4.3 Adjustment of tension detector

4. Adjustment and Initial Setting

24

2) Span adjustment for tension detector

• The material tension (load detected by the tension detector) depends on the installation direction of

the detector or the material-threading angle. To correctly detect the material tension, correct the

span.

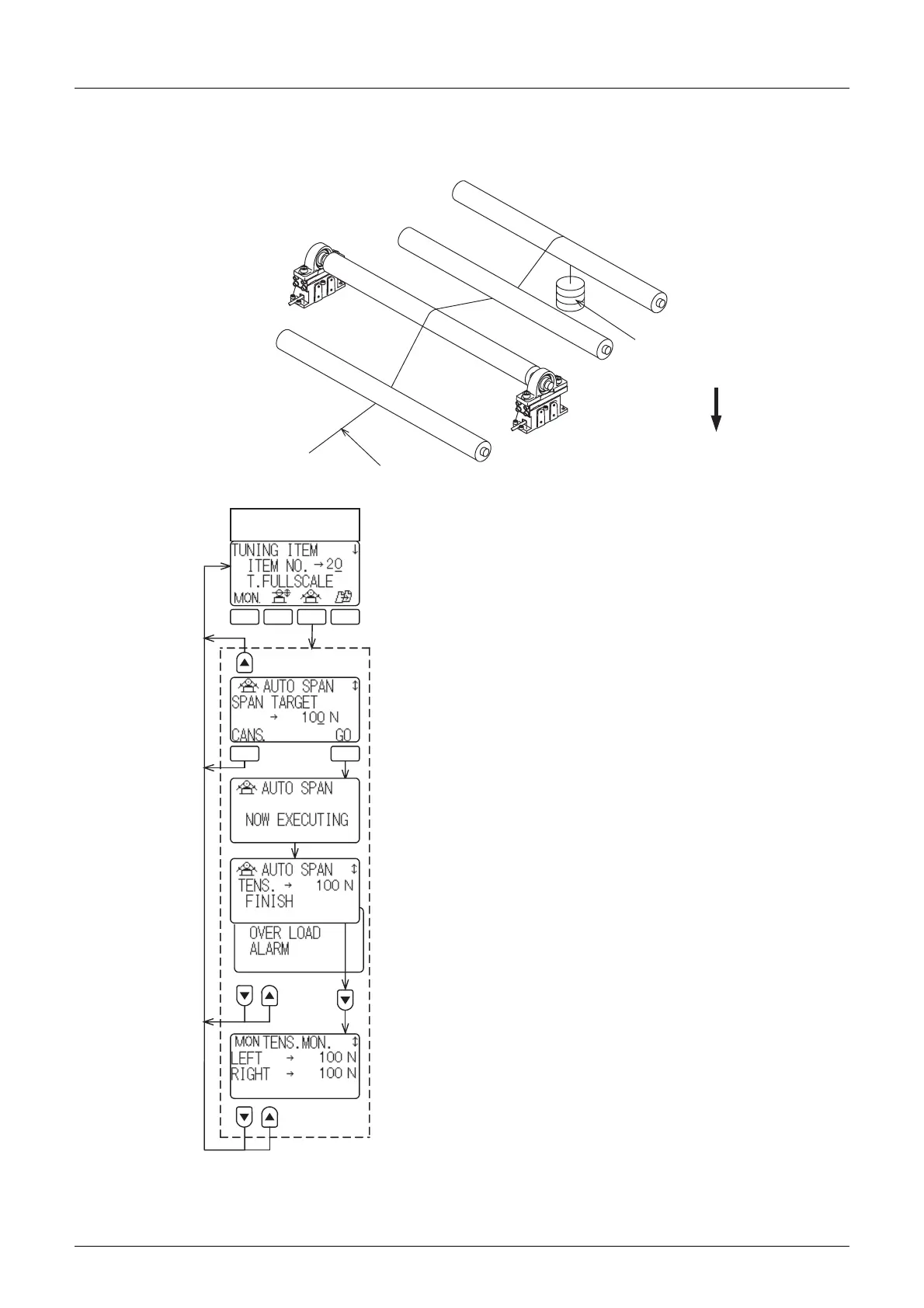

[1] Press the [F3] function key to move to the auto span adjustment

screen.

