Ts Series Installation and Operation Instructions │Trinity Ts

55

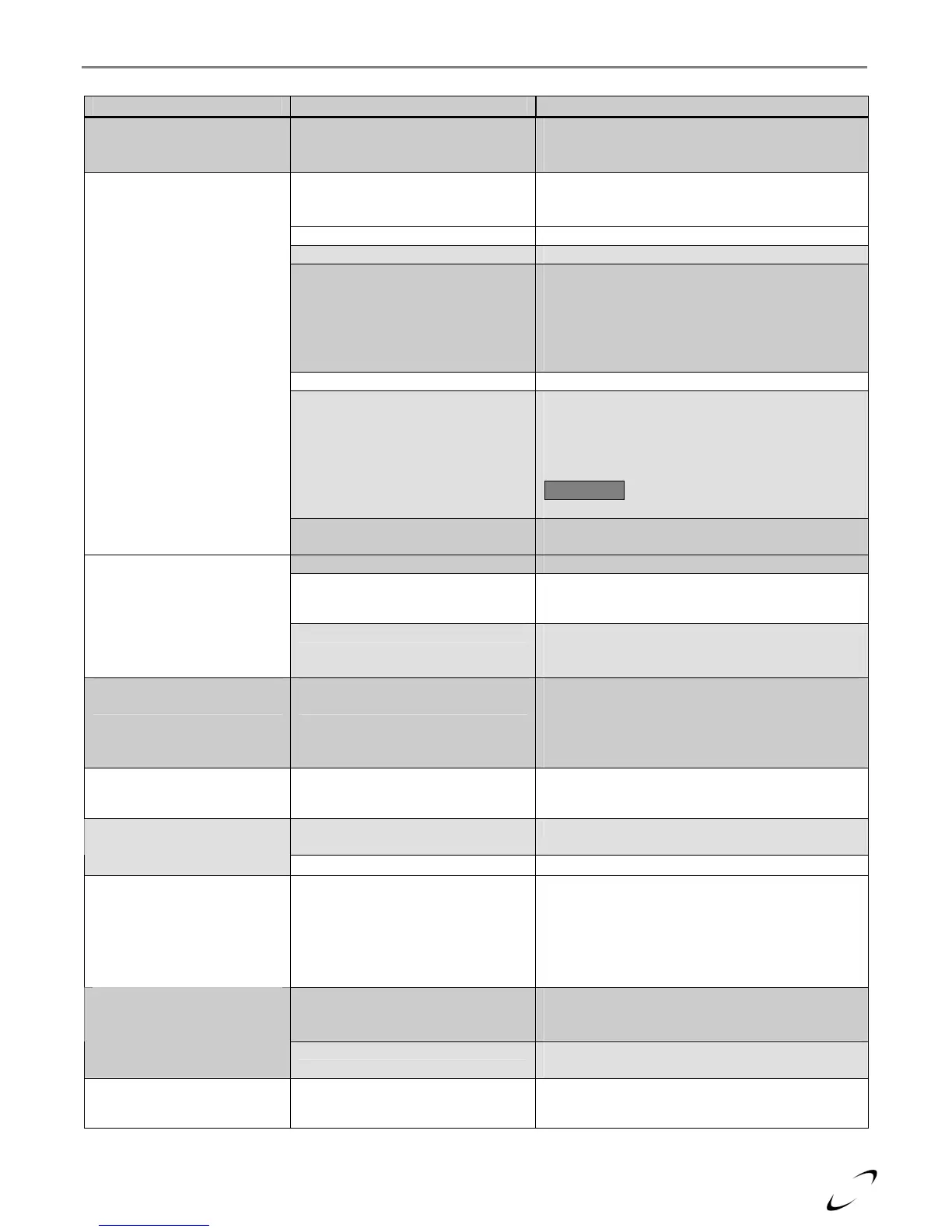

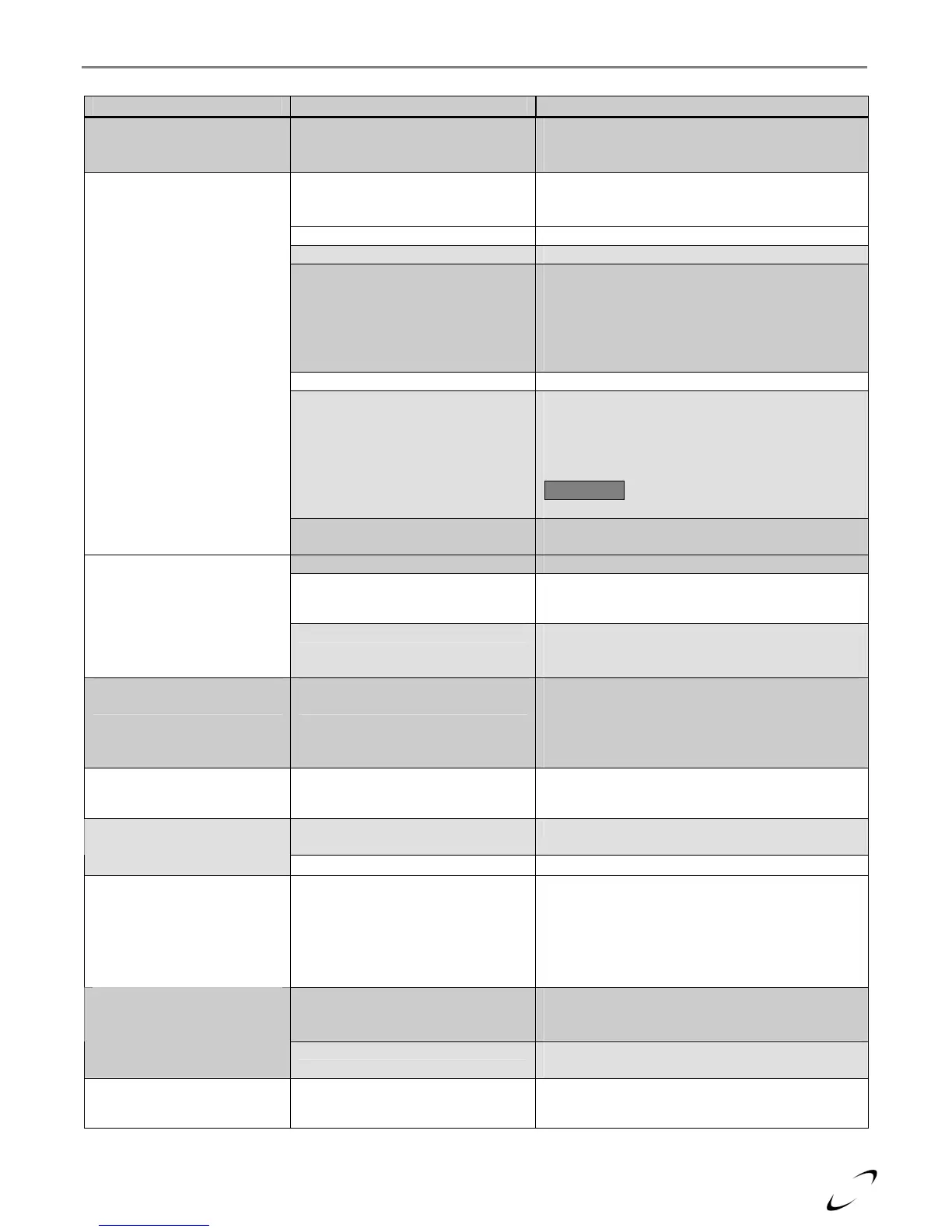

Table 16-1 Troubleshooting Chart

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

Hold 63 – LCI OFF (Limit

control input)

Insufficient water pressure Ensure pressure is at or above 15PSI; if problem

persists after exceeding 20PSI – replace low water

pressure switch (PN:83223-1)

Faulty blower If blower remains off after the lockout is cleared,

check 120VAC supply to blower, if present

replace blower.

Blocked venting Check for blockage of the exhaust vent.

Blocked air inlet Check for blockage of the air inlet.

Disconnected, damaged or blocked

tubing

Inspect the clear vinyl tubing connecting the air

switch + and – ports to the air metering elbow.

Condensation or other foreign matter may be

obstructing the tubing, preventing the switch from

sensing differential pressure caused by air flow

through the metering elbow.

Incorrect air switch setting Contact NTI technical support.

Faulty air switch If venting and air inlet are clear, temporarily

jumper the air switch. If the unit lights and

operates smoothly – replace air switch. If the unit

fails to light or lights but runs rough or abruptly

shuts down – check boiler internals for blockage.

WARNING Only jumper the air switch for

diagnosing purposes.

Lockout 65 – Interrupted Air

Switch OFF

Incorrect air switch wiring Check that the red and orange wires are connected

to quick connect tabs 3 and 1 respectively.

Incorrect air switch setting Contact NTI technical support.

Incorrect air switch wiring Check that the red and orange wires are connected

