A-155

Appendicies

G5 Series AC Servo Drives With Built-in EtherCAT Communications, Linear Motor Type

A-3 Sysmac Error Status Codes

App

A-3-2 Error Description

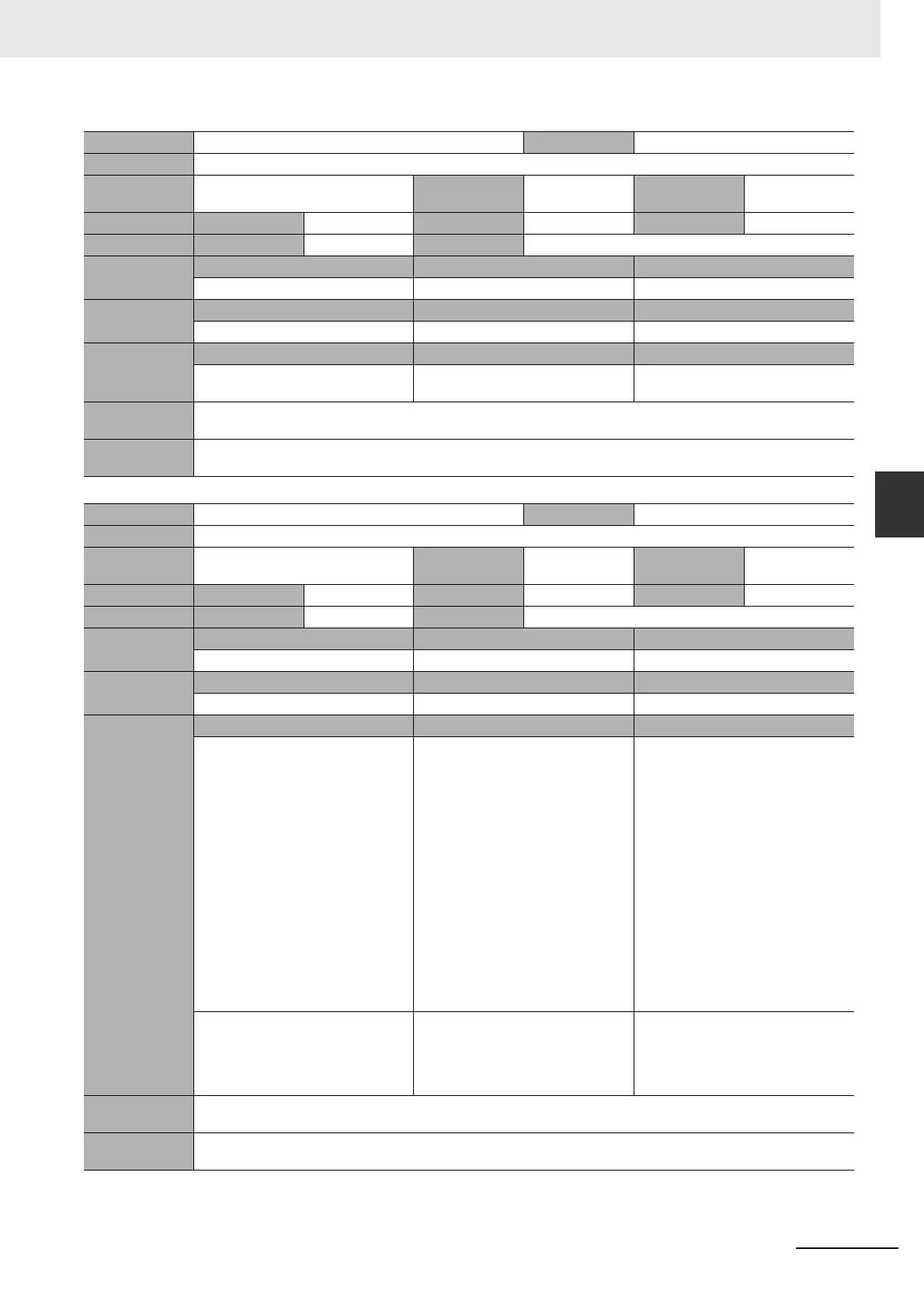

Event name Data Setting Warning Event code 34E00000 hex

Meaning An object setting is out of range.

Source EtherCAT Master Function Module Source details Slave Detection

timing

Continuously

Error attributes Level Observation Recovery --- Log category System

Effects User program Continues. Operation Not affected.

Indicators EtherNet/IP NET RUN EtherNet/IP NET ERR EtherNet/IP LINK/ACT

--- --- ---

System-defined

variables

Variable Data type Name

None --- ---

Cause and

correction

Assumed cause Remedy Prevention

An object setting is out of range. Correct the object settings so that

they are within the specified ranges.

Set the object settings so that they

are within the specified ranges.

Attached

information

None

Precautions/

Remarks

“B0” is displayed on the front panel of the Servo Drive.

