E Series Automated Dispensing System

52 www.nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

How to Set Mark Points

If the location and / or orientation of a workpiece changes, the system can automatically adjust all the XY values in a

program to the new location or orientation. This is done using the Program Offset function. For this function to work

properly, follow this procedure to set two Mark Points on the workpiece.

PREREQUISITES

A workpiece is properly positioned on the xture plate.

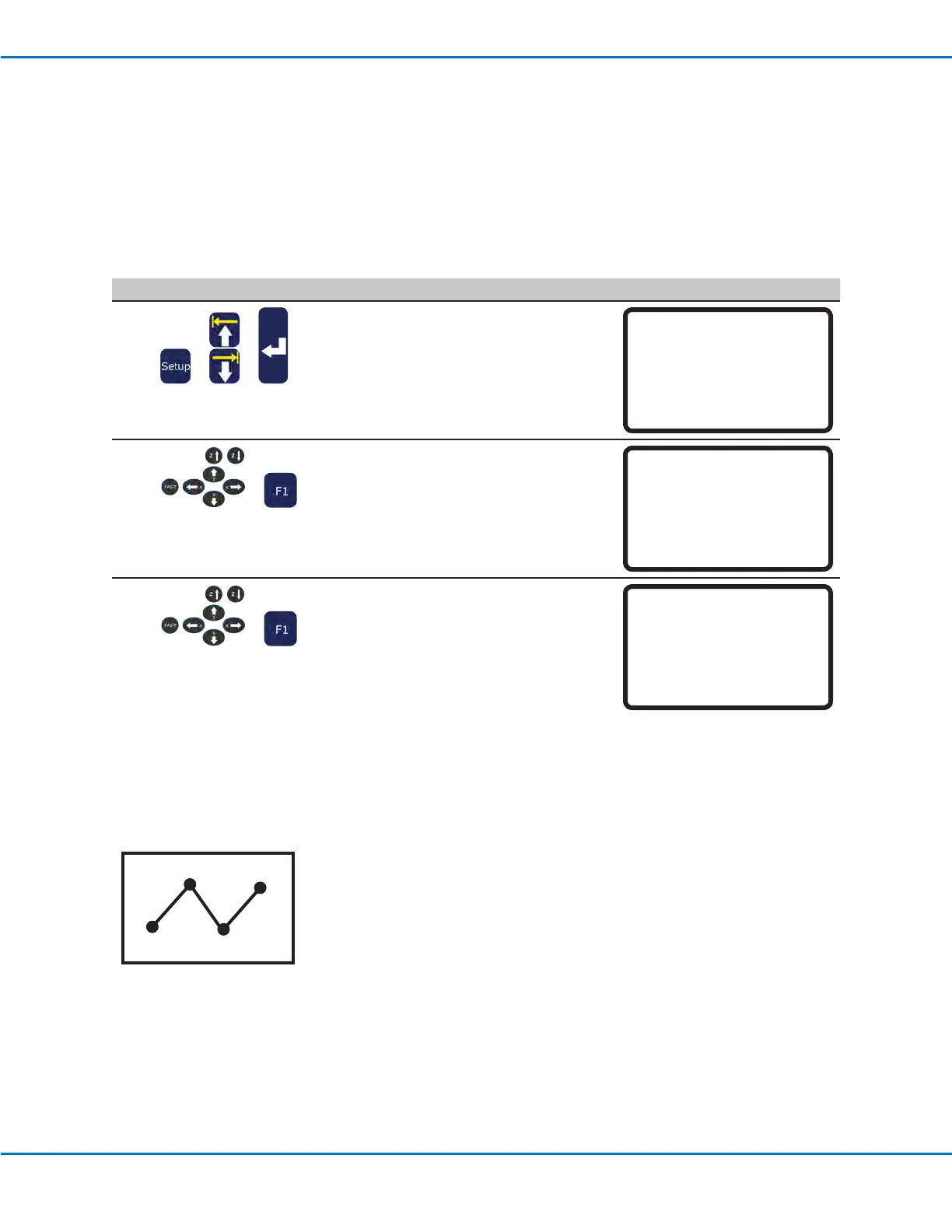

# Key Press Step Teach Pendant Display

1

> >

• Press SETUP.

• MOVE UP / DOWN to MARK POINTS.

• Press ENTER.

[SETUP] 1/3

01 XY Move Speed

02 Z Move Speed

03 Point to Point Arc Jump

04 Park Position

05 Calibration Point

06*Mark Points

07 Program Output Status

2

>

• Jog the tip to the rst mark point and

lower the tip until it is as close to the

mark point as possible.

