D6F-series MEMS Flaw Sensor User’s Manual (A286) 4

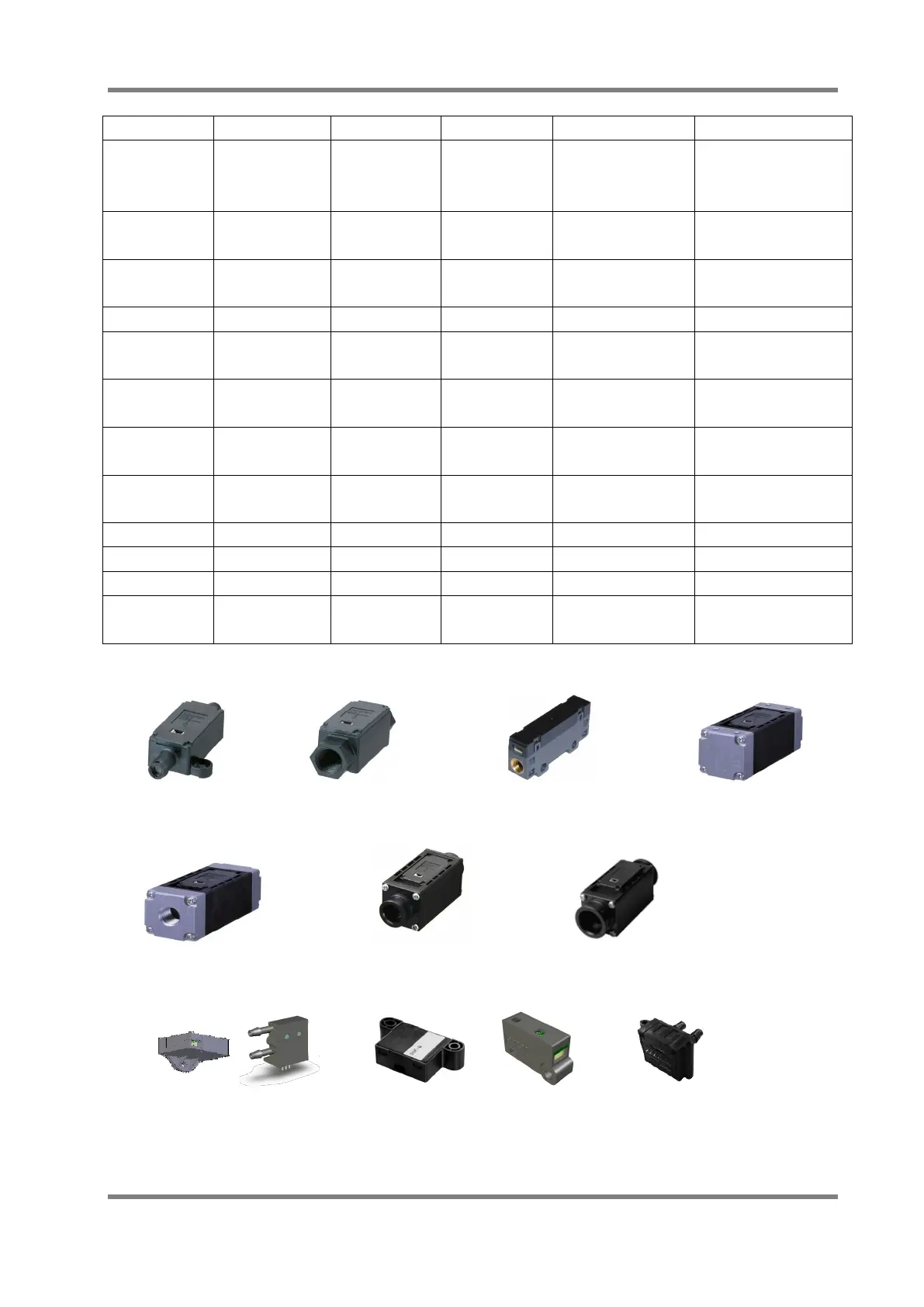

Table 2 Outline Specifications of D6F series

Series Name

Flow Rate Type Port Style Features

D6F-□A1 Air 1 ~ 2 lpm Mass Flow Bamboo Joint Compact Size

High Precision

Low Flow Rate

D6F-□N2 City gas*1 1 ~ 5 lpm Mass Flow Rc1/4 Screw Flammable Gas

Metal Body

D6F-02L2 LPG 2 lpm Mass Flow Rc1/4Screw Flammable Gas

Metal Body

D6F-03A Air 3 lpm Mass Flow M5 Screw High Response Time

D6F-□A5 Air 10 ~ 50 lpm Mass Flow Manifold Compact Size

High Flow Rate

D6F-□A6□ Air 10 ~ 50 lpm Mass Flow Rc1/4 Screw

NPT1/8 Screw

Compact Size

High Flow Rate

D6F-□□7 City gas*1

LPG / Air

2 ~ 50 lpm Mass Flow Quick Joint (P10) Quick Joint

D6F-□AB71 Air 30 ~ 70 lpm Mass Flow Quick Joint (P14) Quick Joint

Pulsation Reduction

D6F-P Air 0.1 ~ 1 lpm Mass Flow Bamboo / Manifold DSS*2 / Bidirectional

D6F-W Air 1 ~ 10 m/s Flow Velocity - DSS*2

D6F-V03A1 Air 3 m/s Flow Velocity - Low Cost of D6F-W

D6F-PH Air ±500 Pa Differential

Pressure

Bamboo Joint

Digital Output

Differential Pressure

Note. *1 : City Gas (Natural Gas) Standard:13A, *2 : DSS: Dust Segregation System

