ENGLISH – 23

9.1.4 FT210B photosensor

The FT210B photosensor combines in a single device a force

limiting system (type C, in accordance with the EN12453 stand-

ard) and a presence sensor that detects obstacles on the line

of sight between the TX transmitter and RX receiver (type D, in

accordance with the EN12453 standard). In the FT210B photo-

sensor, the signals regarding the status of the sensitive edge

are sent through the photocell range, integrating the 2 systems

in a single device. The transmitting element located on the mov-

ing leaf is battery-powered, which eliminates visually unpleasant

connection systems; special circuits reduce battery consump-

tion, ensuring up to 15 years’ life (see estimation details in the

product’s instructions).

A single FT210B device combined with a sensitive edge (TCB65,

for example) allows for attaining the level of safety of the “prima-

ry edge” required by the EN12453 standard for all “types of use”

and “types of activation”.

The FT210B photosensor combined with the “resistive” sensitive

edges (8.2 kΩ) is safe against faults (category 3 pursuant to the

EN 13849-1 standard). It is equipped with a special anti-colli-

sion circuit to prevent interference with other detectors, even

not synchronised, and allows for adding other photocells; for

example, in case of transit of heavy vehicles, where a second

photocell is normally positioned 1 m above the ground.

l

Consult the FT210B instruction manual for further

information on the connection and addressing

methods.