• Press F1 to save the setting.

Mark Points

------------------------------

Jog tip to Mark Point 1

------------------------------

[F1] OK

3

>

• Jog the tip to the second mark point

and lower the tip until it is as close to

the mark point as possible.

• Press F1 to save the setting.

The system saves the mark points. Now,

if you need to change the position and/

or orientation of a workpiece, you can

use Program Offset (refer to page 53)

to update all the XY locations in the

program to the new workpiece location

and / or orientation.

Mark Points

------------------------------

Jog tip to Mark Point 2

------------------------------

[F1] OK

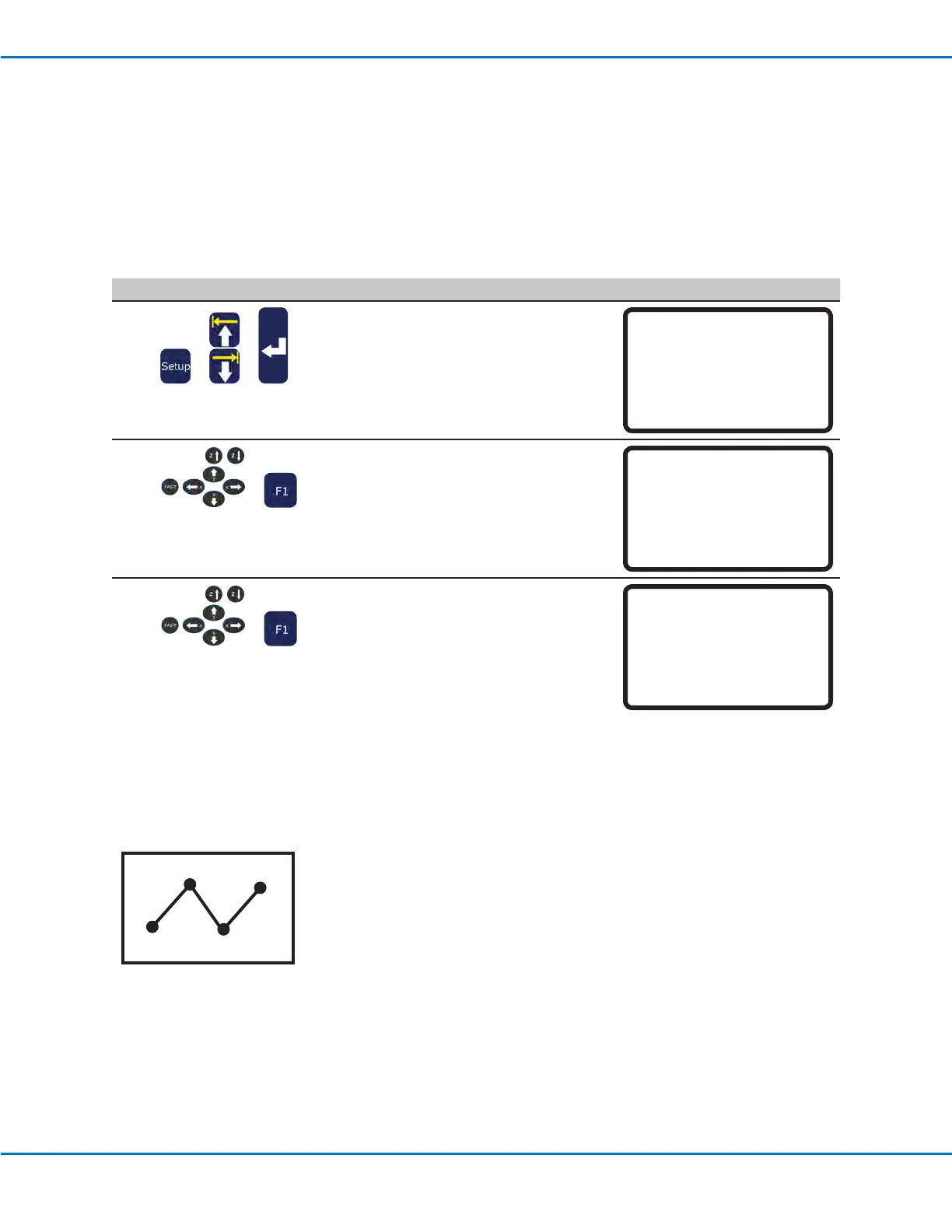

Example of two Mark Point locations on a workpiece

Working with Programs and Commands (continued)

+

+

Mark 1

Mark 2

Loading...

Loading...