E Series Automated Dispensing System

70 www.nordsonefd.com info@nordsonefd.com 800-556-3484 Sales and service of Nordson EFD dispensing systems are available worldwide.

Calibrating the Tip Height

Tip height is the distance from the tip to the xture plate surface. The tip height must be calibrated and then

recalibrated as needed to compensate for slight variations in height that occur when changes are made to the

system, primarily nozzle or tip change-out.

NOTE: For information on when to calibrate the tip height, to “About Tip Height” on page19.

Systems without a Tip Detector

If your system does not include the optional tip detector, follow these procedures to calibrate the tip height and then

to manually recalibrate the tip height after a same-to-same dispensing tip change.

NOTE: The optional tip detector can be added to a existing system. Refer to “Tip Alignment Kit” on page79.

Set a Calibration Point (Initial Setup for Needle Adjust)

The system uses a calibration point for the Needle Adjust function to recalibrate the tip height after a same-to-same

dispensing tip change.

PREREQUISITES

The system is in the Teach Mode. Refer to “How to Switch from Run Mode to Teach Mode” on page44.

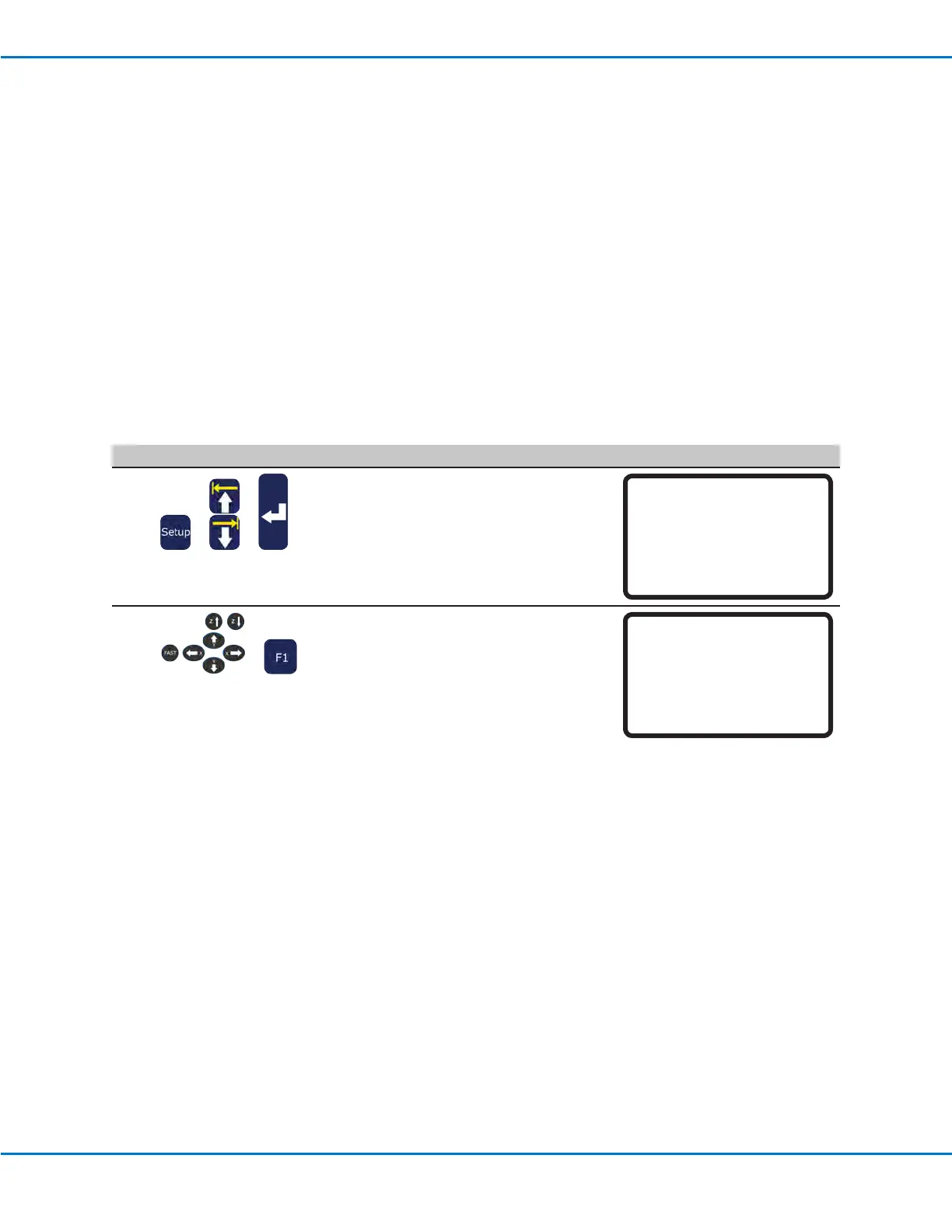

# Key Press Step Teach Pendant Display

1

> >

• Press SETUP.

