Trinity Ts │Installation and Operation Instructions Ts Series

30

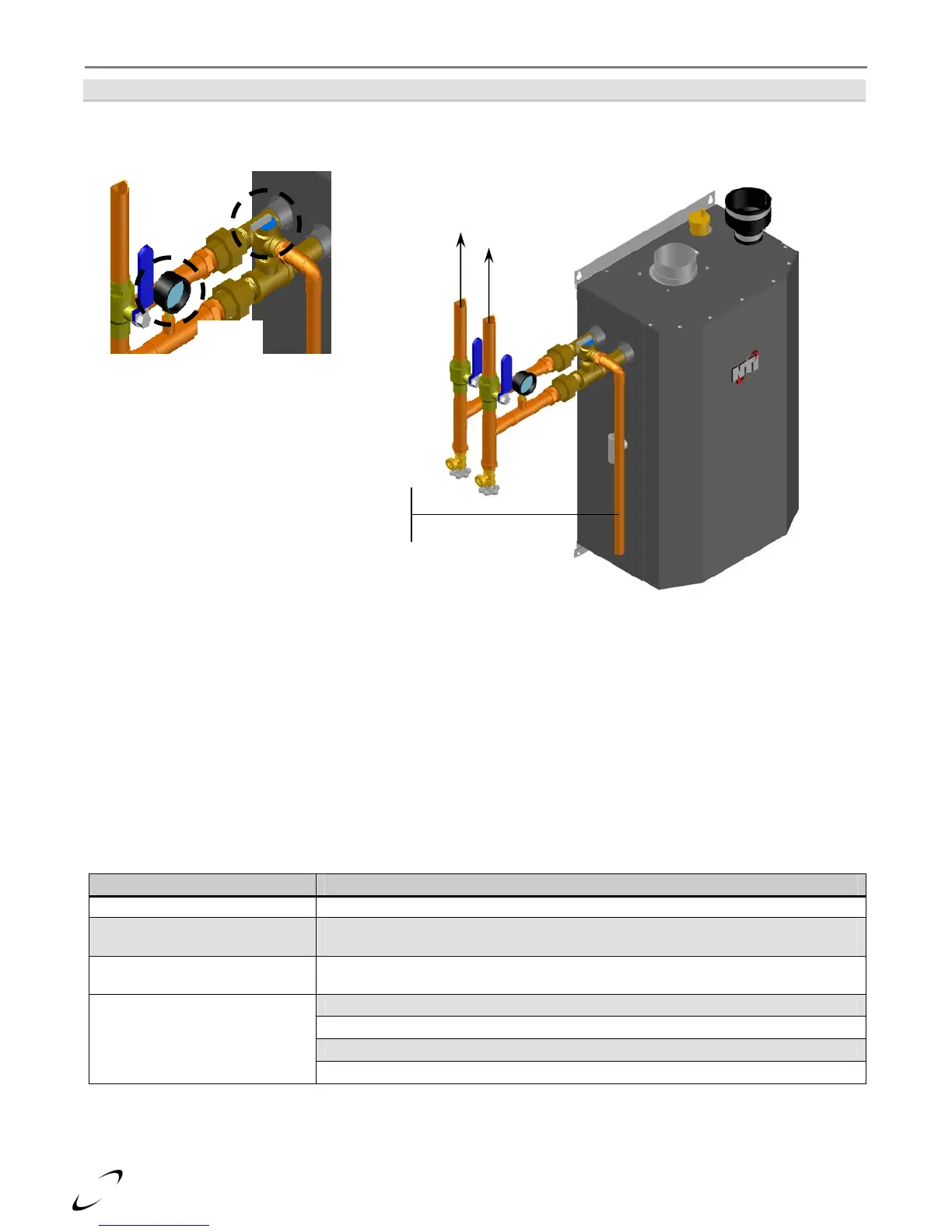

Figure 10-1 Ts80 Model

Near Boiler Piping

Boiler System Plumbing

The Trinity Ts boiler uses a low mass heat exchanger that requires a minimum rate of forced water circulation

any time the burner is operating (See Table 10-4 for minimum flow rates). To ensure the minimum flow rate is

attained, the boiler must be installed in a “Primary/Secondary” plumbing configuration utilizing “Closely Spaced

Tees” to de-couple the Boiler-Primary loop from the System-Secondary loop(s). See the examples of

Primary/Secondary Loop configurations in Figures 10-2 and 10-3.

System Components – As well as a Primary/Secondary Loop Configuration utilizing closely spaced tees a

properly installed system will include the following major components identified in Table 10-3 as a minimum.

Table 10-3 System Major Component Checklist

Factory Supplied Field Supplied Components

Pressure Relief Valve Boiler Loop Circulator (Pump B in Figure 10-2 or Pump C in Figure 10-3)

Pressure Gauge

DHW Loop Circulator (Pump A in Figure 10-2 and Figure 10-3, for applications

utilizing Indirect Fired Water Heater only)

Central Heat (CH) Loop Circulator(s)

(CH Circulator - Pump C in Figure 10-2; Zone Circulators in Figure 10-3)

Central Air Removal Devices (i.e. Micro Bubbler or Air-Scoop)

Pressure Regulating “Fill Valve”

Backflow Preventor

Expansion Tank

Connect to boiler and

system plumbing. Refer

to Figures 10-2 and 10-3.

Inlet

Outlet

Pressure Relief

Valve discharge

to floor drain

Pressure Relief

Valve

Pressure

Gauge

Loading...

Loading...