171Service Manual – SC5000 30 - Solution System

Troubleshooting

Detergent Not Flowing

1. Verify that the pickup tube in the

detergent bottle is below the liquid level

of detergent, and is not blocked.

2. Check the detergent tubing for cuts,

damage, or loose connections, especially

on the suction-side between the pump

and bottle.

• A leak on the pressure-side of the

pump will likely show drips or

detergent residue, but a leak on the

suction-side won’t show any outward

signs.

3. Disconnect the outlet tube from the

detergent pump.

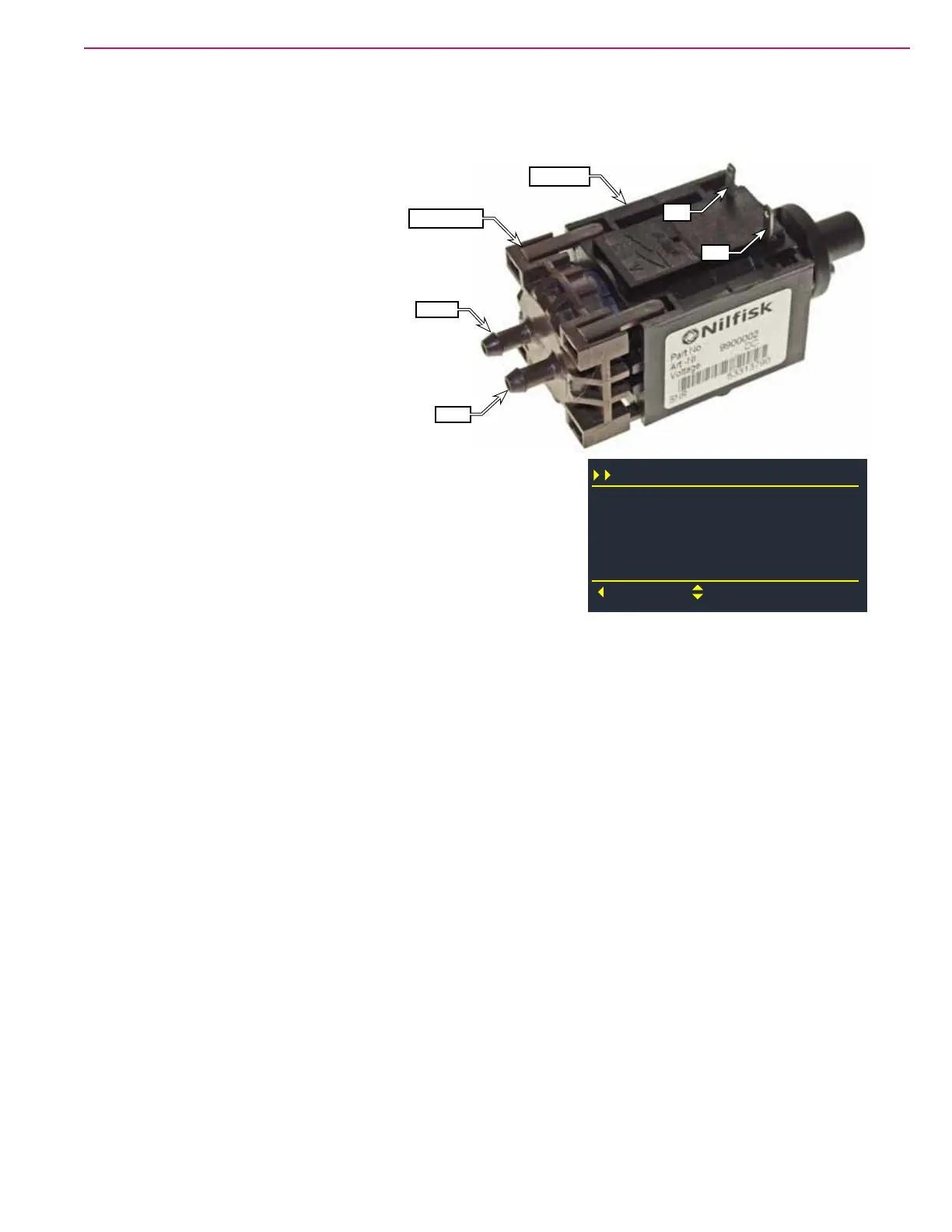

4. Start the machine with Service Mode access, and navigate to the

Service Menu, Output Test, Detergent Pump output.

5. Press the Left arrow to enter the detergent pump screen.

6. Press the up and down arrows to cycle through the 3 options of

Off, Low, and High. Select High.

• You should be able to hear and/or feel the solenoid cycling

approximately every second. If you hear the solenoid cycling, but no uid is exiting the outlet, then

the pump’s diaphragm is broken and the pump needs to be replaced.