to quick connect tabs 3 and 1 respectively.

Hold 66 – Interrupted air

switch ON (and blower is off)

Faulty air switch Disconnect red and orange wires from air switch

and check for open circuit between terminals 1 &

3. If continuity detected, replace air switch.

Hold 66 – Interrupted air

switch ON (and blower is on)

- Blower problem

- Faulty controller

Check low voltage wiring from blower to

controller. Check VDC signal from red–green

and black-green; if not 28-32VDC and 0 VDC

respectfully – replace controller. If signal is

correct – replace blower.

Lockout 67 – ILK OFF External Limit Tripped Indication that an external limit (wired to “LIM”)

had opened. Not a problem with boiler.

High Central Heat or DHW set

point.

Reduce Central Heat and DHW set points. Hold 79 – Outlet High Limit

Insufficient water flow or pressure

See

lockout 81 below.

Lockout 81 – Delta T limit

OR

Boiler making banging or

hissing sounds

Insufficient water flow

• Check boiler pump.

• Ensure plumbing is correct. Check that water

pressure is at least 15PSI.

• Boiler heat transfer surfaces may be fouled

with scale or magnetite. Clean with Fernox

DS-40 Descaler and Cleanser. See Table 10-1.

Dirty heat exchanger Inspect and if required clean the combustion

chamber and/or heat exchanger. Refer to Section

15.0 Annual Maintenance and Inspection.

Lockout 82 – Stack limit

Faulty sensor Check resistance of stack sensor and compare to

thermistor resistance chart, see Table 16-2.

Lockout 85 – Inlet/Outlet

Inversion Limit

Pump flowing in the wrong

direction

Ensure water circulation is flowing into the boiler

at the fitting closest to the wall.

Loading...

Loading...