4 – ENGLISH

INSTALLATION

3

3 INSTALLATION

3.1 PRE-INSTALLATION CHECKS

a

The installation must be carried out by qualied

personnel in compliance with the current legisla-

tion, standards and regulations, and with the in-

structions provided in this manual.

Before proceeding with the product’s installation, it is necessary

to:

– check the integrity of the supply

– check that all the materials are in good working order and

suited to the intended use

– make sure that the structure of the gate is suitable for being

automated

– make sure that the weight and dimensions of the gate leaf

fall within the operating limits specied in the “Product usage

limits” paragraph

– check that the force required to start moving the gate leaf is

less than half the “maximum torque”, and that the force re-

quired to keep the gate leaf moving is less than half the “nomi-

nal torque”; compare the resulting values with those specied

in the “TECHNICAL SPECIFICATIONS” chapter. The manu-

facturer recommends a 50% margin on the force, as unfavour-

able climatic conditions may cause increased friction.

– verify that there are no points of greater friction during the

opening and closing movements along the entire gate path

– verify that there is no risk of derailment of the leaf or that it may

come off the guides

– verify that the overrun mechanical stops are sturdy enough

and that they do not deform even if the leaf should strike them

forcefully

– verify that the gate leaf is well balanced: it must not move by

itself when left in any position

– make sure that the installation area is not subject to ooding; if

necessary, the product must be installed appropriately raised

above ground level

– verify that the area where the gearmotor is installed allows for

unlocking the latter and manoeuvring easily and safely

– verify that the mounting positions of the various devices are

protected against impacts and that the mounting surfaces are

sufciently sturdy

– prevent any parts of the automation from being immersed in

water or other liquids

– keep the product away from heat sources and open ames

and acid, saline or potentially explosive atmospheres; these

may damage the product and cause malfunctions or danger-

ous situations

– if there is an access door in the gate, or within its range of

movement, make sure that it does not obstruct the gate’s nor-

mal path; install an appropriate interlock system if necessary

– connect the control unit to an electricity supply line equipped

with a safety earthing system

– connect the gate to the earthing device in accordance with

the current legislation

– include a device on the electric power line ensuring complete

disconnection of the automation from the grid. The disconnec-

tion device must have contacts with a sufcient gap to ensure

complete disconnection, under the Category III overvoltage

conditions, in accordance with the installation instructions.

Should it be necessary, this device guarantees fast and safe

disconnection from the power supply; it must therefore be po-

sitioned in view of the automation. If placed in a non-visible

location, it must have a system that blocks any accidental on

unauthorised reconnection of the power supply, in order to

prevent dangerous situations. The disconnection device is not

supplied with the product.

3.2 PRODUCT USAGE LIMITS

The data relative to the product’s performances is included in

the “TECHNICAL SPECIFICATIONS” chapter and is the only

data that allows for properly assessing whether the product is

suitable for its intended use.

The structural characteristics of the product make it suitable for

use on sliding gates, according to the limits indicated in the fol-

lowing tables.

The actual suitability of the product to automate a specic slid-

ing gate depends on friction and on other factors, even occa-

sional, such as the presence of frost, which may interfere with

the gate leaf’s movement.

For an effective check, it is essential to measure the force nec-

essary to move the gate leaf along its entire path and ensure

that this is less than half of the “nominal torque” indicated in

“TECHNICAL SPECIFICATIONS” chapter (a 50% margin on

the force is recommended, as unfavourable climatic conditions

may cause increased friction); furthermore, it is necessary to

take into account that shown in the following tables to dene the

number of cycles/hour, the consecutive cycles and maximum

speed allowed.

