Programming via CANopen

network (Routing)

03/05 AWB2724-1453G

56

Alternatively, you can use the BlockSizeEditor application to

change the block size.

The download block size is defined in the following Registry key:

[HKEY_LOCAL_MACHINE\SOFTWARE\3S-Smart Software Solutions

GmbH\Gateway Server\Drivers\Standard\Settings\Tcp/Ip (Level 2

Route)]

"Blocksize"=dword:00020000

The default block size is 20000

hex

(=128 Kbyte), the block size for

routing is 1000

hex

(= 4 Kbyte).

Notes

• If large files are written to the target PLC or read from the PLC,

it is possible that the online connection will be interrupted after

the transfer process has been completed. Renewed connection

is possible.

• If a program with a modified routing node ID is loaded into the

target PLC, the target PLC accepts the modified routing node ID;

however, the communication connection will be interrupted.

Reconnection with a corrected routing node ID is possible.

• If a PLC receives a program without valid routing parameters

(baud rate/node ID), this PLC cannot be connected via a routing

connection.

• The routing is independent of the configuration (master/slave):

a target PLC that has not been configured as a master or as a

slave can be accessed. It must only receive the basic parameters

such as node ID and baud rate, as well as a simple program.

Addressing

PLCs on the CANopen bus can be configured as a master or as a

device. The PLCs are assigned with a Node ID/node number

(address) in order to uniquely identify them. If you wish to use the

routing function to access a (target) PLC, you must assign the

target PLC with a further (Routing) Node ID.

Procedure

X Connect the PC to a PLC.

X Select the target PLC with which you want to communicate for

the project.

X Determine the communication settings for the PC and the PLC

connected to the PC.

X Enter the target ID (target ID = Node ID!) of the target PLC as

in the example and log on.

You can run the following functions:

• Program download

• Online modification

• Program test (Debugging)

• Create bootable project

• Filing source code.

Note for project creation:

The node ID/node number and the baud rate of the target PLC to

the routing function can be defined in the Additional parame-

ters tab in the PLC Configuration window:

Enter the baud rate on the CANopen bus and the Node-ID/node

number in the “RS232 l CAN routing settings” field.

This field appears with the XC200, after you have confirmed it in

the Activate field. This activation is necessary to ensure that the

PLC can communicate via the CANopen bus.

Node ID and baud rate are transferred with the project download.

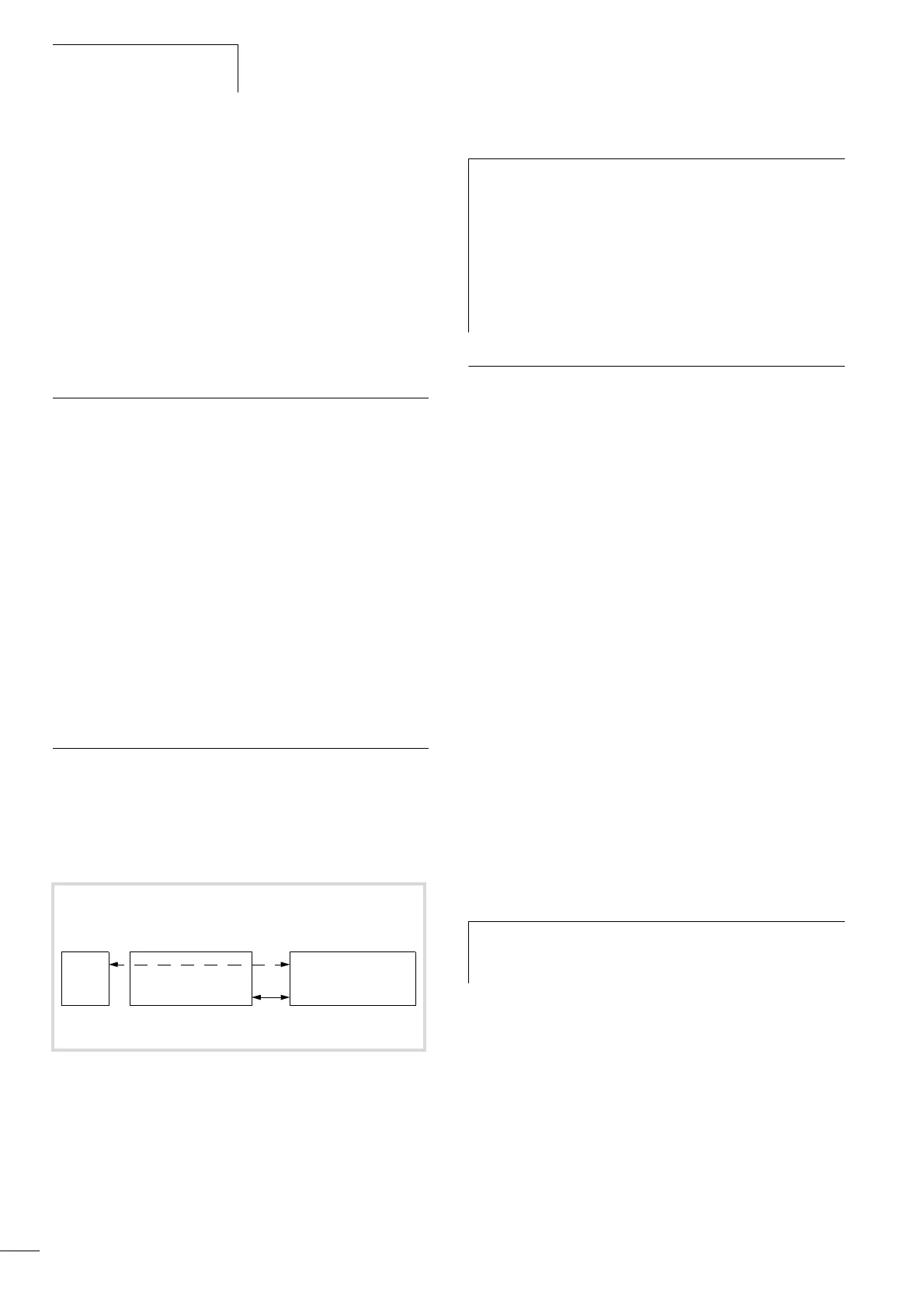

Figure 76: XC100/200, XN-PLC on the CANopen bus, routing principle

PC

Routing PLC XC100/

200/XN-PLC

(master/device)

Node ID 1

Target PLC

XC100/200/XN-PLC

(device)

(Routing) Node ID n

1)

Node ID n

1)

CANopen

h

The following applies for the Node ID of the device func-

tion and the Node ID of the routing function:

XC100 with operating system < V2.0 or XC200:

The routing node ID must be not equal to the device

node ID.

XC100 with operating system f V2.0 or XN-PLC:

The (routing) Node ID must be equal to the Node ID

(device)!

h

In order to guarantee a speedy transfer of data, the

routing with the CANopen should only be performed with

a baud rate of at least 125 Kbit/s.

Loading...

Loading...