9

07610-004-45-09-D

Electrical and grounding conductors must comply with the applicable portions of the

National Electric Code ANSI/NFPA 70 (latest edition) and/or other electrical codes.

The data plate is located on the left-front of the dishmachine. Refer to the data plate for

machine operating requirements, machine voltage, total amperage, and serial number.

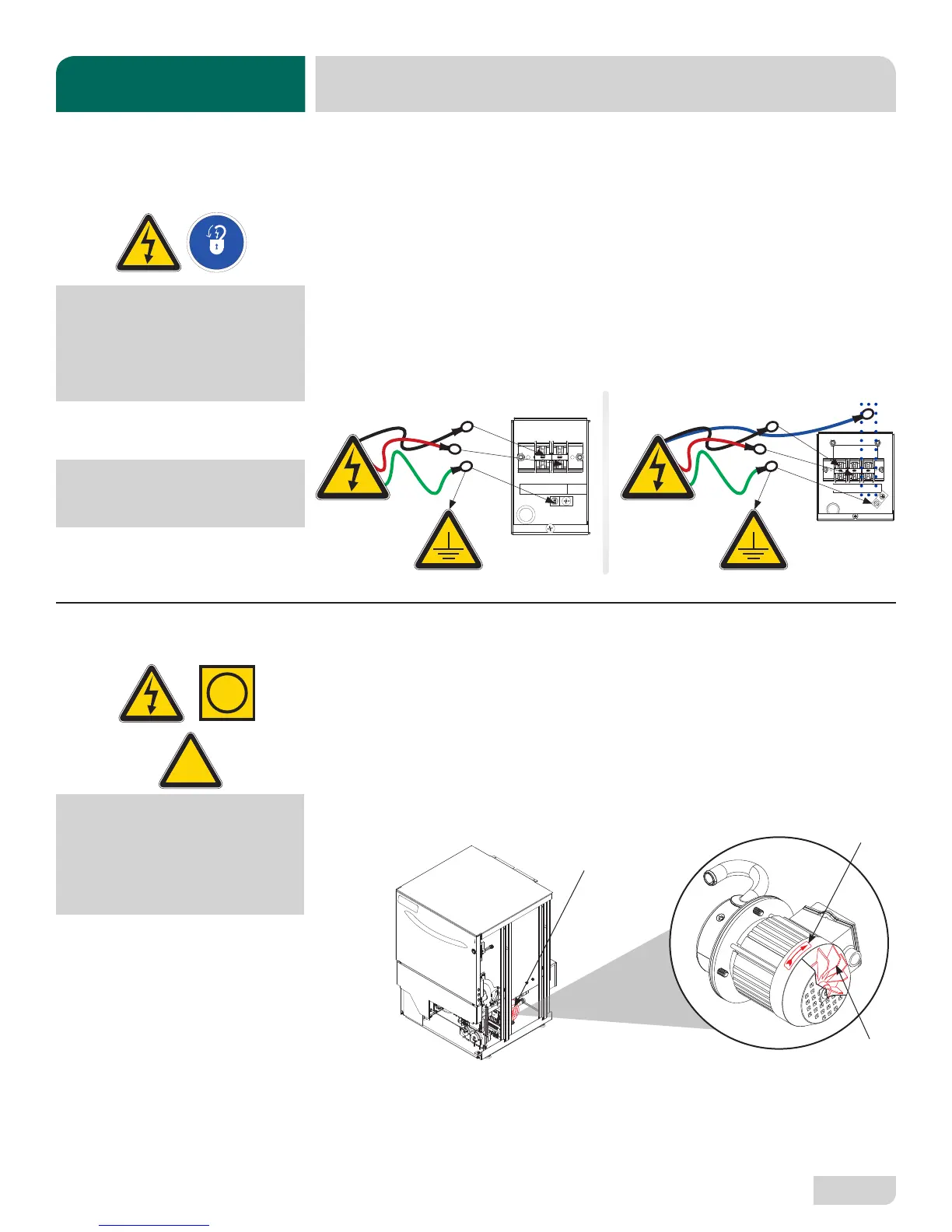

Remove the back panel and set aside. Remove the terminal block box cover. Install

3/4” conduit into the hole in the bottom of the terminal block box. Route power wires and

connect to terminal block. Install the grounding wire onto the lug provided. “DE-OX” or

another similar anti-oxidation agent should be used on all power connections.