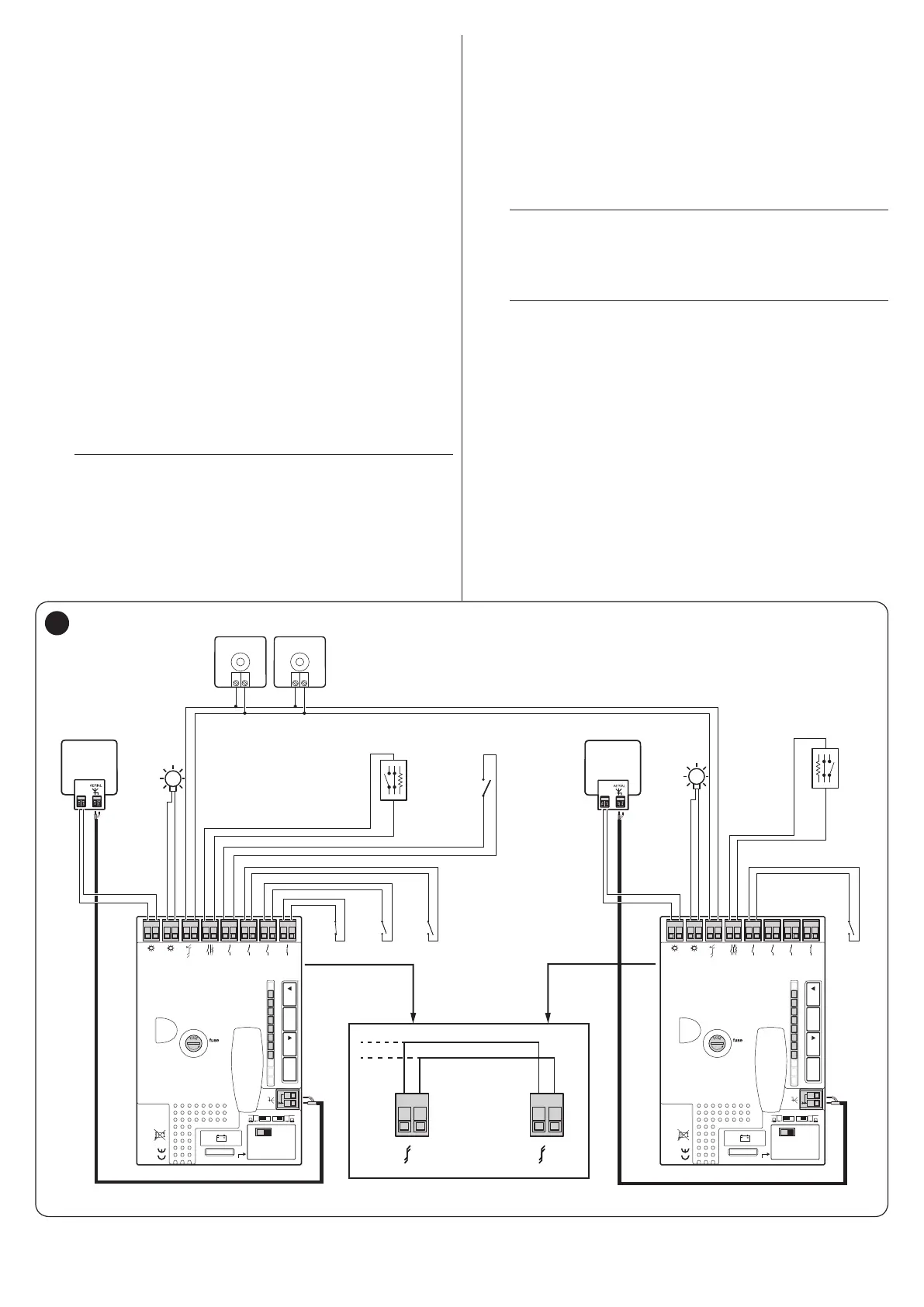

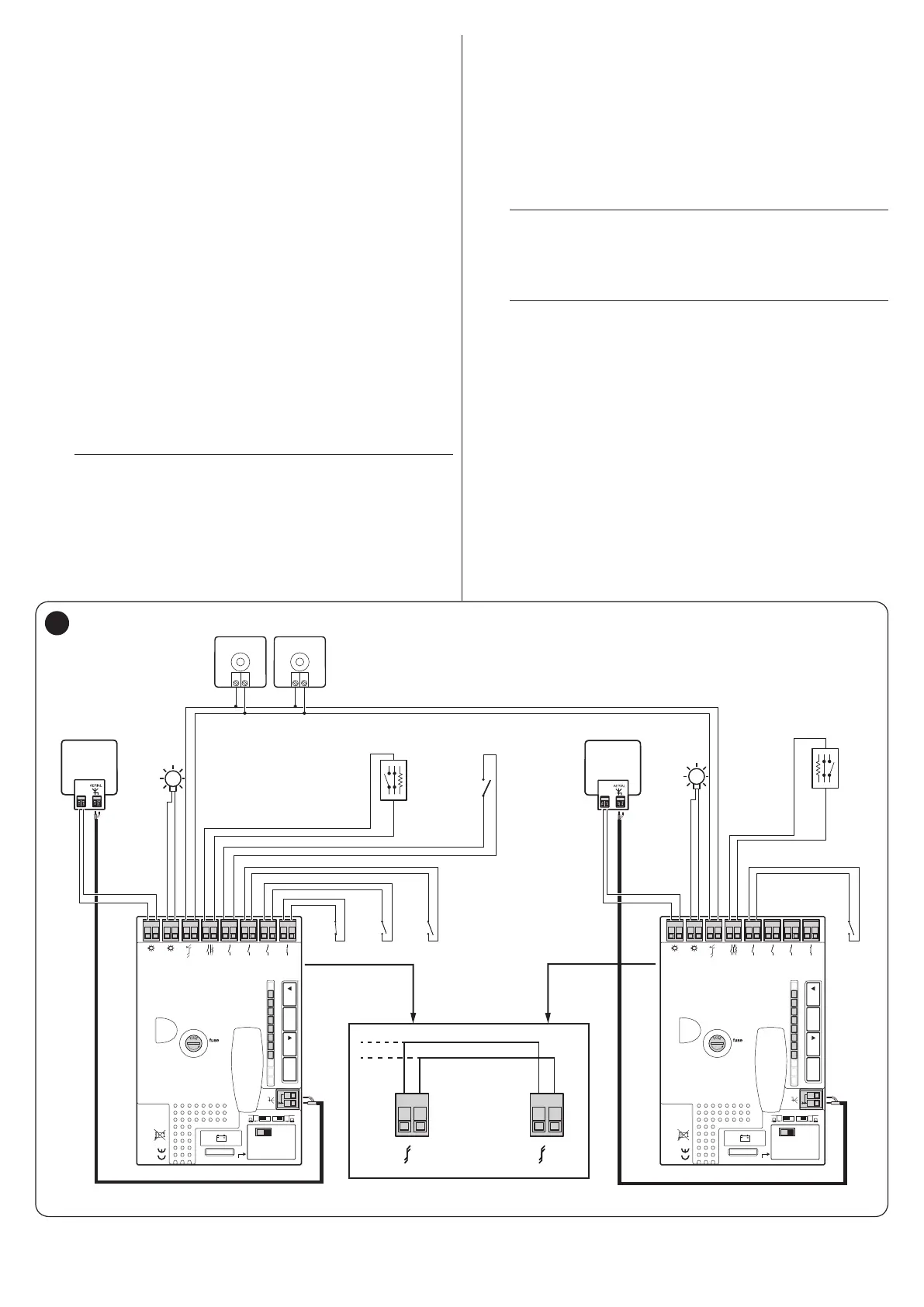

9.1.5 Gearmotor in SLAVE mode

The motor can function in SLAVE mode by suitably program-

ming and connecting it; this operating mode is used to automate

two opposite leaves that must move in a synchronised manner.

In this mode, a motor functions as MASTER, in other words, it

commands the manoeuvres, while the second motor functions

as SLAVE, executing the commands sent by the MASTER (all

the motors are MASTER by default).

The connection between MASTER and SLAVE is made via Blue-

BUS.

m

In this case, the polarity of the connections between

the two motors must be observed, as illustrated in

“Figure 36” (the other devices will continue not hav-

ing polarity).

l

It is not important which motor functions as MAS-

TER or SLAVE; the choice must take into account

the ease of the connections and the fact that the

“Step-by-Step” command of the SLAVE device al-

lows the full opening of the SLAVE leaf only.

Perform the following operations to install two motors in MASTER

and SLAVE mode:

1. install the two motors

2. connect the two motors as shown in “Figure 36”

Receiver

1.6AT

Flash

Bluebus

Stop

Sbs

Open

Aerial

Close

Aux In

L1L2L3L4L5L6L7L8

OpenStop/SetClose

OGI

FLASH

CLOSE

OPEN

AUX IN

NO NO

NC

Receiver

1.6AT

Flash

Bluebus

Stop

Sbs

Open

Aerial

Close

Aux In

L1L2L3L4L5L6L7L8

OpenStop/SetClose

OGI

FLASH

24V 4W

OGI

24V 4W

OGI

NO

TX

1 2

RX

1 2

NO

NC

8K2

Bluebus

MASTER

Bluebus

SLAVE

Bluebus

Bluebus

21 21

MASTER Board SLAVE Board

STOP

NO

NC

8K2

SBS

NO

IBT4N

IBT4N

36

Loading...

Loading...