4-21

4 System Design

G5 Series AC Servo Drives With Built-in EtherCAT Communications, Linear Motor Type

4-2 Wiring

4

4-2-2 Main Circuit and Linear Motor Connections

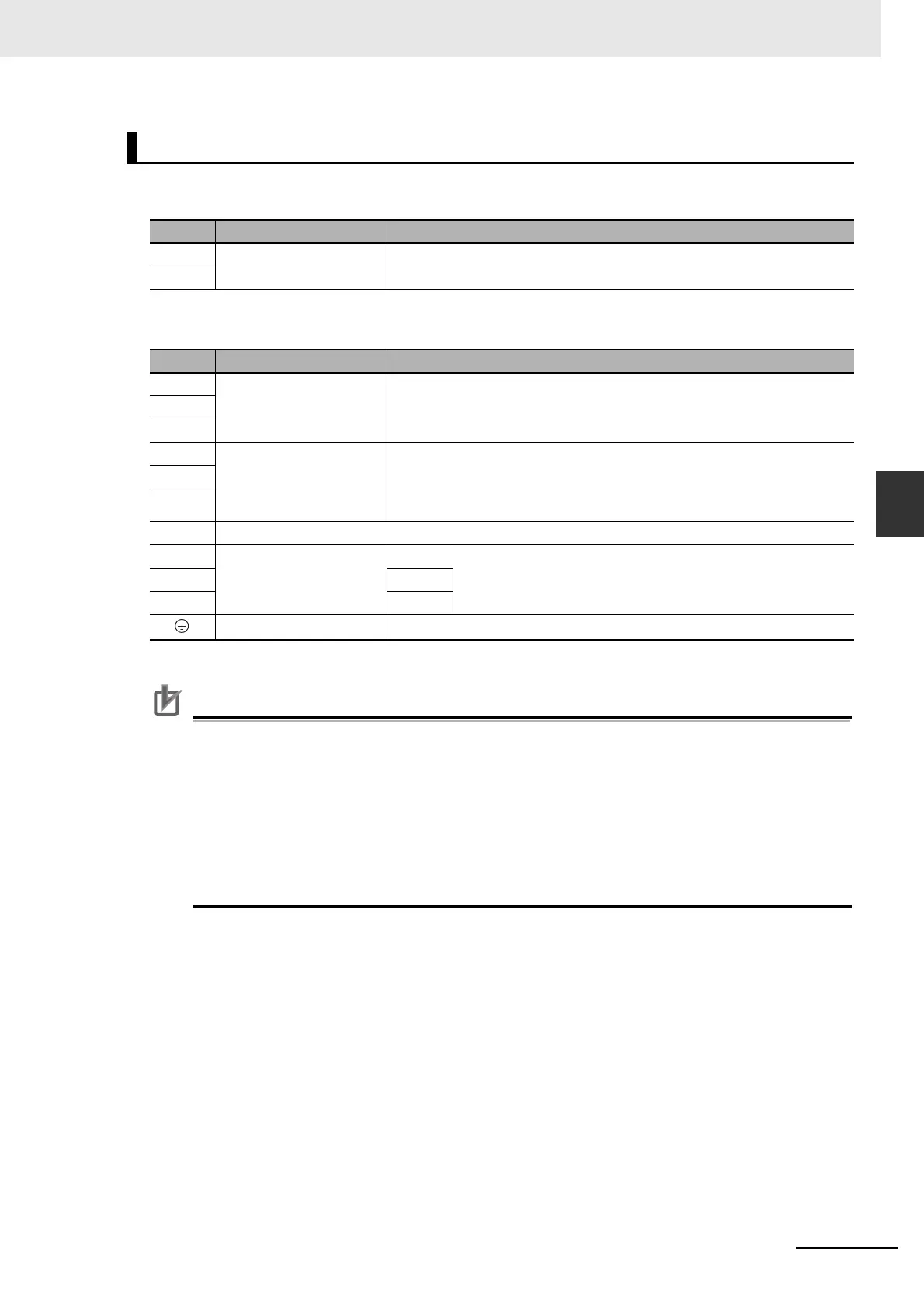

Control Circuit Terminal Block Specifications (TB1)

