ENGLISH – 3

– The manufacturer declines all liability for damages to

property, objects or people resulting from failure to

observe the assembly instructions. In such cases, the

warranty for material defects shall not apply.

– The weighted sound pressure level of the emission A is

lower than 70 dB(A).

– Cleaning and maintenance reserved for the user must

not be carried out by unsupervised children.

– Before working on the system (maintenance, cleaning),

always disconnect the product from the mains power

supply.

– Inspect the system frequently, in particular the cables,

springs and supports to detect any imbalances and

signs of wear or damage. Do not use the product if it

needs to be repaired or adjusted, because defective

installation or incorrect balancing of the automation can

lead to injuries.

– The packing materials of the product must be disposed

of in compliance with local regulations.

– Keep persons away from the gate when it is manoeu-

vred using the control elements.

– When operating the gate, keep an eye on the automat-

ed mechanism and keep all bystanders at a safe dis-

tance until the movement has been completed.

– Do not operate the product if anyone is working near-

by; disconnect its power supply before permitting such

work to be done.

– If the power cable is damaged, it must be replaced by

the manufacturer or by an appointed servicing compa-

ny or similarly qualied person in order to prevent any

form of risk.

1.2 INSTALLATION WARNINGS

– Prior to installing the drive motor, check that all me-

chanical components are in good working order and

properly balanced, and that the automation can be ma-

noeuvred correctly.

– If the gate being automated has a pedestrian gate, the

system must be equipped with a control device that in-

hibits the motor’s operation when the pedestrian gate

is open.

– Make sure that the control elements are kept far from

moving parts but nonetheless directly within sight. Un-

less a selector is used, the control elements must be

installed at least 1.5 m above the ground and must not

be accessible.

– If the opening movement is controlled by a re-sensing

system, make sure that any windows larger than 200

mm are closed using the control elements.

– Prevent and avoid any form of entrapment between the

moving and xed parts during the manoeuvres.

– Permanently afx the label concerning the manual ma-

noeuvre near its actuating element.

– After installing the drive motor, make sure that the

mechanism, protective system and all manual manoeu-

vres function properly.

PRODUCT DESCRIPTION AND

INTENDED USE

2

2 PRODUCT DESCRIPTION AND INTENDED USE

SLH400 is a gearmotor designed for automating residential slid-

ing gates.

The product incorporates an electronic control unit with a pin

connector. The electrical connections with external devices are

simplied thanks to use of the “BlueBUS”, a technique that al-

lows for connecting multiple devices with only 2 wires.

If powered from the mains, SLH400 can house a back-up bat-

tery (model PS124, optional accessory) which, in case of a pow-

er outage (blackout), guarantees that the automation can com-

plete a few manoeuvres.In the event of power outage, it is still

possible to move the gate leaf by unlocking the gearmotor with

the appropriate key (see the “Manually unlocking and locking

the gearmotor” paragraph).

The automation allows for installing various accessories to in-

crease its functions and improve safety.

a

Any use of the product other than the intended use

described is not allowed!