• MOVE UP / DOWN to CALIBRATION

POINT.

• Press ENTER.

[SETUP] 1/3

01 XY Move Speed

02 Z Move Speed

03 Point to Point Arc Jump

04 Park Position

05*Calibration Point

06 Mark Points

07 Program Output Status

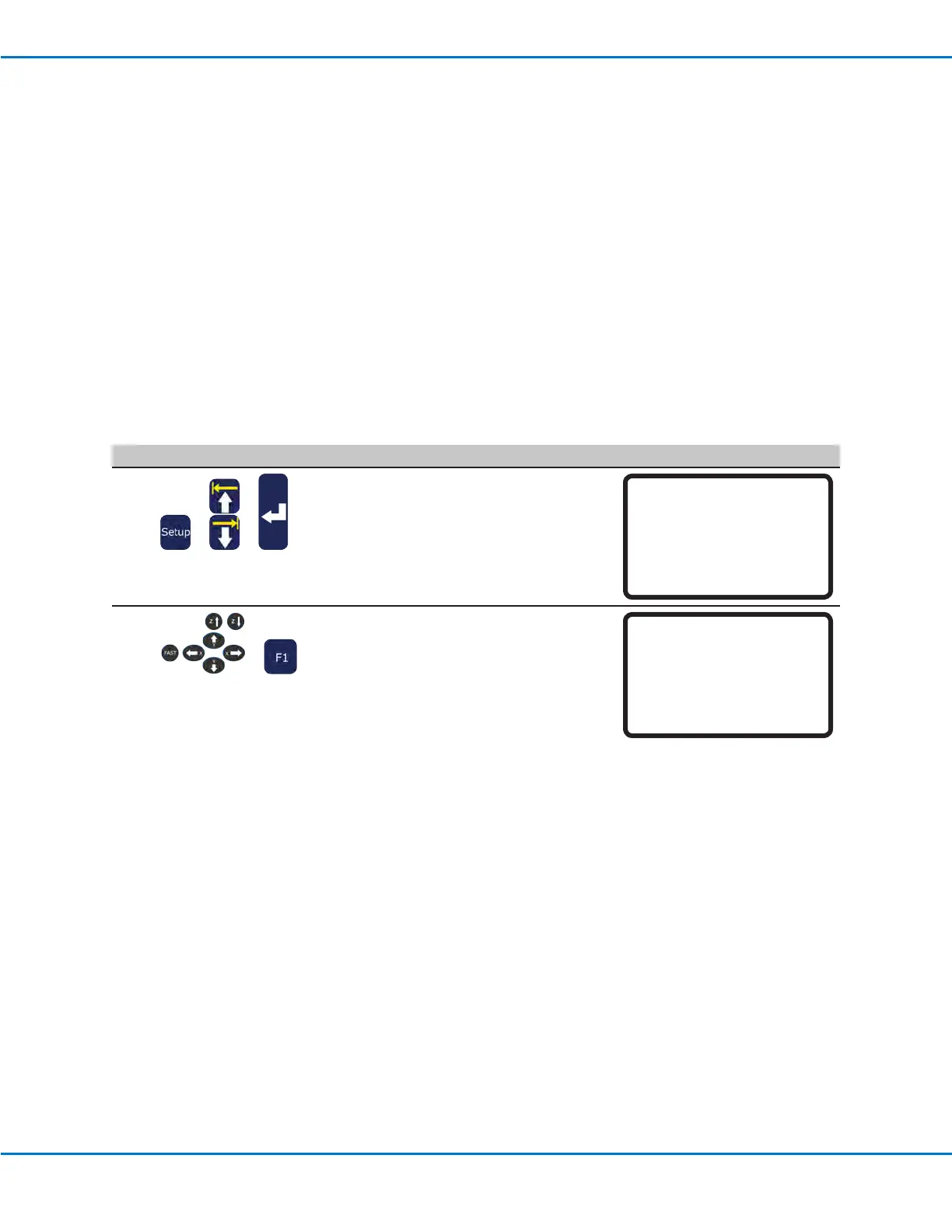

2

>

• Jog the tip down until it is as close to

the xture plate surface as possible.

• Press F1 to save the setting.

Calibration Point

------------------------------

Jog to position

------------------------------

[F1] OK

Loading...

Loading...