16

W415-0794 / A / 06.08.10

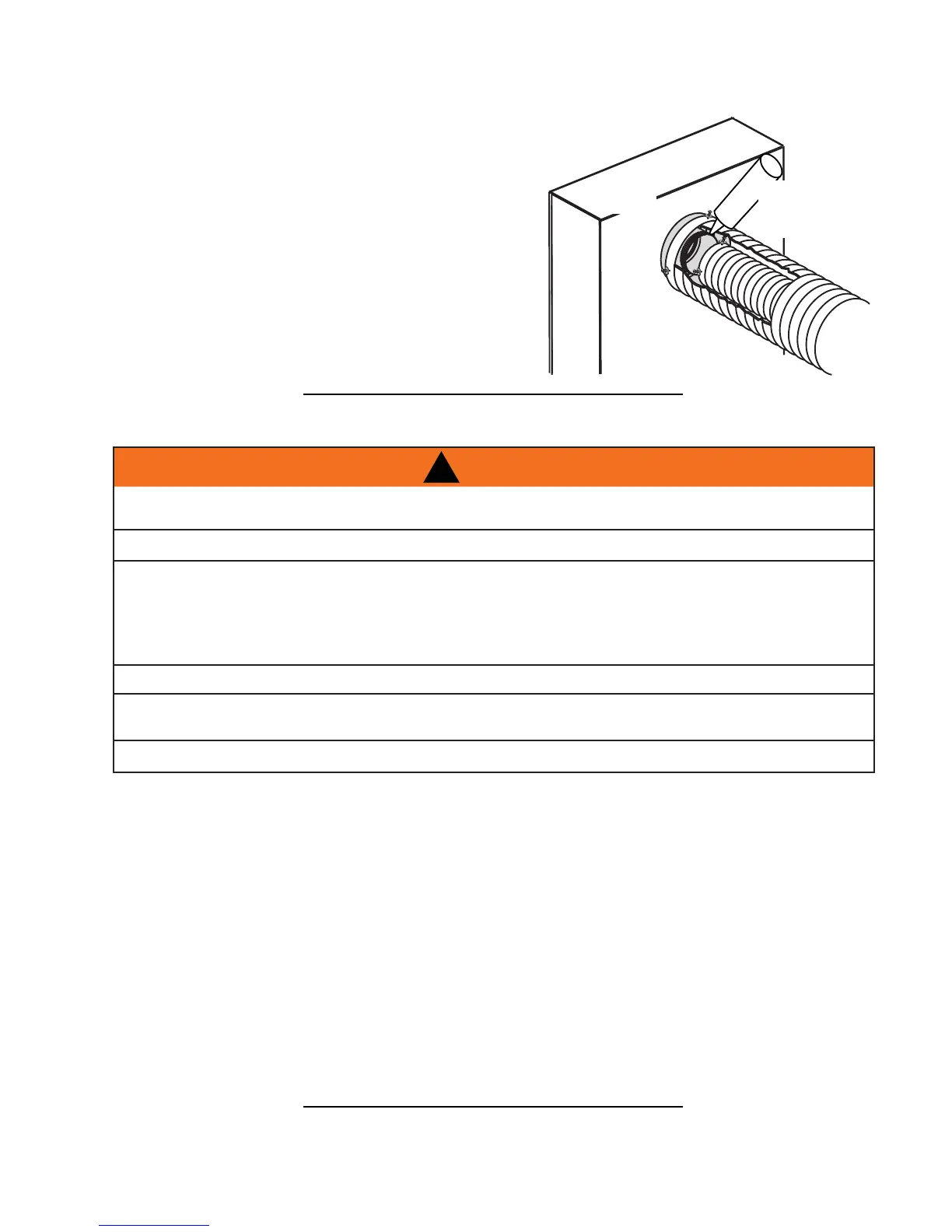

4.4.3 APPLIANCE VENT CONNECTION

A. Install the inner fl ex pipe to the fi replace. Secure with

3 screws and fl at washers. Seal the joint and screw

holes using the high temperature sealant W573-0007

(not supplied).

B. Install the outer fl ex pipe to the fi replace. Attach and

seal the joints using the high temperature sealant

W573-0002 (not supplied).