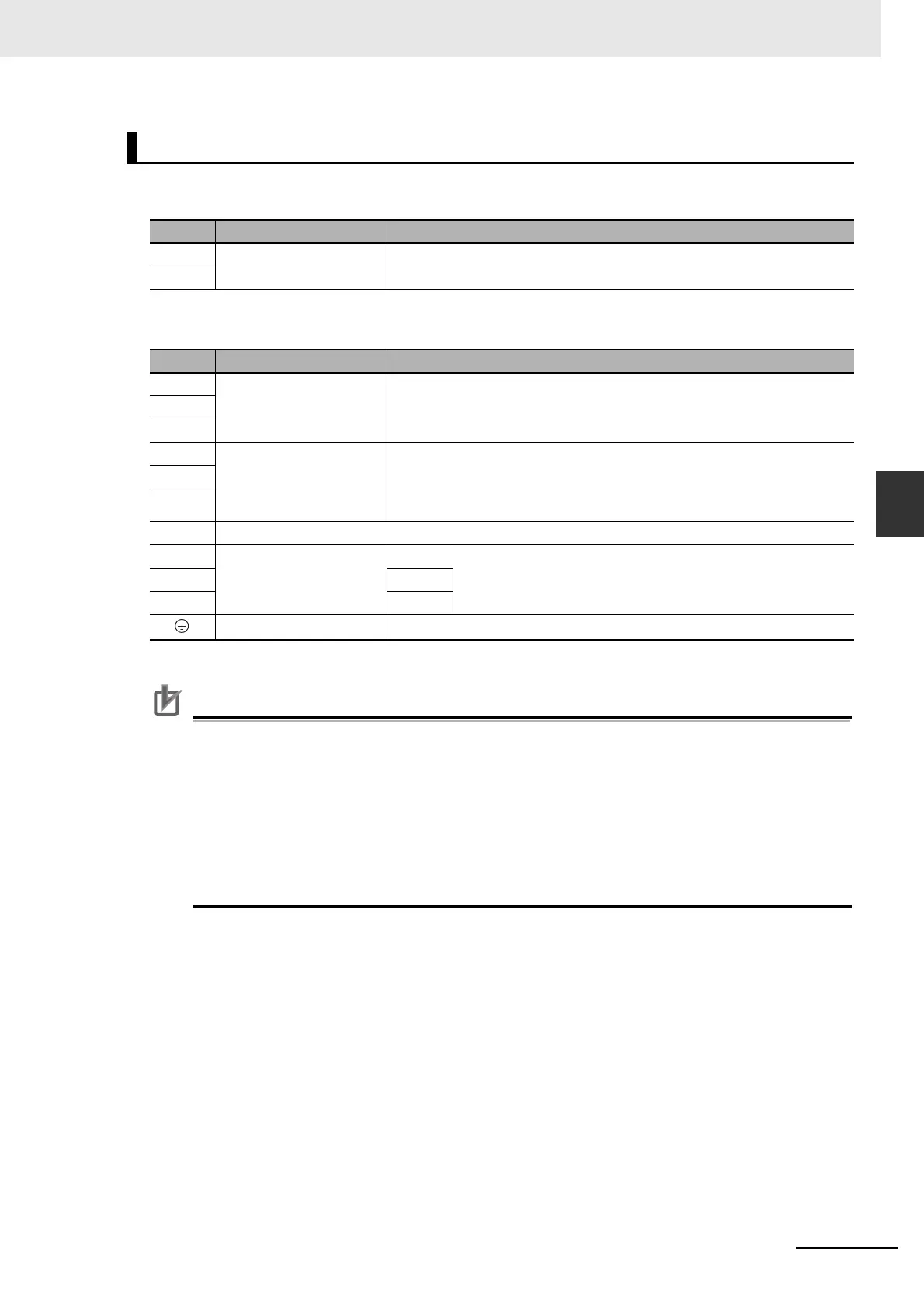

Main Circuit Terminal Block Specifications (TB2)

*1 Do not short B1 and B2. Doing so may result in malfunctioning.

Precautions for Correct UsePrecautions for Correct Use

• Tighten the frame ground screw to a torque of 1.4 to 1.6 N·m (M5).

• Tighten the 24 V terminal block screws to a torque of 0.4 to 0.6 N·m (M3).

• Tighten the terminal block screws to a torque of 0.7 to 1.0 N·m (M4). Exceeding the maximum

allowable torque for terminal block screws may cause damage to the terminal block.

• Tighten the fixing screw of the terminal block cover to a torque of 0.19 to 0.21 N·m (M3).

• If you are connecting an External Regeneration Resistor, set the Regeneration Resistor

Selection servo parameter object (3016 hex).

• Do not connect any External Regeneration Resistors between B1 and NC.

R88D-KN30F-ECT-L/-KN50F-ECT-L

Symbol Name Function

24 V Control circuit power

supply input

24 VDC (20.4 to 27.6 VDC)

0 V

Symbol Name Function

L1 Main circuit power supply

input

3-phase 380 to 480 VAC (323 to 528 VAC) 50/60 Hz

L2

L3

B1 External Regeneration

Resistor connection

terminals

*1

Normally short B2 and B3.

If there is high regenerative energy, remove the short-circuit bar between

B2 and B3 and connect an External Regeneration Resistor between B1

and B2.

B3

B2

NC Do not connect.

U Motor connection

terminals

Phase U These are the output terminals to the Linear Motor.

Be sure to wire them correctly.

V Phase V

W

Phase W

Frame ground This is the ground terminal. Ground to 100 or less.

Loading...

Loading...