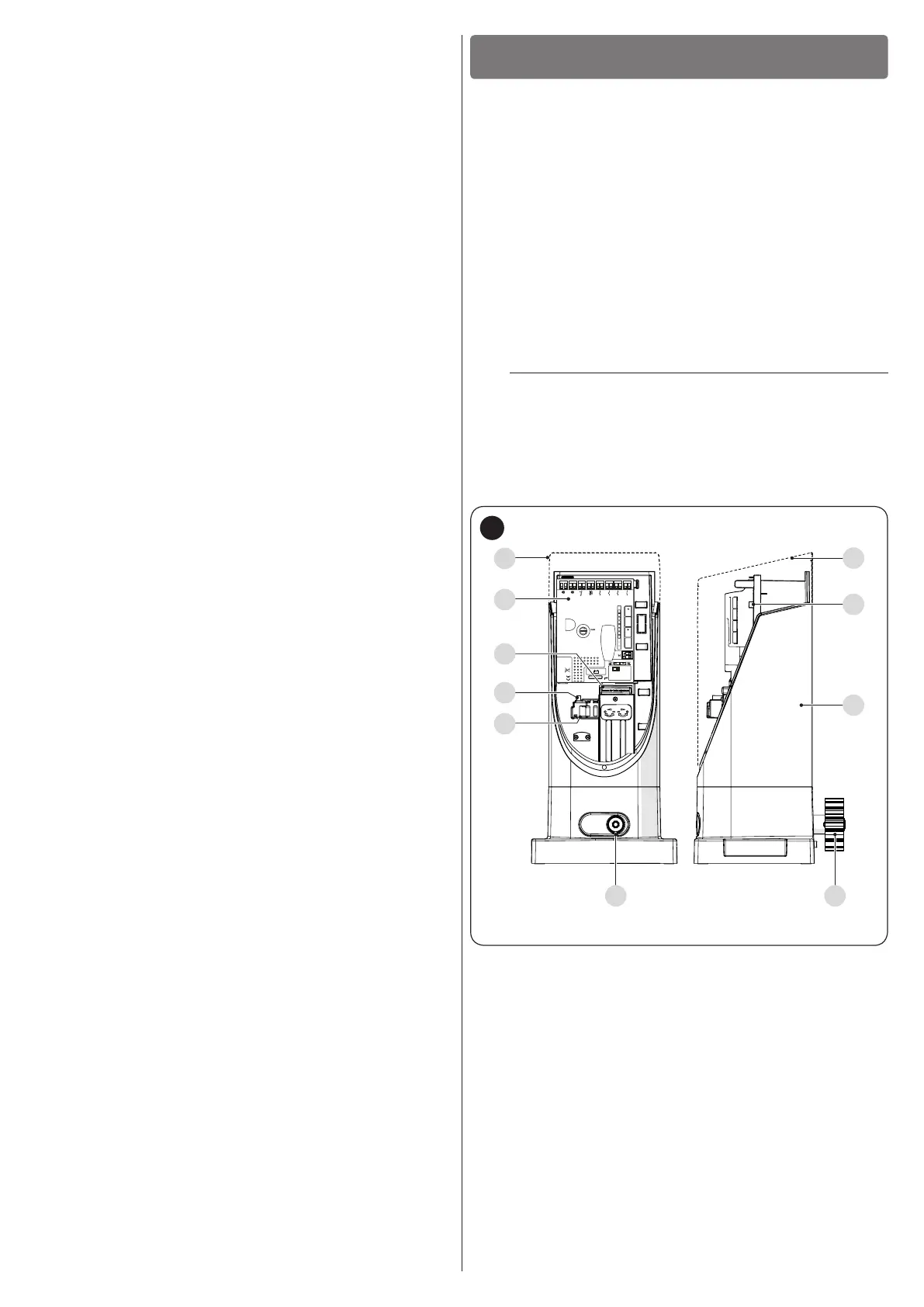

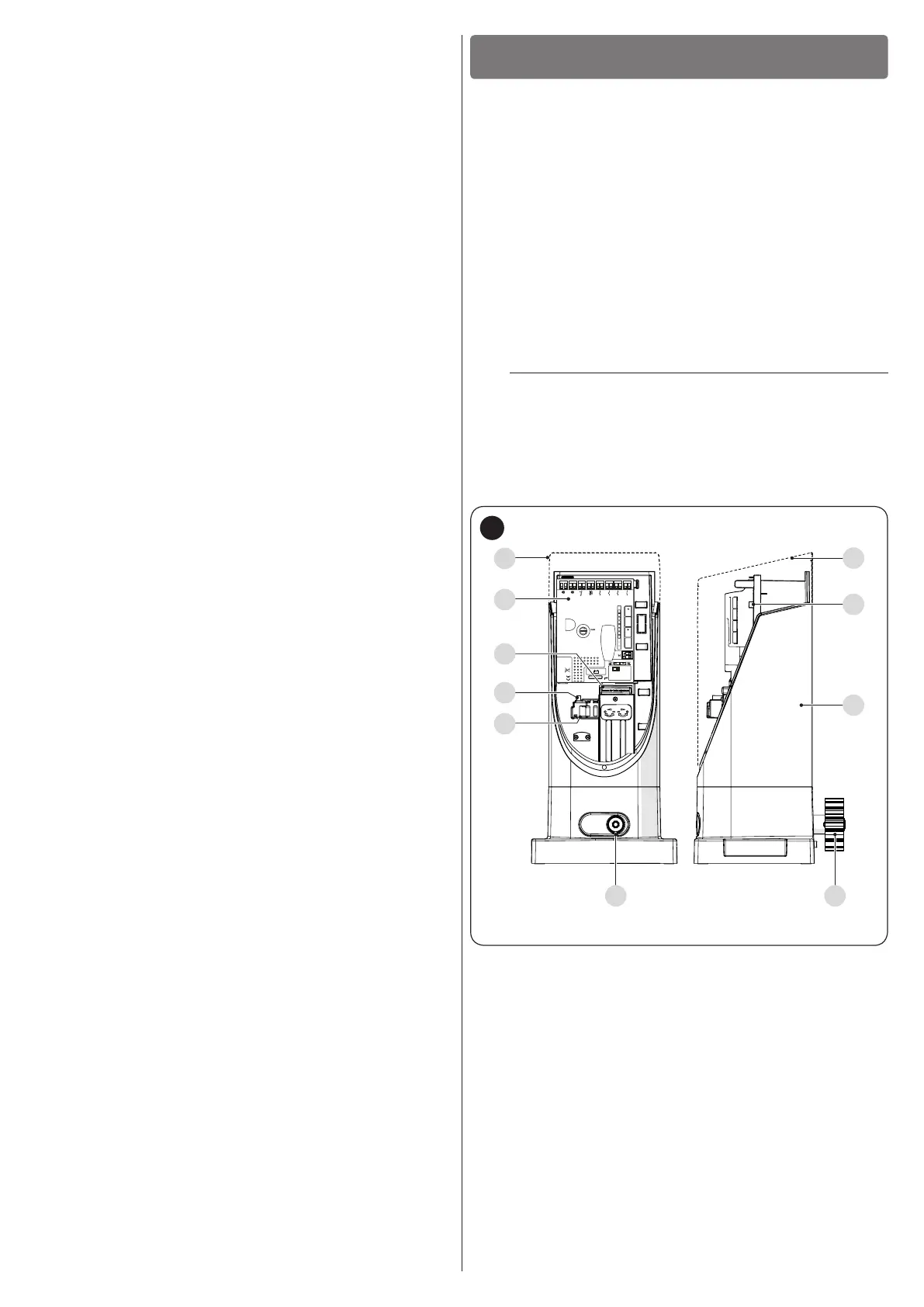

2.1 LIST OF CONSTITUENT PARTS

SLH400 combines an electronic control unit with a pin connec-

tor. “Figure 1” shows the main parts making up the product.

Receiver

1.6AT

Flash

Bluebus

Stop

Sbs

Open

Aerial

Close

Aux In

L1L2L3L4L5L6L7L8

OpenStop/SetClose

OGI

B

C

D

E

I

H

IBT4N

1

A Top cover

B Electronic control and command unit

C Limit switch position regulators

D Fuse

E Power supply connector

F Lock for the unlocking key

G Pinion

H Side cover

I Cable pass-through rings

Loading...

Loading...