Field Wiring │ Vmax I&O Manual

Treatment - Boiler water that falls outside of the conditions listed above must be treated with a corrosion

inhibitor. For information on performing the treatment, follow the instructions included with the corrosion

inhibitor. See Table 10-1 for a list of recommended boiler system cleaners and corrosion inhibitors.

To maintain protection, the level of corrosion inhibitor must be monitored periodically

for the correct concentration.

Anti-freeze - For systems requiring freeze protection, use only inhibited propylene glycol, specially formulated

for hydronic heating systems; use of other types of antifreeze may be harmful to the system and will void the

warranty. Note: the use of glycol may reduce the usable output capacity of the boiler, thus requiring the unit

to be “down-fired” by limiting the maximum operating capacity and/or the maximum water temperature. NTI

recommends against exceeding 35% concentration of glycol.

DO NOT use inhibited glycol with non-compatible boiler inhibitors. Non-compatible

inhibitors may counteract each other rendering them ineffective.

Near Boiler Plumbing (Central Heating)

Pressure Relief Valve - A Pressure Relief Valve is factory supplied with each unit. Vmax VM110 and VM110P

boilers have a maximum allowable operating pressure of 30 PSI. The pressure relief valve must be installed

in the vertical position, as illustrated in Figures 10-1, 10-2(a), 10-2(b) and 10-3(a), with the drain pipe outlet

exiting the side of the pressure relief valve horizontally. Pipe the outlet of the relief valve towards the floor,

away from where it could be harmful.

If installed in the incorrect orientation (horizontally with drain pipe out the bottom) the

relief valve may not function properly resulting in property damage or personal injury.

Ensure the discharge of the pressure relief is piped to a location where the steam or water

will not cause property damage or serious injury.

Pressure Gauge – Vmax VM110 and VM110P units come with a factory supplied 60 PSI Pressure Gauge. The

pressure gauge must be installed at the boiler outlet prior to any circulators. See Figures 10-2(c) and 10-3(b).

Low Water Cutoff (LWCO) – Vmax boilers are provided with a factory installed Water Pressure Sensor. The

sensor provides a reading of the boiler inlet water pressure on the display; in the event the pressure drops

below 7 PSI, the control will go to a blocking error “FILL”, inhibiting burner operation. Where required by

the Authority having jurisdiction, an external LWCO may have to be installed; see Figure 10-1.

