HeatWater.com | WaterService@nyle.com | (800) 777-6953 IM-e360-122023 IM-e360-122023 HeatWater.com | WaterService@nyle.com | (800) 777-6953

33

Pre-Startup Checklist

Please review and ensure the following checklist is

complete and veried BEFORE starting up your heat

pump’s compressor for the rst time.

CAUTION

Heat pump startups may only occur with a factory autho-

rized commissioning agent. Do not start the heat pump

before the authorized agent is on site and ready to assist.

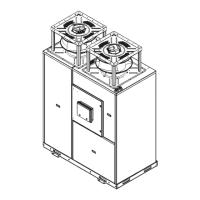

Placement and Physical Checks

F Unit is level, stable, and securely mounted.

F Unit has all appropriate service clearances,

and access panels are not obstructed by pipes,

wires, or other obstacles.

F Unit is adequately protected from falling objects,

vehicles, or other potential damage.

F Fans are securely mounted and wired to the unit.

F Loosen nuts on the compressor feet to remove

the slotted washers, and leave the nuts loose.

F Open the heat pump and inspect the cabinet around

the refrigeration piping and compressor for any

signs of leaks or oil. If any signs of refrigerant leak

are present, DO NOT START THE UNIT. Leaks

need to be identied and xed, and refrigerant

charge weighed, before startup can occur safely.

F Perform a tug test on all wires in the electrical

enclosure, to ensure all wires remain rmly seat-

ed after shipping. Ensure all power feeds are

powered down for this testing.

CAUTION

Damage to the compressor due to startup with visible

leak indication is not covered by warranty.

Air and Ducting Checks

F Ducting, cowl, or plenums are secured to the

unit, sealed, and insulated as appropriate.

F Ducting, if present, is complete, insulated, and

connected to terminal grilles/louvers.

F Exterior louvers and connecting ductwork will

limit moisture intrusion, and drain in or out for

what moisture does intrude.

Water and Piping Checks

F Exterior water piping is insulated, freeze protect-

ed, pitched toward drain points.

F All water piping has been pressure tested and

veried leak free.

F All water piping has been lled with water and

actively purged of air.

F Pressure relief valves are piped to the oor,

drain, or reservoir as per local codes.

F Water quality has been determined to be ac-

ceptable for operation and potable use.

F Verify tank temperature probe, if present, is installed

10-12" minimum above cold water inlet in primary

storage tank, and has at least the minimum cycle

volume between it and the heat pump’s inlet pipe.

Condensate Management Checks

F Exterior condensate piping is insulated, freeze

protected, pitched toward drain points.

F Pour several gallons of water slowly into the

condensate pan, and verify the drain is clear

and operational.

F Condensate pump, if used, is plugged in and

operational.

Electrical Checks

F Main power and 120V power wires are securely

attached to the heat pump and active.

F All control and communication wires are se-

curely attached, and connected equipment is in

place and ready to operate.

F Verify remote outdoor air sensor (ducted sys-

tems only) is installed in a location without sig-

nicant heat gains from intermittent sources and

is near the heat pump intake air louver.

Final Checks

F All panels and enclosures are securely closed

and afxed.

F All ball valves in the piping systems are open,

including valves on expansion tanks, storage

tanks, condensate drains and swing tanks.

F Ensure that the Startup Procedure in the follow-

ing manual section is on hand for the commis-

sioning agent to ll out during startup. PDFs are

available for download through your manufac-

turer’s representative or using the QR Code in

the “Startup Procedure” portion of this manual.

F Turn on main and 120V power to allow the heat

pump to warm up. DO NOT engage any func-

tions on the control interface.

Loading...

Loading...