Operating & Maintaining the Connex500/350 3-D Printer

7–18

DOC-13000 Rev. E

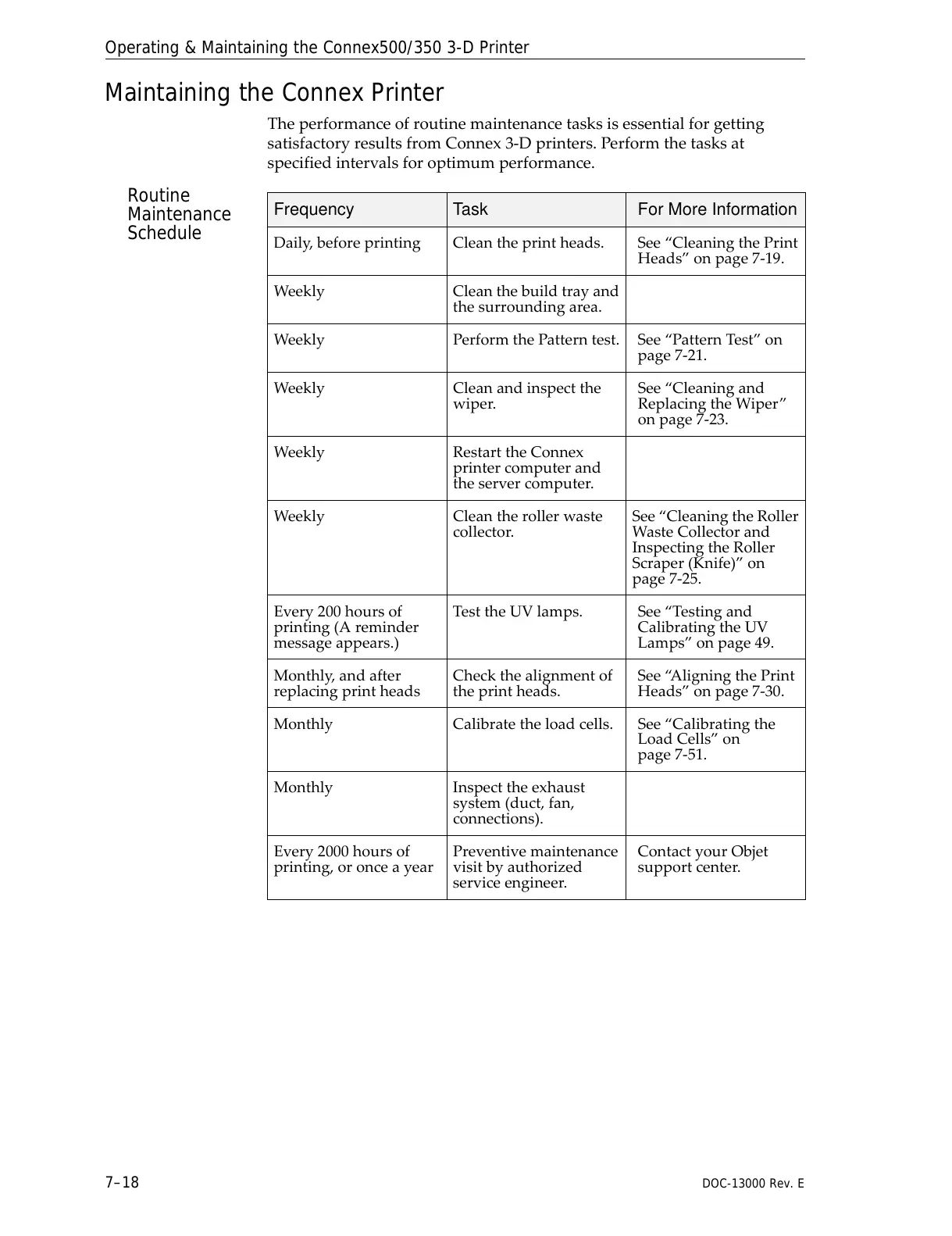

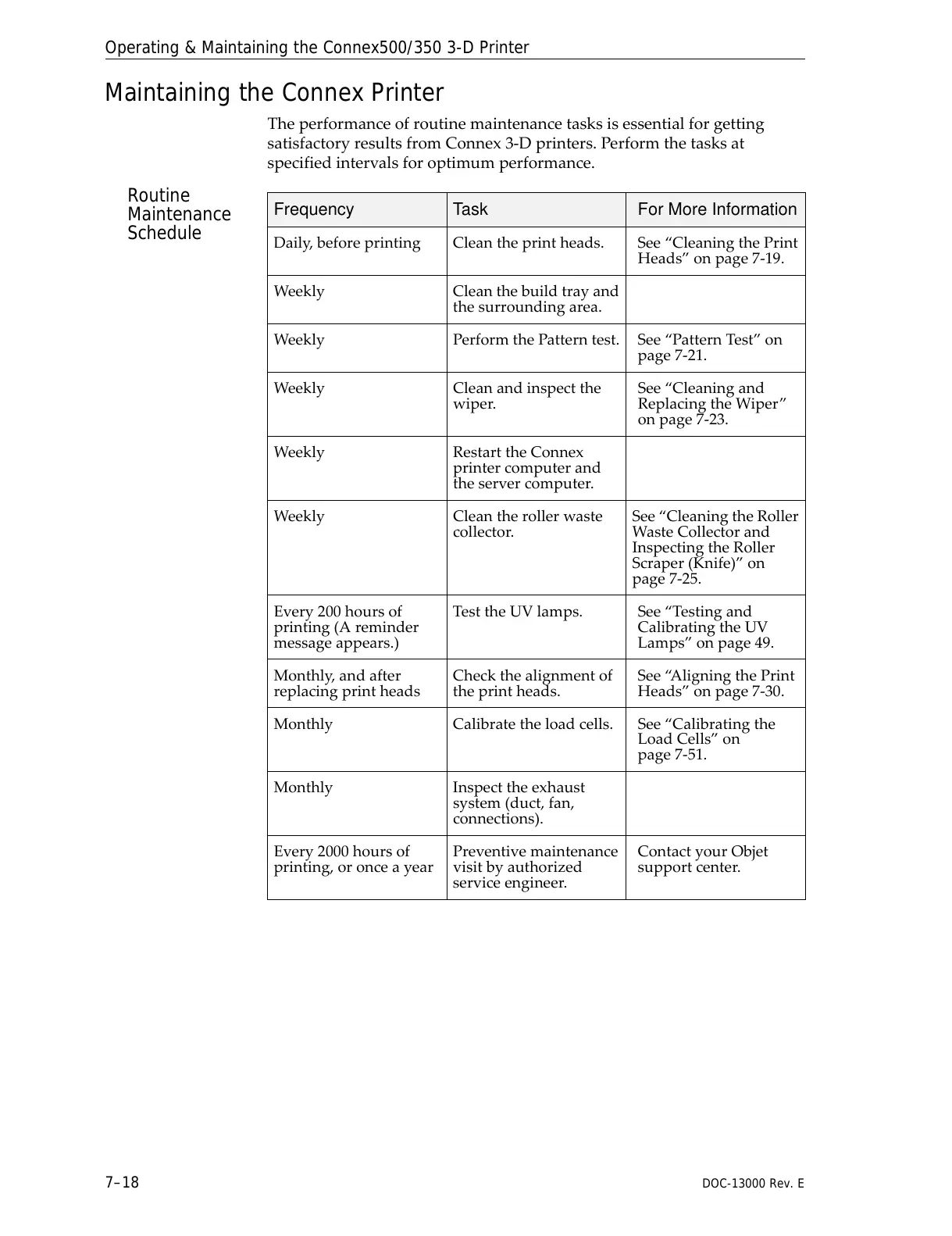

Maintaining the Connex Printer

Theperformanceofroutinemaintenancetasksisessentialforgetting

satisfactoryresultsfromConnex3‐Dprinters.Performthetasksat

specifiedintervalsforoptimumperformance.

Routine

Maintenance

Schedule

Frequency Task For More Information

Daily,beforeprinting Cleantheprintheads. See“CleaningthePrint

Heads”onpage 7‐19.

Weekly Cleanthebuildtrayand

thesurroundingarea.

Weekly PerformthePatterntest. See“PatternTest”on

page 7‐21.

Weekly Cleanandinspectthe

wiper.

See“Cleaningand

ReplacingtheWiper”

onpage 7‐23.

Weekly RestarttheConnex

printercomputerand

theservercomputer.

W

eekly Cleantherollerwaste

collector.

See“CleaningtheRoller

WasteCollectorand

InspectingtheRoller

Scraper(Knife)”on

page 7‐25.

Every200hoursof

printing(Areminder

messageappears.)

TesttheUVlamps. See“Testingand

CalibratingtheUV

Lamps”onpage 49.

Monthly,andafter

replacingprintheads

Checkthealignmentof

theprintheads.

See“

Aligningthe Print

Heads”onpage 7‐30.

Monthly Calibratetheloadcells. See“Calibratingthe

LoadCells”on

page 7‐51.

Monthly Inspecttheexhaust

system(duct,fan,

connections).

Every2000hoursof

printing,oronceayear

Preventivemaintenance

visitbyauthorized

serviceengineer.

ContactyourObjet

supportcenter.

Loading...

Loading...