) blocked. 2. Isolatewatersupplyandcleanstrainer.

8 Coldwaterattap. 1. Hotwaterrunout. 1. EnsureDHWmodeisoperatingandwaitforDHWtanktore-heat.

2. Prohibit, schedule timer or holiday mode se-

lected or demand control input (IN4) or smart

gridready(switch-offcommand).

2. Checksettingsandchangeasappropriate.

3. Heatpumpnotworking. 3. Check heat pump – consult outdoor unit service manual.

4. Booster heater cut-out trip

ped

. 4. Check booster heater thermostat and press reset button if safe.

Resetbuttonislocatedonthesideofboosterheater,coveredwithwhiterub-

bercap.See"4.PARTNAMESANDFUNCTIONS"tondoutitsposition.

5.

Theearthleakagecircuitbreakerforbooster

heater breaker (ECB1) tripped.

5. Check the cause and reset if safe.

6. The booster heater thermal cut-out has

trippedandcannotberesetusingthemanual

reset button.

6. Check resistance across the thermal cut-out, if open then the connection is

brokenandtheboosterheaterwillhavetobereplaced.

Contact your Mitsubishi Electric dealer.

7. Immersion heater cut-out tripped. 7. Check immersion heater thermostat and press reset button, located on im-

mersionheaterboss,ifsafe.If the heater has been operated with no water

insideitmayhavefailed,sopleasereplaceitwithanewone.

8.

Immersion heater breaker (ECB2) tripped.

8. Check the cause and reset if safe.

9. 3-wayvalvefault 9. Checkplumbing/wiringto3-wayvalve.

(i)Manuallyoverride3-wayvalveusingthemainremotecontroller.(Referto

<Manualoperation>in"9-4.Servicemenu")Ifthevalvedoesnotstillfunc-

tion,goto(ii)below.

(ii)Replace3-wayvalvecoil.Ifthevalvedoesnotstillfunction,goto(iii)be-

low.

(iii)Replace3-wayvalve.(Referto"11.DISASSEMBLYPROCEDURE".)

YELLOW

YELLOW

BLACK

BLACK

Modiedsettings

(Separatepower

supply to the

cylinder unit)

Cylinder unit

control board

White

Loading...

Loading...