HeatWater.com | WaterService@nyle.com | (800) 777-6953 IM-e360-122023 IM-e360-122023 HeatWater.com | WaterService@nyle.com | (800) 777-6953

23

Power Wiring

WARNING

Improper handling of unit electrical power can result in im-

mediate equipment damage, res, injury, and death. Ensure

only qualied personnel interact with main power lines. Nev-

er work while power is live; use all possible safety precau-

tions and perform all work in accordance with appropriate

local codes, National Electric Code, and/or CSA regulations.

Heat pump water heaters are voltage-specic, and re-

quire proper planning to provide the electrical support

appropriate to each unit. Refer to the electrical speci-

cations, specic product submittals, project documen-

tation, and the requirements and the following instal-

lation instructions.

e-Series units expect to have two separate power

feeds from the building: a main power feed, and a

smaller 120V power feed intended to be connected to

an electrical source with generator backup for freeze

protection during power outages.

If the unit will not be installed in freezing conditions,

and/or if the main power feed is itself on a generator,

an optional Unied Power Package accessory can be

ordered for 460V or 230V main power to consolidate

the two power feeds into a single point feed from the

building. It is very important that power outages and

freeze protection be considered in the power plan.

Unied Power Package instructions and wiring are in-

cluded in that accessory’s documentation.

208V main power feeds can be wired to provide uni-

ed power without a separate accessory. This requires

an additional neutral conductor and minor additional

wiring in the unit. See the following instructions and

Diagram 3 on page 25.

Power Requirements

1. Voltage is correct to within +/- 5% of ratings and

within +/-2% between phases.

2. Power is clean, reliable, and well grounded.

3. Wire and breakers are appropriately sized for the load.

4. Wire and breakers are properly specied for the en-

vironment they are installed in.

5. Backup generators should include line conditioning

suitable for running electronics.

6. Follow manufacturer’s torque specications for all

power wire equipment by others.

7. Install service disconnects on incoming power feeds

at the heat pump location.