• If you do not feel/hear the solenoid cycling, continue below with a voltage check at the pump.

7. Manually operate the pump from the service menu in Low speed.

8. Place a voltmeter across the positive and negative terminals of the solenoid. (An analog voltmeter will

be easier to read the short pulses.)

• If voltage pulses are detected but the solenoid is not cycling, then replace the solenoid.

• If no voltage pulses are detected, continue below to check the connections directly at the MMC.

9. Place the voltmeter probes between J1-4 and J1-5 at the MMC.

• If voltage pulses are detected, repair or replace the wiring between the MMC and the detergent

pump.

• If no voltage pulses are detected, replace the Main Machine Controller.

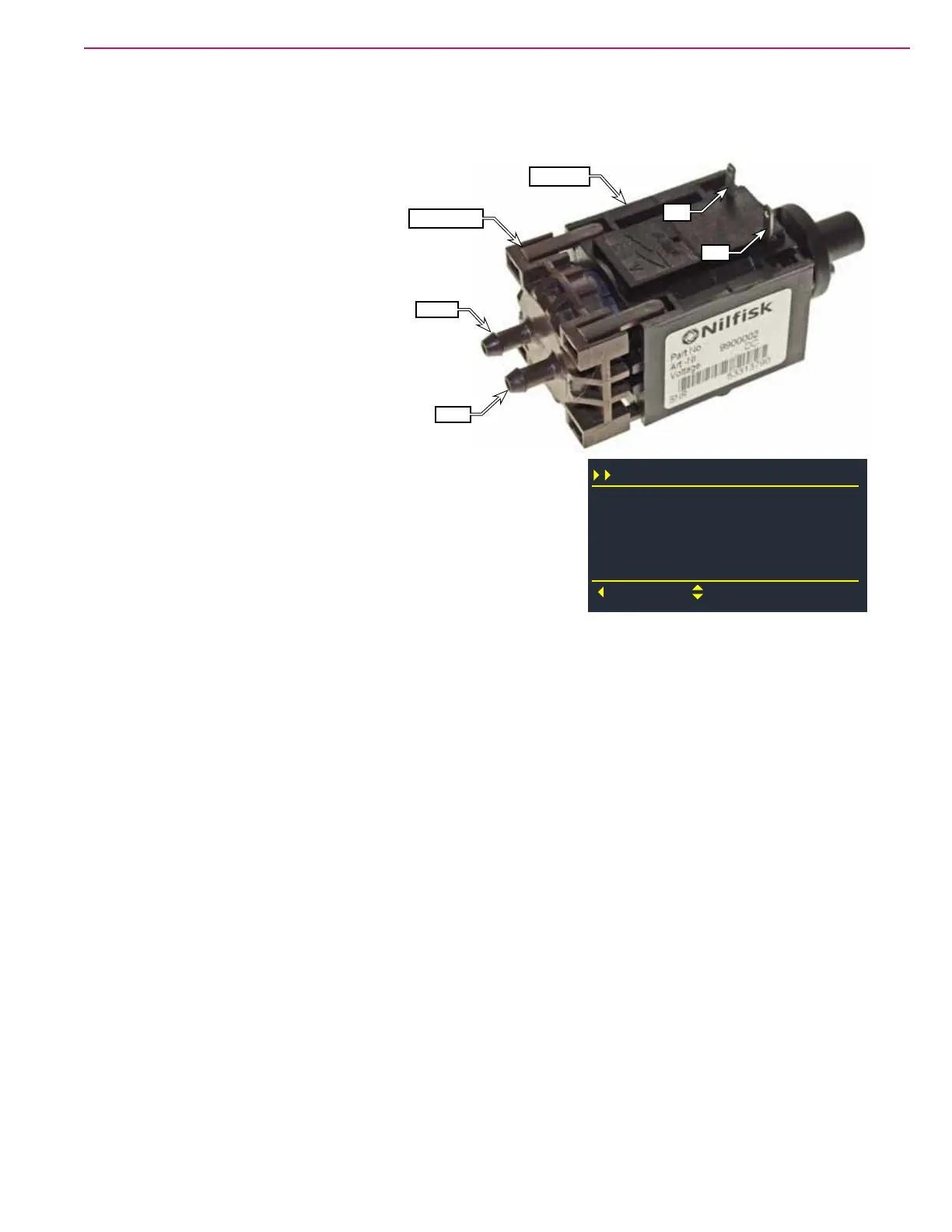

Outlet

Inlet

Pos

Neg

Diaphragm

Solenoid

Output Test

DET PUMP

Back

Set

RIGHT BRUSH

LEFT BRUSH

VACUUM 1

Off

Off

Off

Off

Loading...

Loading...