208/230 V 460 V

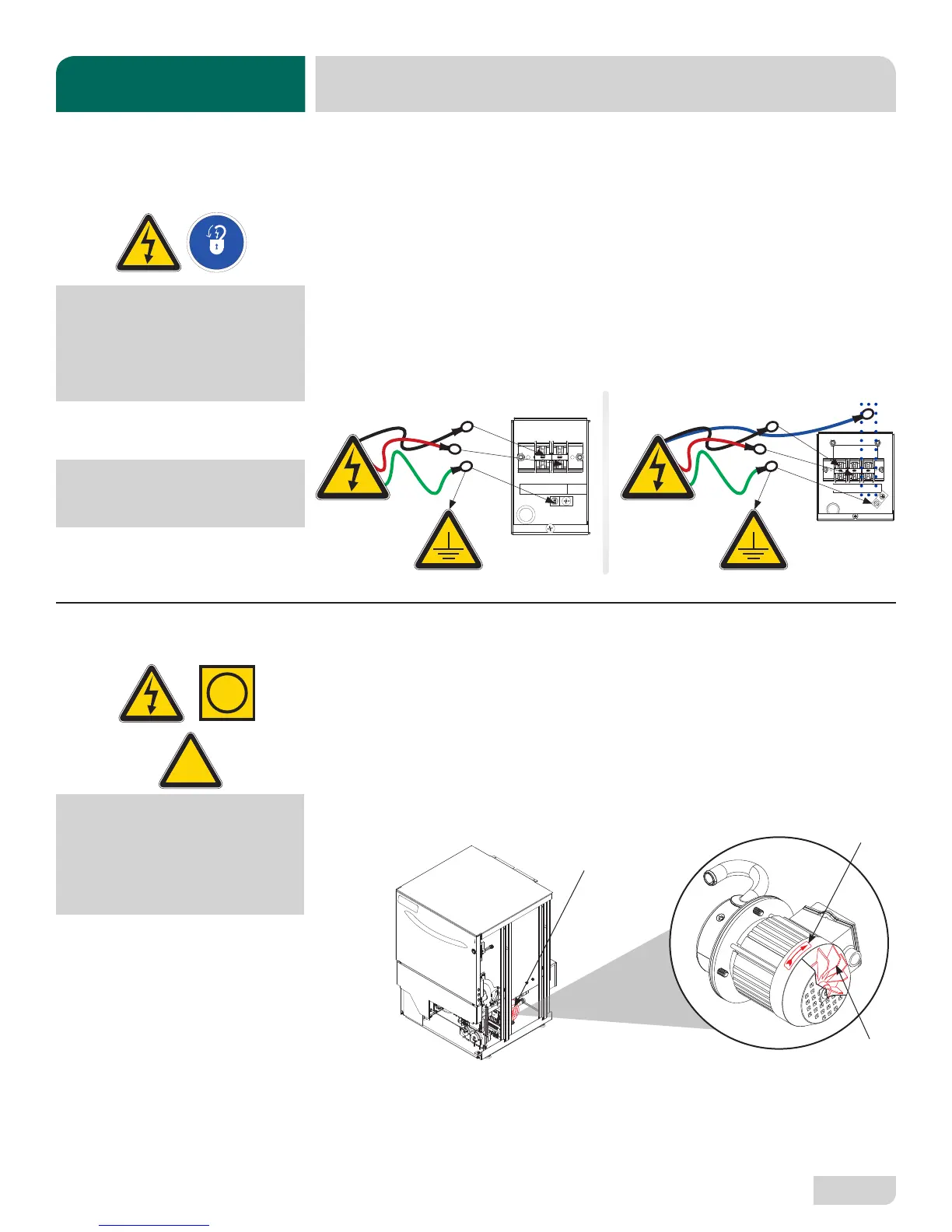

On 3-Phase machines only, correct pump motor rotation must be veried before

the machine is operated. Failure to do so can result in damage to the machine and

components.

1. Follow the "Filling the Wash Tub" section.

2. Using a 7/16 nutdriver, remove front kick panel and keep hardware. Using a

phillips screwdriver, remove right dress panel and keep hardware. Leave start

switch wires connected.

3. Locate the wash pump motor and identify the arrow decal which shows the

correct motor rotation.

4. Press the "Start" button on the right dress panel and immediately open the door.

5. This will stop the cycle. Observe rotation of motor fan.

6. If incorrect, disconnect electrical power and reverse the L1 and L2 connections

at terminal block shown in the section above. Replace panels.

INSTRUCTIONS

INSTALLATION

ELECTRICAL POWER

CONNECTIONS

Disconnect electrical

power at the breaker or

disconnect switch and

tag-out in accordance with

procedures and codes.

L1 N

Ground

L1 L2 L3

Ground

3Φ

On the 460 V machine, the

imbalanced wild leg goes

to L3.

MOTOR ROTATION

i

CAUTION! On 3-Phase

machines only, correct

pump motor rotation

must be veried

before operation!

!

CAUTION

Motor Fan

Wash Pump Motor

Arrow Decal

Loading...

Loading...