8. All power wiring to the unit must be rated for 600V.

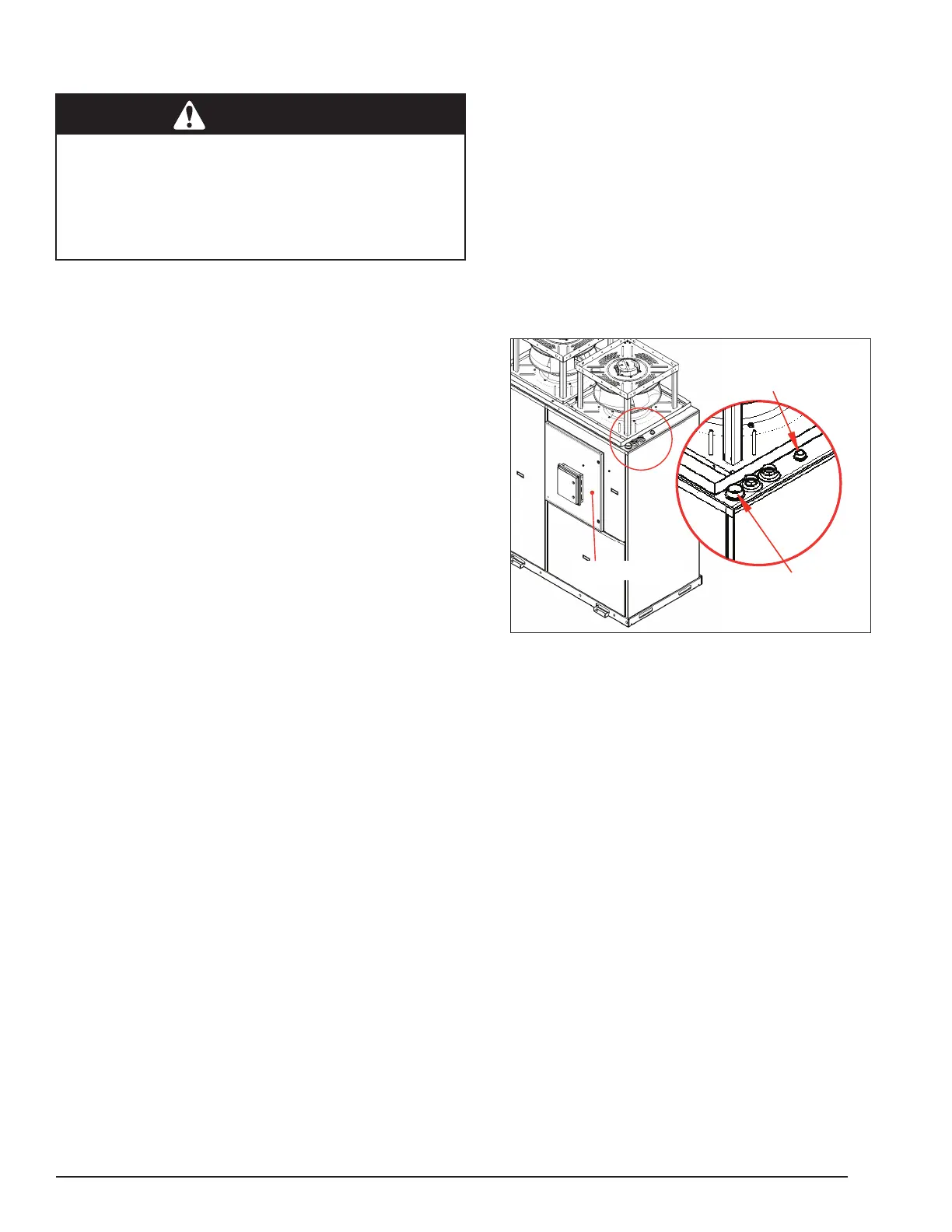

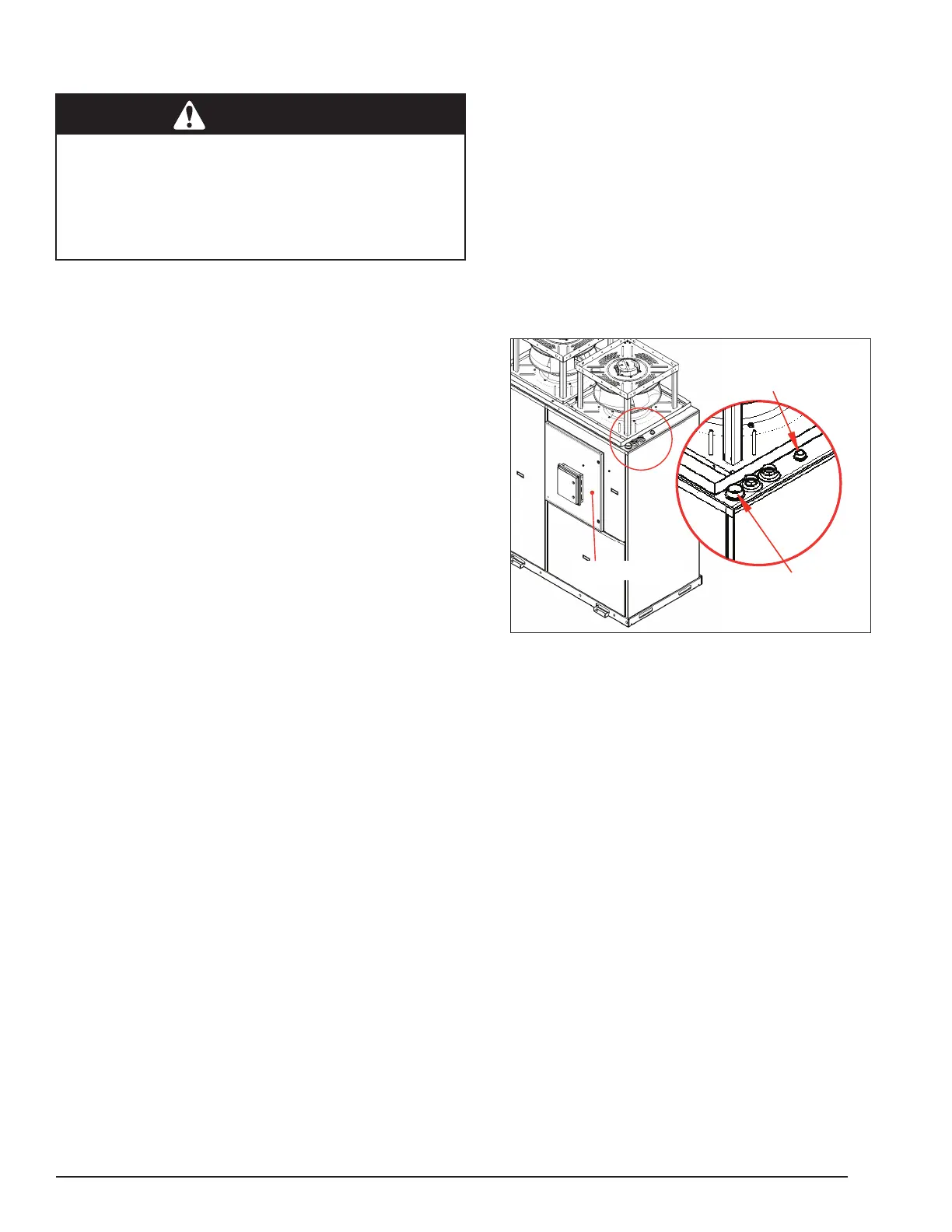

The e-Series heat pump has an incoming power feed

conduit from the interior electrical enclosure to a termi-

nation point on the top of the unit. This conduit ships with

a termination plug that will need to be removed to access

the conduit. Main and 120V power feeds will run through

the same conduit. A second, smaller conduit is used for

control wires. See Figure 13.

To Install the Power Wires

1. Identify the power entry conduit in the top of the heat

pump (Figure 13). Remove the shipping plug to ac-

cess the conduit.

Figure 13: Conduit Power Entry Locations

Power Entry Conduit

Control Entry Conduit

Electrical Enclosure

2. Open the electrical enclosure box

3. Run incoming power conduit(s) to the heat pump

termination tting. Leave sufcient exposed wire to

sh into the heat pump conduit. Be sure the wire is

sized for the load, or as dictated by local codes and

conditions, whichever is larger.

4. Route the incoming power wires through the conduit

into the enclosure box providing excess length to

reach the appropriate terminals. This conduit includes

a midpoint access to facilitate wiring installation.

5. Finish exterior conduit connection to the unit using

a weather tight connection method. Conduits termi-

nate in female thread.

6. Connect power wires to their terminals. Refer to ”Di-

agram 2: Power Wiring Connections” on page 24

Use 375 foot-pounds of torque on the heat pump’s

connection terminals. All power distribution terminals

are located in the upper right corner of the electrical

enclosure.

7. Close the electrical enclosure box.

Loading...

Loading...