General Venting │ Vmax I&O Manual

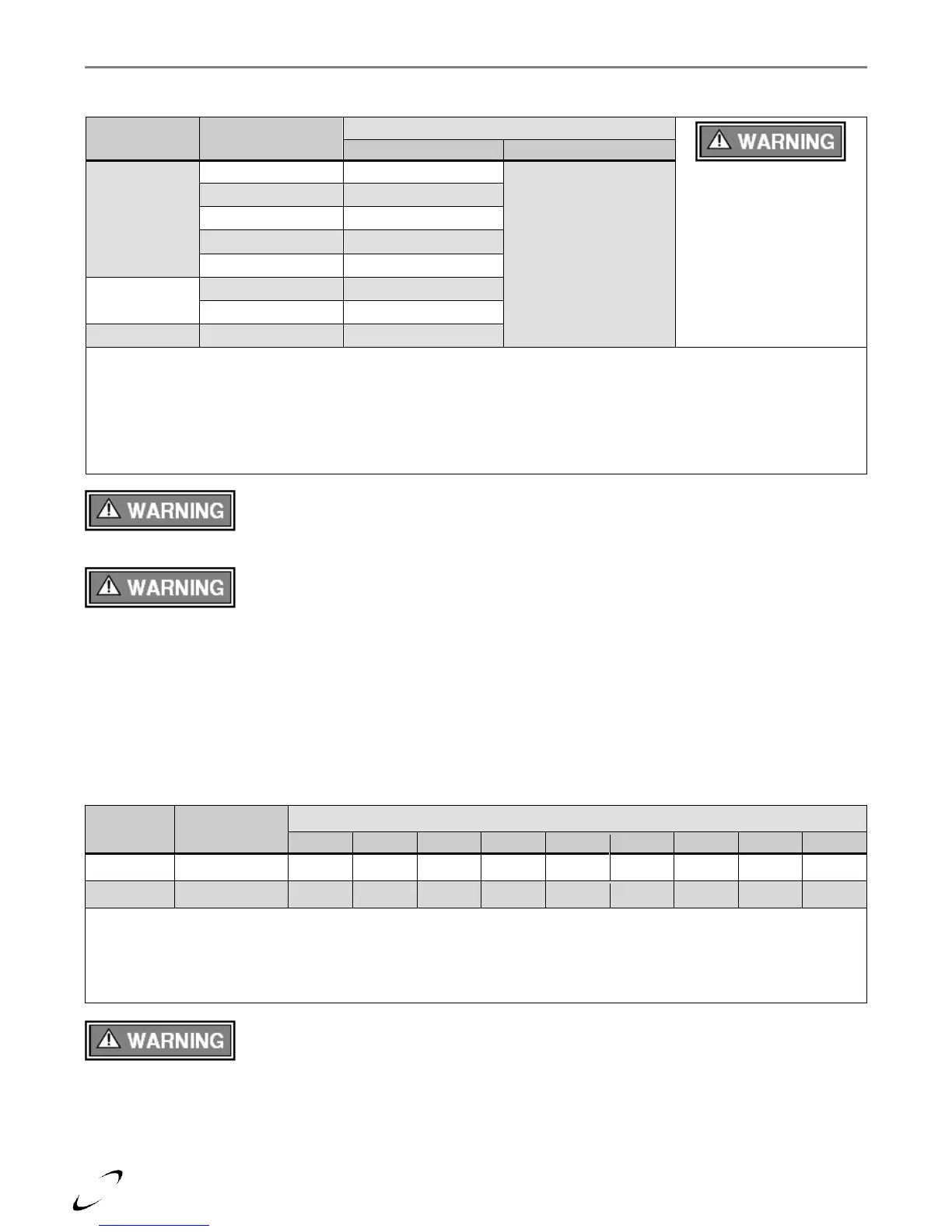

Vent/Air-inlet Pipe Material

Table 4-2 Approved Vent and Air-Inlet Pipe Material

All Vent and Air-Inlet

materials installed on gas

fired appliances in CAN/US

must meet the Standards

listed in this Table. Failure

to comply could result in

fire, serious injury or death.

All venting material in

Canada must be

ULC S636 approved.

See Note 4 below for

appropriate temperature

applications.

Notes:

1

Refer to Table 4-5 for Allowable Vent and Air-inlet Pipe Sizes and Lengths.

2

PVC venting (exhaust and air-inlet) is not permitted within the Closet/alcove of a Closet/alcove installation.

3

The Air-inlet does not require high temperature pipe material. Check applicable local codes for acceptable materials.

4

ULC S636 PVC is approved for flue gas temperatures up to 149

o

F (65

o

C) and must only be used for low temperature

applications. High temperature applications requiring boiler supply water temperatures greater than 140

o

F (60

o

C) must

use ULC S636 CPVC, PP or SS.

The use of cellular core PVC (ASTM F891), cellular core CPVC, or Radel®

(polyphenolsulfone) in the exhaust venting system is prohibited. Failure to follow these

instructions may result in property damage, personal injury or death.