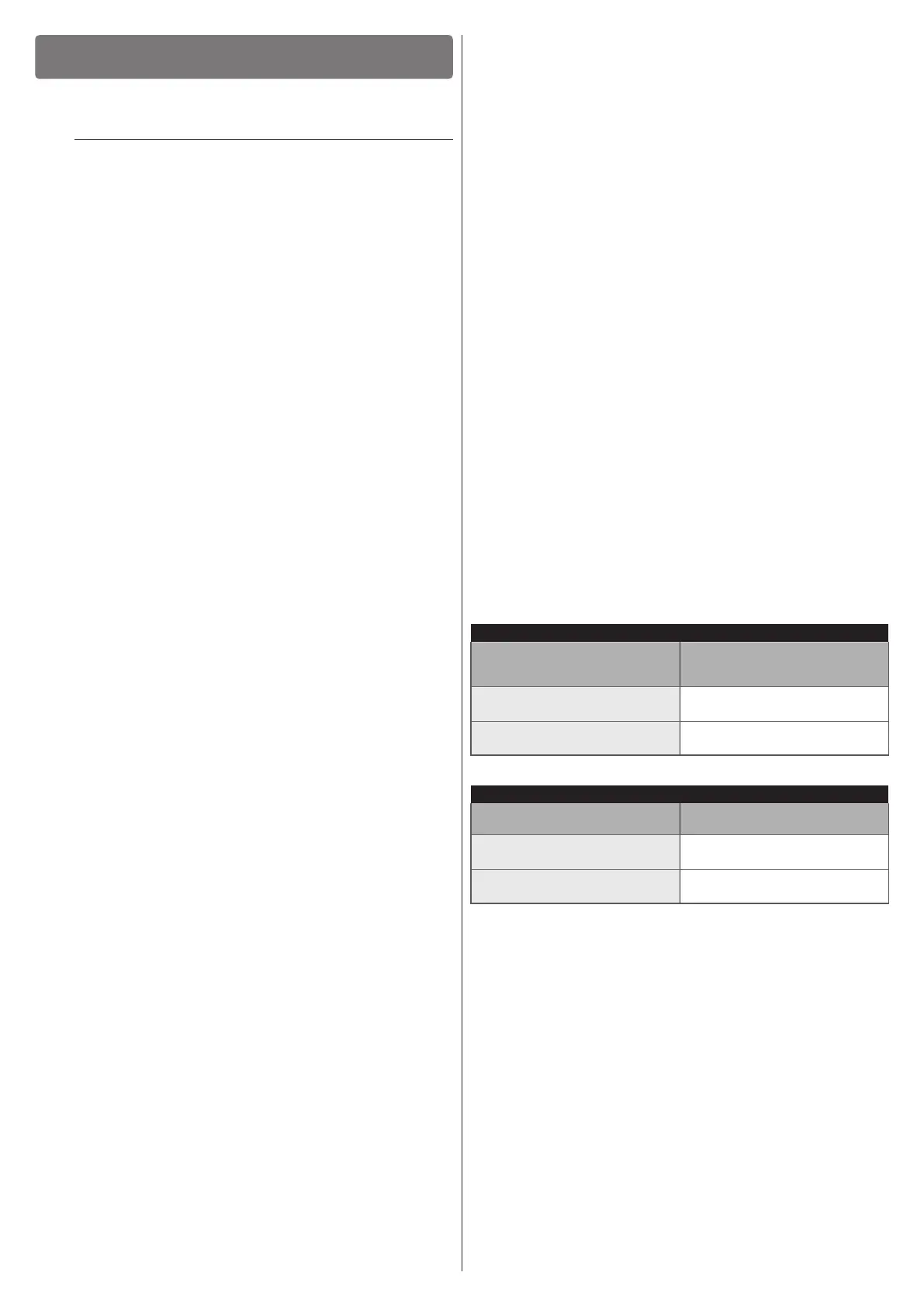

Table 1

SLH400 - LIMITS IN RELATION TO THE GATE LEAF LENGTH

Gate leaf length (m)