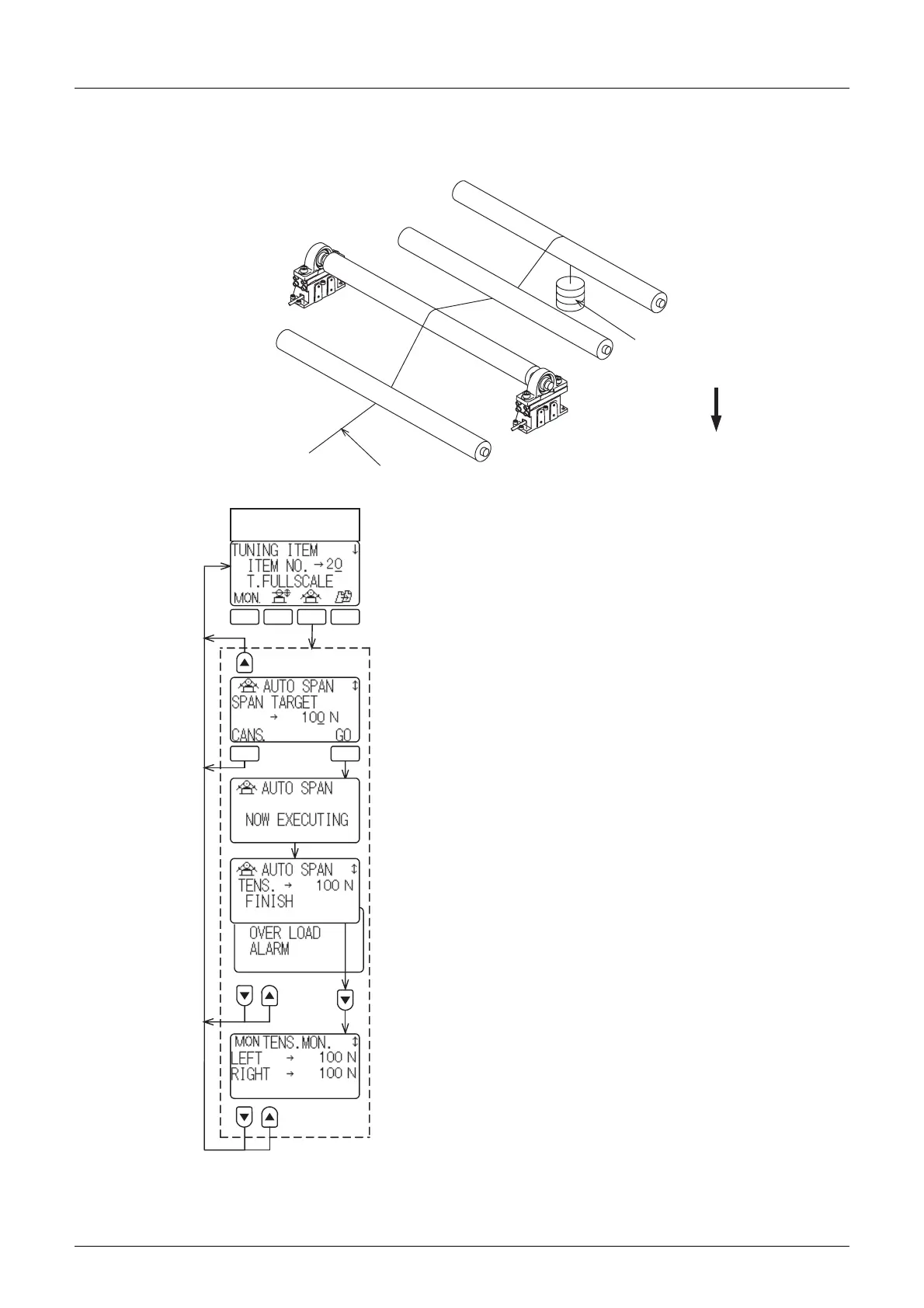

[2] Hang known weight W (N) from the detector roller. Apply a static

load close to the full-scale tension value. (The static load should be

in the range of 1/3 to 100% full-scale tension, and the full-scale

tension should be in the range of 20 to 80% of the rated load of the

tension detector.)

[3] Enter a numeric value equivalent to load W (N), and then press the

[GO] key.

(ex) If the weight hung from the roller is 10 kg, enter 98 (N)

- - - - - - - - -10 kg × 9.8 m/s

2

(gravitational acceleration).

If the applied weight is changed during adjustment, further

modification may not be possible, or an error may be caused.

[4] The message "NOW EXECUTING" will be displayed for

approximately 2 seconds.

[5] The message "FINISH" or an error message will appear. If an error

message appears, check the problem while referring to pages 46,

48.

Thread a string through the roller centers.

Hang known weight.

Load W (N)

(= Mass kg ×9.8 m/s

2

)

Target tension of span tuning

F1 F4

Auto span tuning

screen

F1 F2 F3 F4

Adjustment/setting

item selection screen

Loading...

Loading...