Wheel System, Traction 206Service Manual – SC6500

™

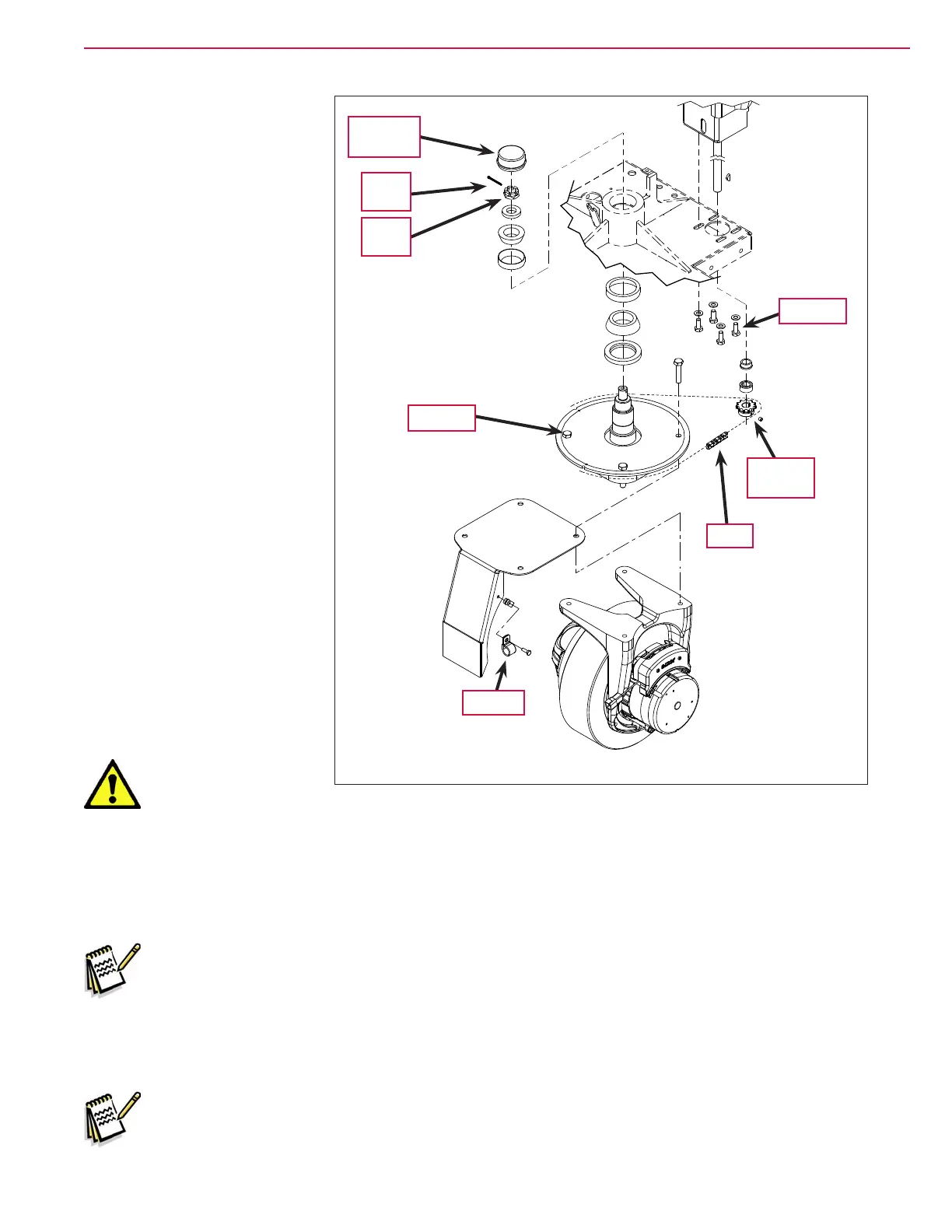

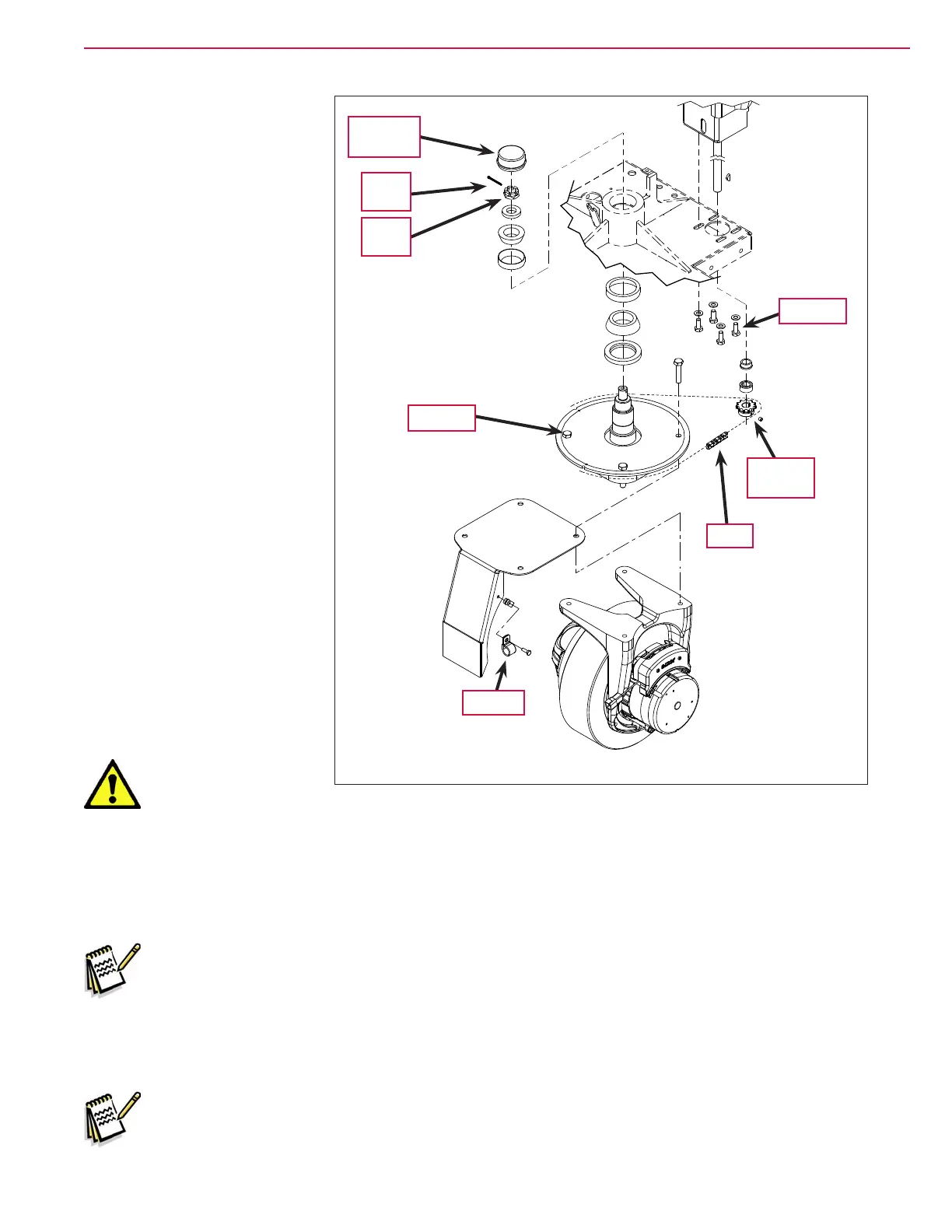

7. Loosen the four Screws from

underneath the front of the

machine and push the lower

steering column toward the

rear of the machine. This

will allow you to separate

the Chain from the Steer

Sprocket

8. Remove the P clamp securing

the wiring harness to the

splash guard and move the

wiring harness aside.

9. Remove the false oor plate

in the operator compartment

(held with three screws) to

allow access to the top spindle

mounting hardware.

10. Remove the Bearing Dust

Cap, Cotter Pin and Castle

Nut from the spindle shaft.

Warning! Never work

under machine without safety stands or blocking to support the machine.

11. Safely jack up or lift up the front of the machine 8-10 inches [20-25 cm] from the center bottom edge of

the solution tank.

12. Carefully guide the wheel motor assembly down and out of its frame opening. Tilt the wheel motor

assembly to the side while raising the machine, then pull it out from underneath the machine.

Note: Be careful not to damage the threads and bearing surfaces when dropping the spindle shaft

down through the frame when removing it from the chassis.

13. Inspect the bearings and seal and replace as needed. If further service work is needed, remove the six

Screws to separate the spindle/steer plate weldment and splash fender from the gear box housing.

14. Reassemble the steering spindle and wheel drive assembly by following the above steps in reverse order.

Note: Tighten the Castle Nut to eliminate any bearing play, then back off the Castle Nut enough

to install a new Cotter Pin.

Chain

Screw (4)

Steer

Sprocket

Bearing

Dust Cap

Cotter

Pin

Castle

Nut

Screw (4)

P-clamp

Loading...

Loading...