Maximum no. of cycles/hour

Maximum no. of consecutive

cycles

Up to 4

35

14

4 ÷ 6

23

11

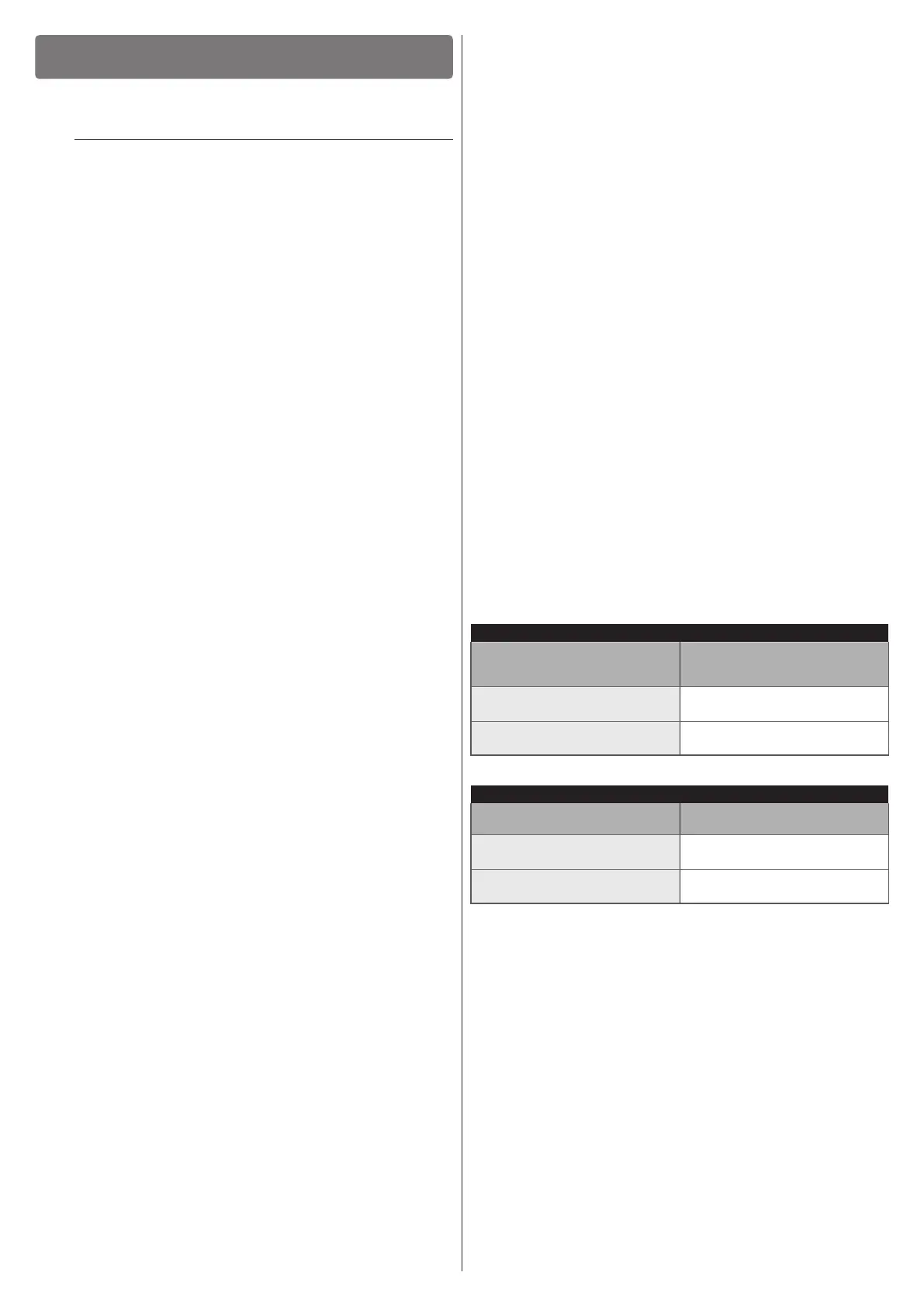

Table 2

SLH400 - LIMITS IN RELATION TO THE GATE LEAF WEIGHT

Gate leaf weight (kg)

Percentage of cycles

Maximum speed allowed

Up to 200

100%

V6 = Extremely fast

200 ÷ 400

50%

V5 = Very fast

The length of the leaf is used to determine both the maximum

number of cycles per hour and the consecutive cycles, while

its weight is used to determine the cycle reduction percentage

and the maximum speed allowed; for example, if the leaf is 5 m

long it, we will have 23 cycles/hour and 11 consecutive cycles.

However, if the leaf weighs 350 kg, the cycles must be reduced

to 50%, resulting in 11 cycles/hour and 5 consecutive cycles,

while the maximum speed allowed is V5: “Very fast”. To prevent

overheating, the control unit has a manoeuvre limiter that works

based on the motor force and duration of the cycles, intervening

whenever the maximum limit is exceeded. The manoeuvre limit-

er also measures the ambient temperature and further reduces

the number of manoeuvres in case of particularly high temper-

atures.

Loading...

Loading...