28.4

HIGH

TEMPERATURE

SEALANT

SCREWS

1

1

/2” OVERLAP

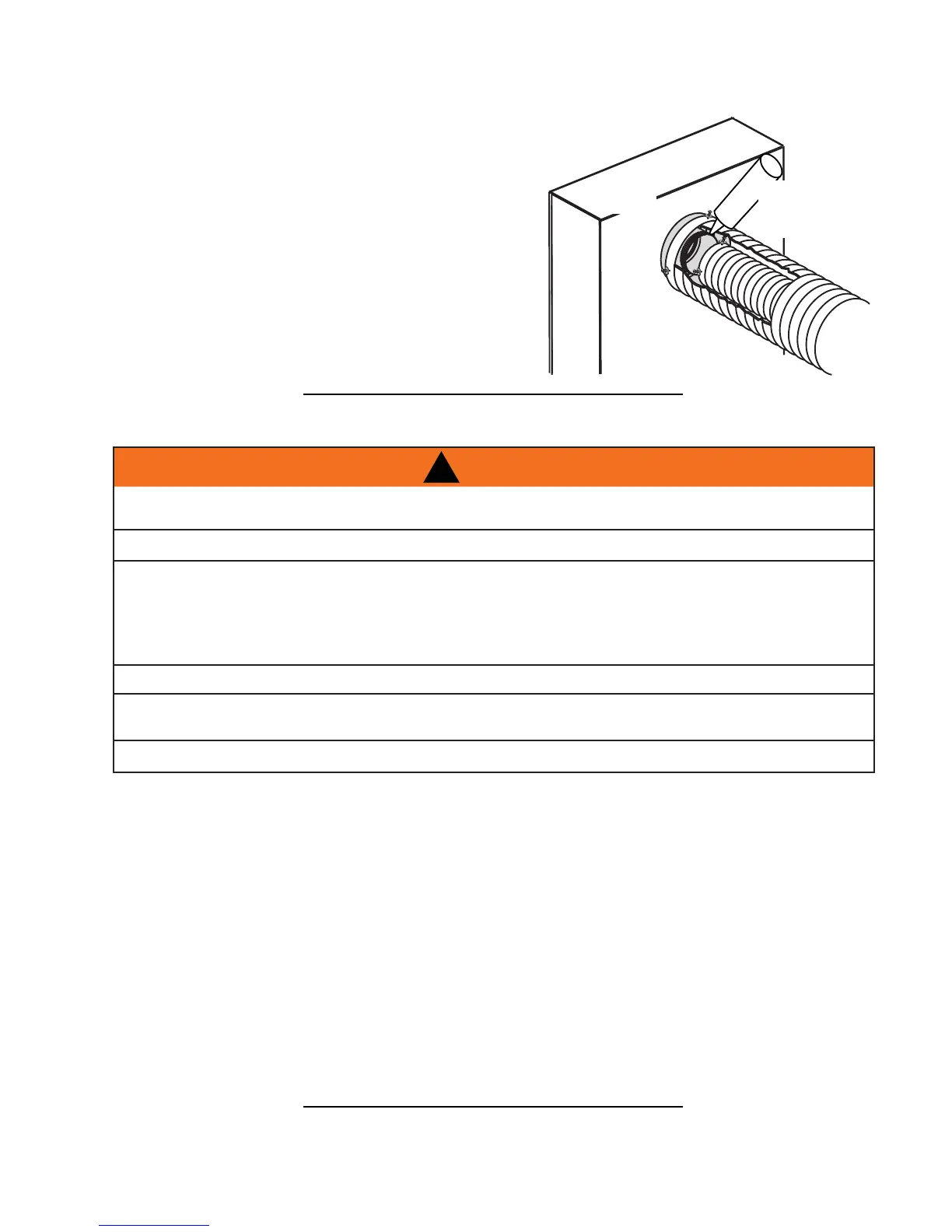

4.5 GAS INSTALLATION

30.1A

Installation and servicing to be done by a qualifi ed installer. Do not use open fl ame.

• Move the appliance into position and secure.

• If equipped with a fl ex connector the appliance is designed to accept a 1/2” gas supply. Without the

connector it is designed to accept a 3/8” gas supply. The appliance is equipped with a manual shut off

valve to turn off the gas supply to the appliance.

• Connect the gas supply in accordance to local codes. In the absence of local codes, install to the

current CAN/CSA-B149.1 Installation Code in Canada or to the current National Fuel Gas Code, ANSI

Z223.1 / NFPA 54 in the United States.

• When fl exing any gas line, support the gas valve so that the lines are not bent or kinked.

• The gas line fl ex-connector should provide suffi cient movement to permit shifting the burner assembly

on it’s side.

• Check for gas leaks by brushing on a soap and water solution.

!

WARNING

RISK OF FIRE, EXPLOSION OR ASPHYXIATION. ENSURE THERE ARE NO IGNITION SOURCES SUCH AS

SPARKS OR OPEN FLAMES.

SUPPORT GAS CONTROL WHEN ATTACHING GAS SUPPLY PIPE TO PREVENT DAMAGING GAS LINE.

ALWAYS LIGHT THE PILOT WHETHER FOR THE FIRST TIME OR IF THE GAS SUPPLY HAS RUN OUT

WITH THE GLASS DOOR OPENED OR REMOVED. PURGING OF THE GAS SUPPLY LINE SHOULD BE

PERFORMED BY A QUALIFIED SERVICE TECHNICIAN. ASSURE THAT A CONTINUOUS GAS FLOW IS AT

THE BURNER BEFORE CLOSING THE DOOR. ENSURE ADEQUATE VENTILATION. FOR GAS AND

ELECTRICAL LOCATIONS, SEE “DIMENSION” SECTION.

ALL GAS CONNECTIONS MUST BE CONTAINED WITHIN THE APPLIANCE WHEN COMPLETE.

HIGH PRESSURE WILL DAMAGE VALVE. DISCONNECT GAS SUPPLY PIPING BEFORE TESTING GAS

LINE AT TEST PRESSURES ABOVE 1/2 PSIG.

VALVE SETTINGS HAVE BEEN FACTORY SET, DO NOT CHANGE.

4.5.1

4.5.2

4.5.3

4.5.4

4.5.5

4.5.6

Loading...

Loading...