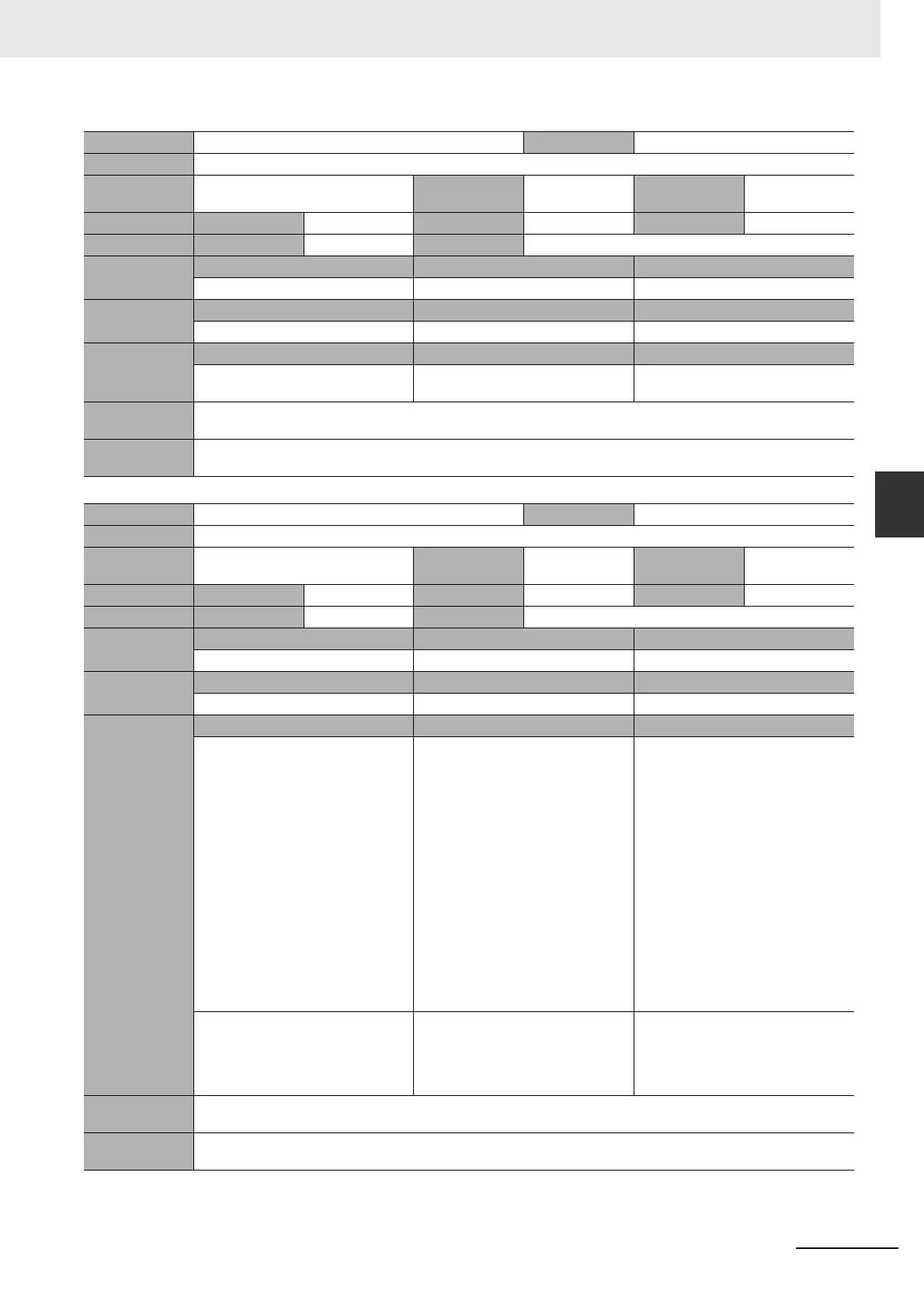

Event name Overload Warning Event code 383C0000 hex

Meaning The load ratio is 85% or more of the protection level.

Source EtherCAT Master Function Module Source details Slave Detection

timing

While power is

supplied to motor

Error attributes Level Observation Recovery --- Log category System

Effects User program Continues. Operation Not affected.

Indicators EtherNet/IP NET RUN EtherNet/IP NET ERR EtherNet/IP LINK/ACT

--- --- ---

System-defined

variables

Variable Data type Name

None --- ---

Cause and

correction

Assumed cause Remedy Prevention

Overload Take the following actions according

to the situation.

• Increase the capacities of the Servo

Drive and the motor.

• Increase the setting of the

acceleration/deceleration time and

lighten the load.

• Adjust the gain or mass ratio.

• Remove machine distortion.

• Measure the voltage at the brake

terminal. If the brake is ON, release

it.

• Correct the system if force (current)

waveforms oscillate or excessively

oscillate vertically during analog

output or communications.

Check the items given for corrections

in advance and implement

countermeasures as required.

There is incorrect wiring of the motor

line or a broken cable.

Connect the motor cable as shown in

the wiring diagram. If the cable is

broken, replace it. Connect the motor

line and external encoder line that are

used together to the same motor.

Connect the motor cable as shown in

the wiring diagram. Connect the

motor line and external encoder line

that are used together to the same

motor.

Attached

information

None

Precautions/

Remarks

“A0” is displayed on the front panel of the Servo Drive.

Loading...

Loading...