Chapter 1: INTRODUCTION

8

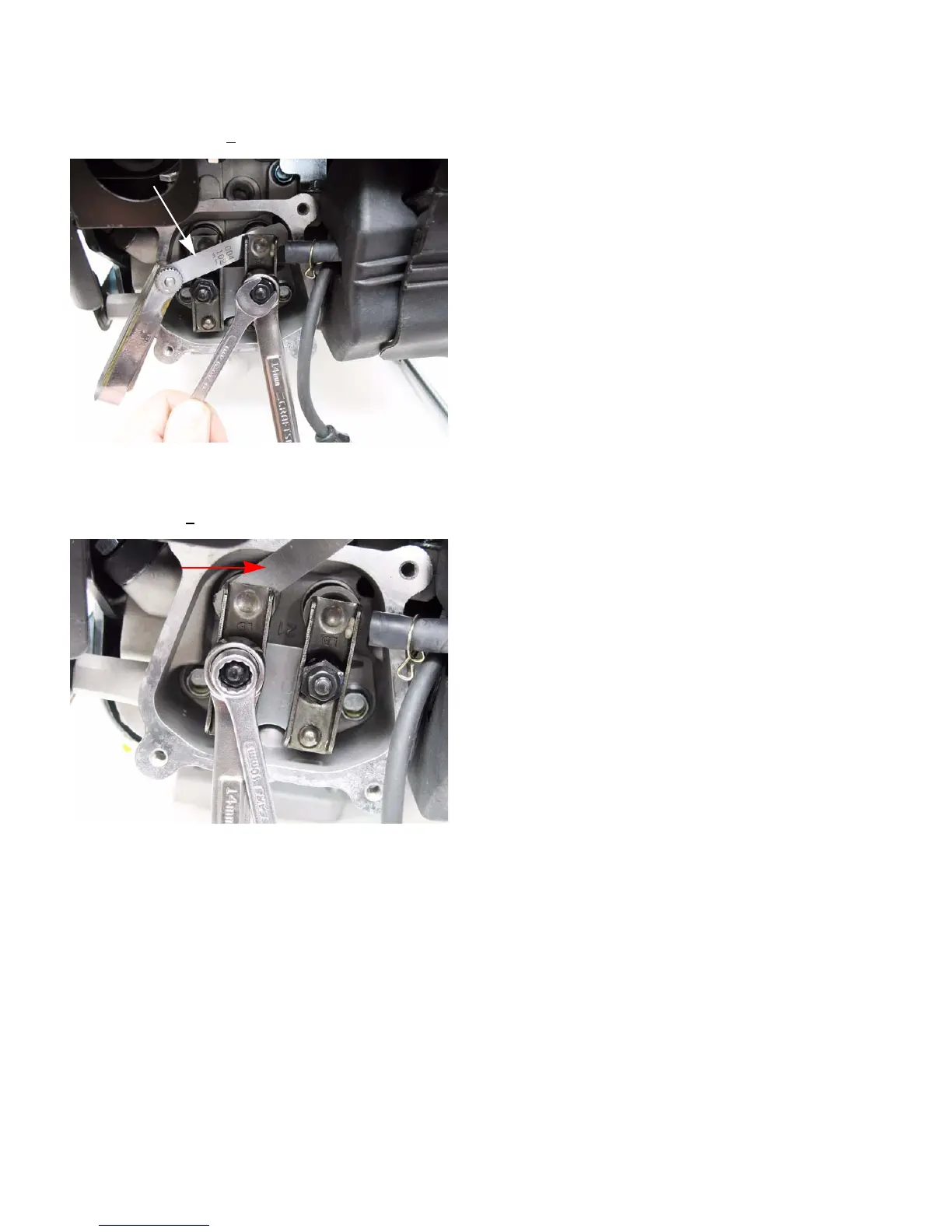

9. Intake valve lash (carburetor side) should be

.003”-.005” (.10

+ .02mm). See Figure 1.10.