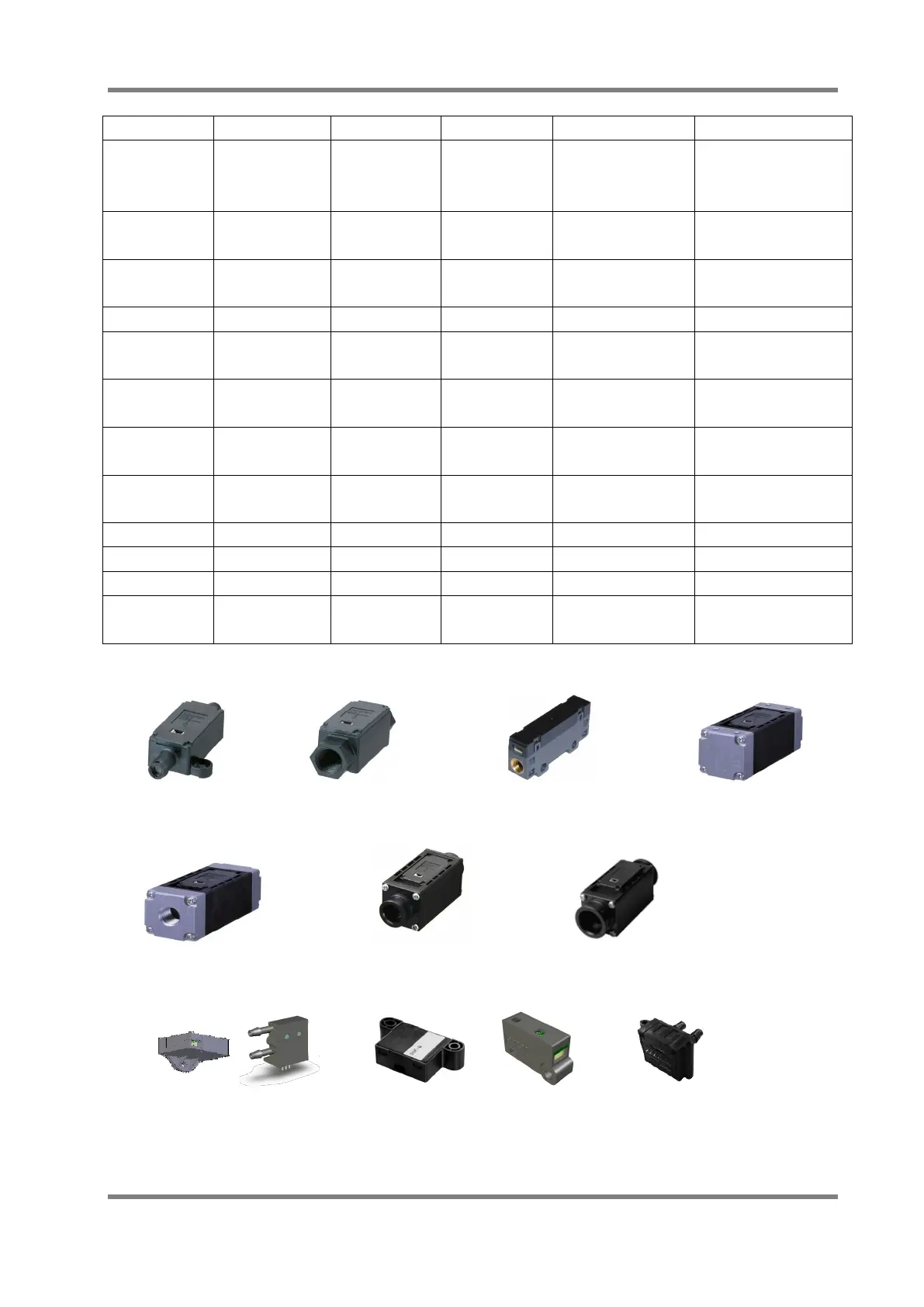

D6F-A1 D6F-□N2/-02L2 D6F-03A D6F-□A5

D6F-□□6 D6F-□□7 D6F-□AB7

D6F-P D6F-W D6F-V03A1 D6F-PH

Fig. 2 D6F Series

4 Operating principle

4.1 Basic structure of MEMS flow sensor chip

The basic structure of a MEMS flow sensor chip is shown in Fig.3. This sensor chip adopts a

Loading...

Loading...