Covering non-metallic vent pipe and fittings with thermal insulation is prohibited. Failure

to follow these instructions may result in property damage, personal injury or death.

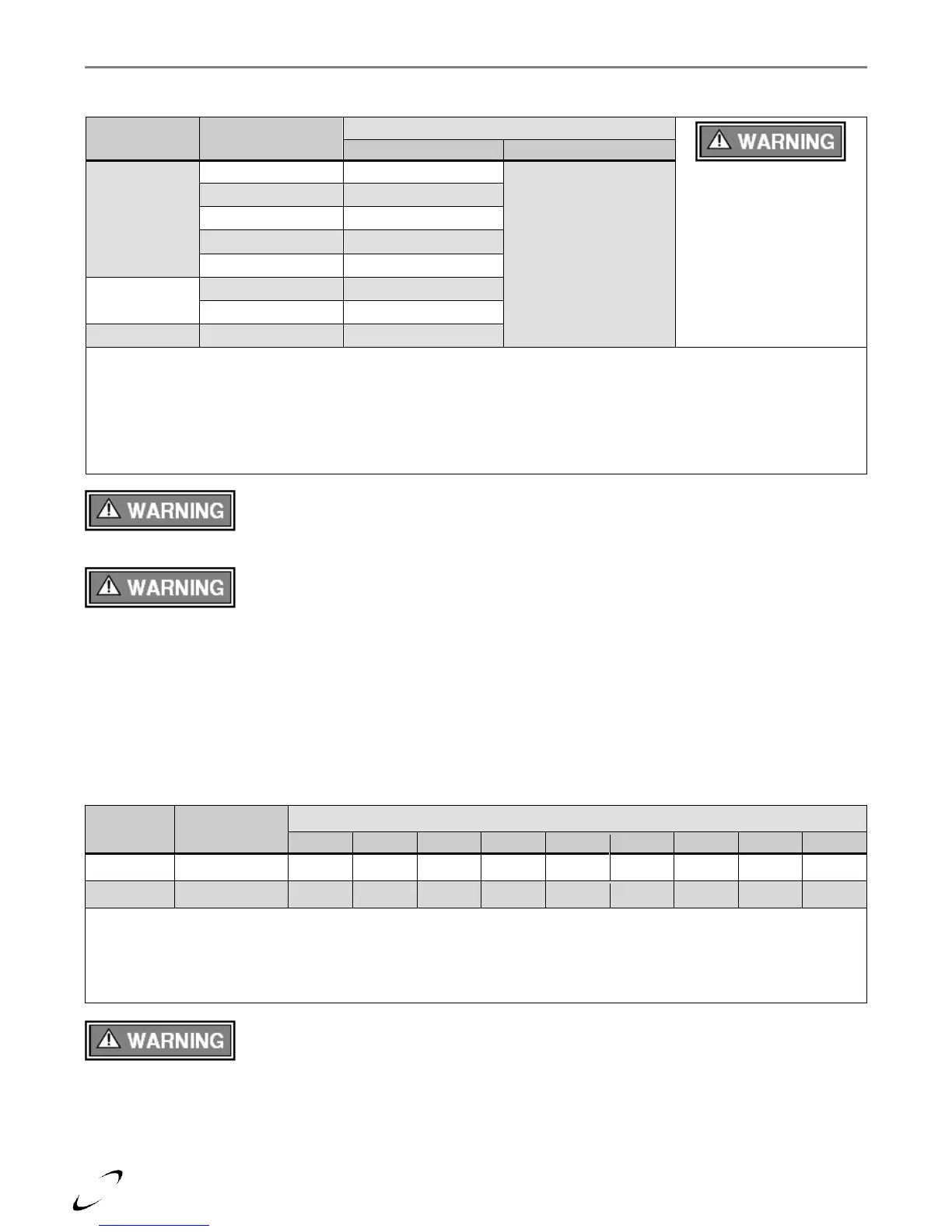

Vent/Air-inlet Pipe Length Determination

Use Table 4-3 to determine the maximum pipe length that can be used. The table calculates 90º elbows, and 45º

elbows at 5 equivalent feet each.

Example: When using 3 in. pipe, the Vmax can be installed with 150 equivalent feet of air-inlet piping and 150

equivalent feet of exhaust-vent piping. See Table 4-3 for more details.

Table 4-3 Allowable Vent and Air-inlet Pipe Size and Lengths

Number of Elbows (90’s or 45’s) and Equivalent Feet

Note:

1

See WARNING below.

2

Minimum length of each the exhaust vent and combustion air-inlet piping is 5 feet equivalent.

3

When using 2 in., the combustion air-inlet piping must not exceed the length of the exhaust vent piping by more than 25

equivalent feet.

PVC Exhaust Venting – When using 2 inch PVC venting, the first seven (7) equivalent

feet of exhaust venting must be approved 2 inch CPVC or 3 inch PVC; see exceptions in

Table 4-2.

Loading...

Loading...