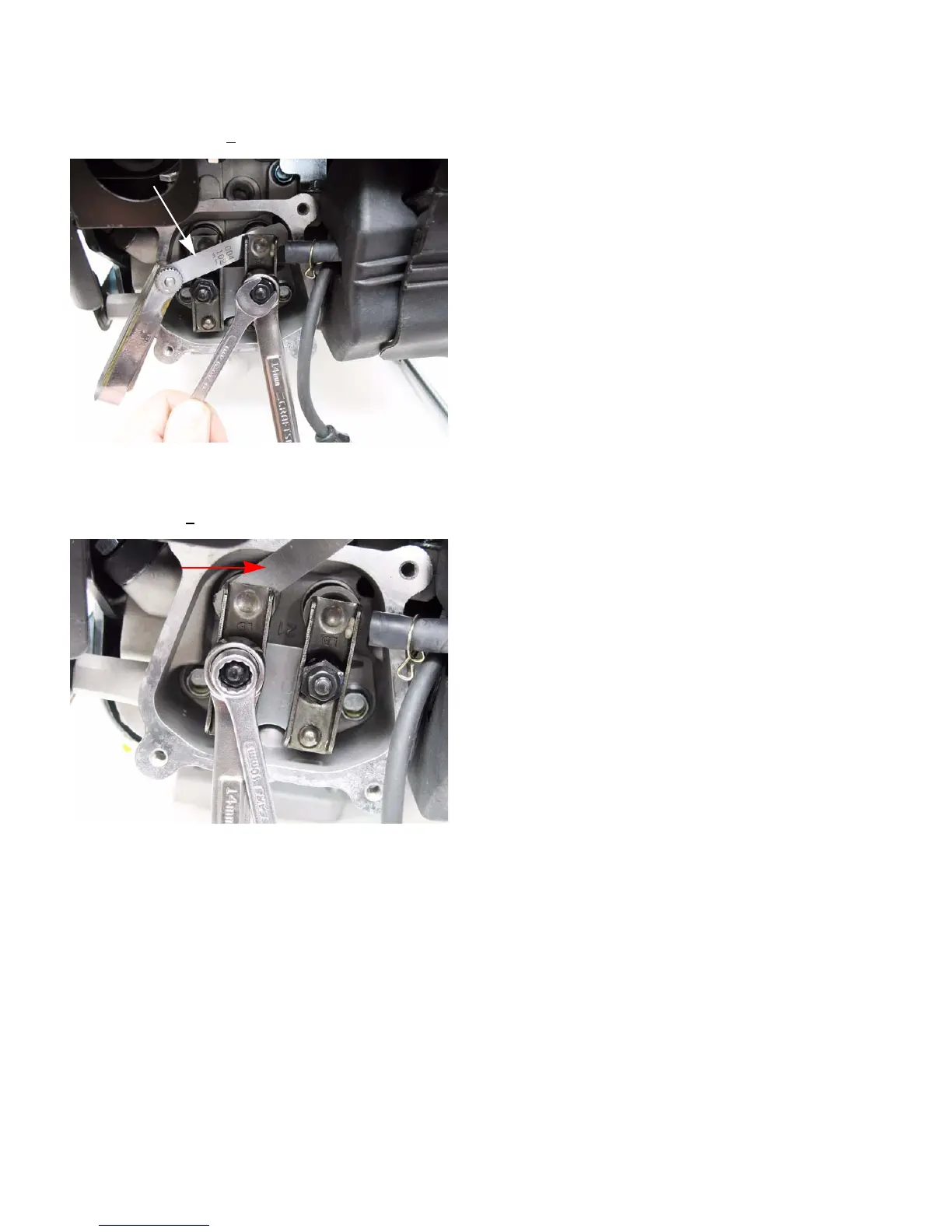

10. Exhaust valve lash (muffler side) should be .005-

.007” (.15

+ .02mm). See Figure 1.11.

11. Use a 10mm wrench to loosen the jam nut, and

a 14mm wrench to adjust the rocker arm fulcrum

nut.

See Figure 1.11.

• Tighten the rocker arm fulcrum nut to close-up

the clearance between the end of the valve stem

and the contact point on the rocker arm.

• Loosen the rocker arm fulcrum nut to open-up

the clearance between the end of the valve stem

and the contact point on the rocker arm.

12. Hold the fulcrum nut with a 14mm wrench,

tighten the jam nut to a torque of 79.7 - 106.2 in-

lb. (9-12 Nm) using a 10mm wrench.

13. Double-check the clearance after tightening the

jam nut, to confirm that it did not shift. Re-adjust

if necessary.

14. Rotate the engine through several compression

cycles:

• Observe the movement of the valve gear.

• Return the piston to TDC compression stroke

and re-check the valve lash to confirm consistent

movement of the valve gear, including the slight

bump to the exhaust valve from the automatic

compression release.

15. Clean-up any oil around the valve cover open-

ing, clean the valve cover, replace the valve

cover gasket if necessary.

16. Install the valve cover, tightening the valve cover

screws to a torque of 62 - 80 in-lbs (7-9 Nm).

IMPORTANT: Over tightening the valve cover

will cause it to leak.

17. Install the spark plug.

Spark arrestor

The spark arrestor should be checked and/or cleaned

every 25 hours. Clean spark arrestors by following the

steps described in Chapter 8: Exhaust.

NOTE: The spark arrestor also helps to keep

potential blockages out of the exhaust system.

Typical blockages include insect nests built dur

-

ing the dormant season.

Cleaning the engine

1. To maintain a proper operating temperature and

to keep the equipment looking good all debris

should be removed from the engine.

2. It is recommended to use compressed air to

blow all of the debris off of the engine.

NOTE: A pressure washer may be used to clean

outdoor power equipment but only after the unit

has been allowed to properly cool.

NOTE: Debris can build up under the deck and

cause the engine to operate under an unin

-

tended load.

Figure 1.10

.004” feeler

gauge

Figure 1.11

.006” feeler

gauge

www.mymowerparts.com

For Discount White Outdoor Parts Call 606-678-9623 or 606-561-4983

Loading...

Loading...