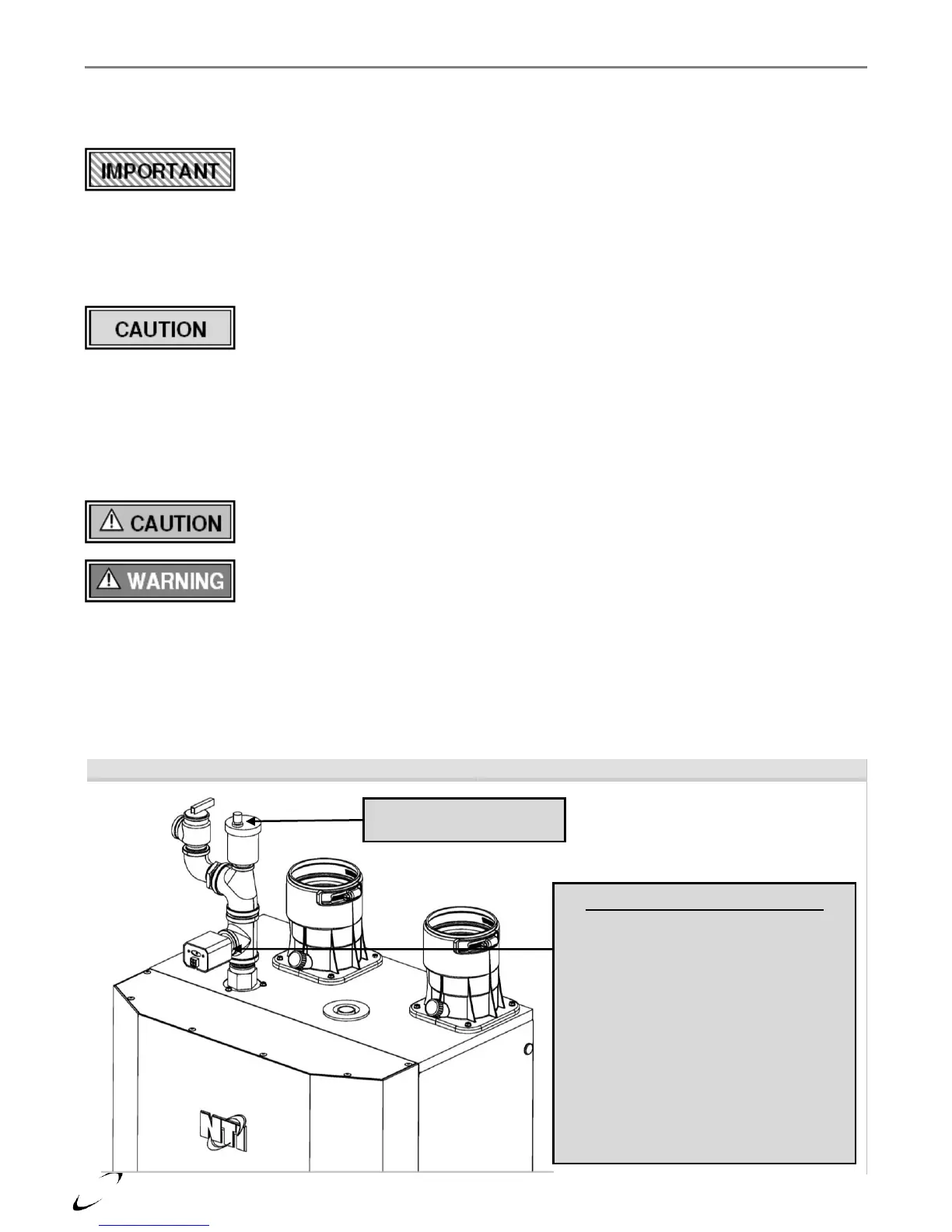

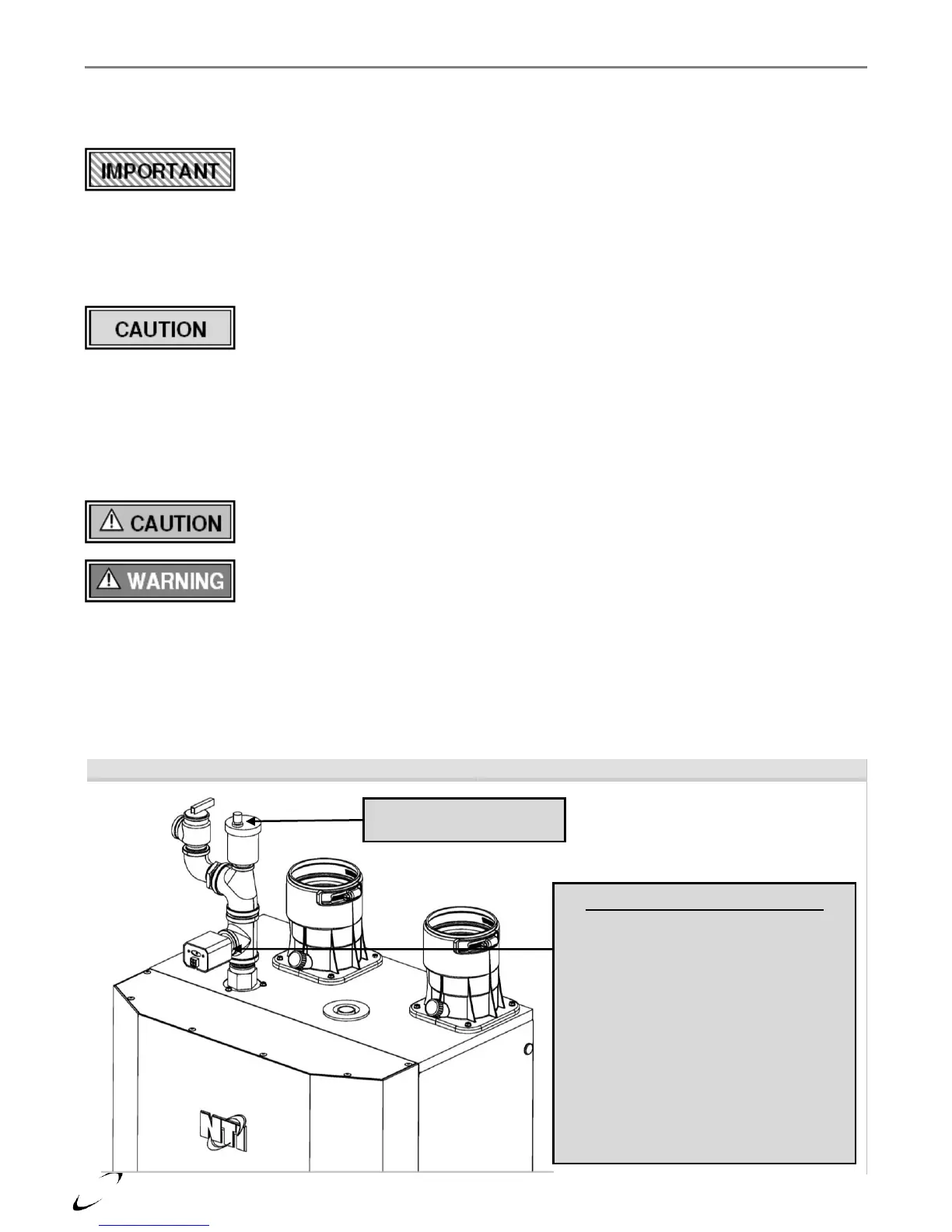

Figure 10-1 Installation of Optional LWCO

Low Water Cutoff Location

(when required by local authorities)

Install the LWCO in a suitable tee (reference

installation instructions provided with the

LWCO) as illustrated. DO NOT install

isolation valves between the boiler and the

LWCO. The LWCO switch must be wired to

break the boiler limit circuit or line power to

the boiler (see Section 12.0 – Field Wiring).

NTI offers the following LWCO kits:

VM110 LWCO Kit – P/N TBD

VM110P LWCO Kit – P/N TBD

When the installation is complete, TEST

THE LWCO to ensure the burner shuts

down when the water level drops.

Auto Air Vent – keep open to

avoid false trips of the LWCO

Loading...

Loading...