142

Section 6 Maintenance and Inspection

RFID System

Operation Manual

Section 6

Troubleshooting

Maintenance and Inspection

To keep the ID Controller in the best condition, the ID Controller should be inspected daily or periodically.

Although the ID Controller consists of semiconductor devices, the following problems may occur depending on the

environment and conditions in which the ID Controller is operated.

1. Degradation of elements due to overcurrents and overvoltages

2. Degradation of elements due to long-term stress caused by using ID Controller at high temperatures

3. Degradation of insulation and faulty connector contact due to humidity and dust

4. Faulty connector contact or corrosion due to corrosive gas

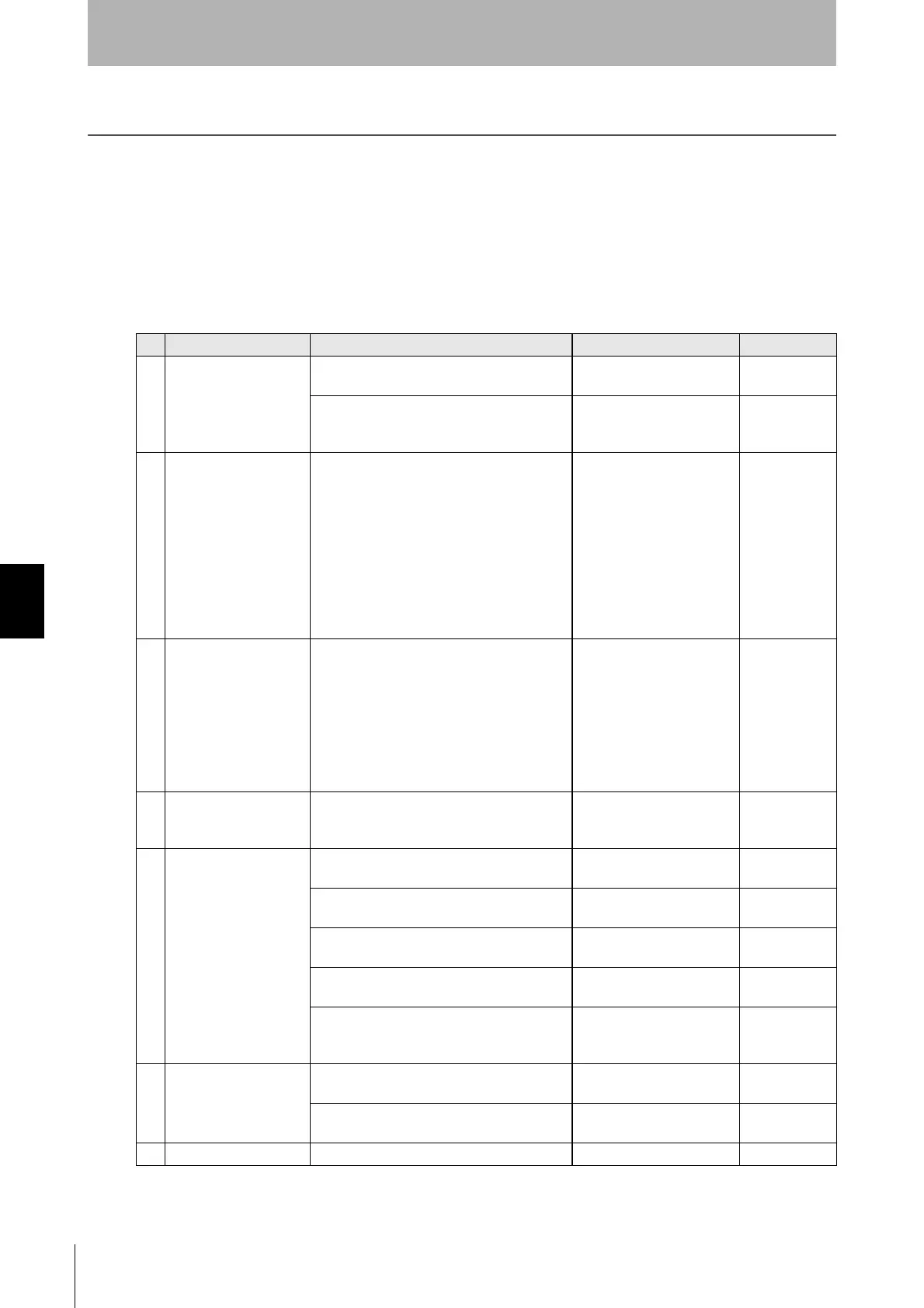

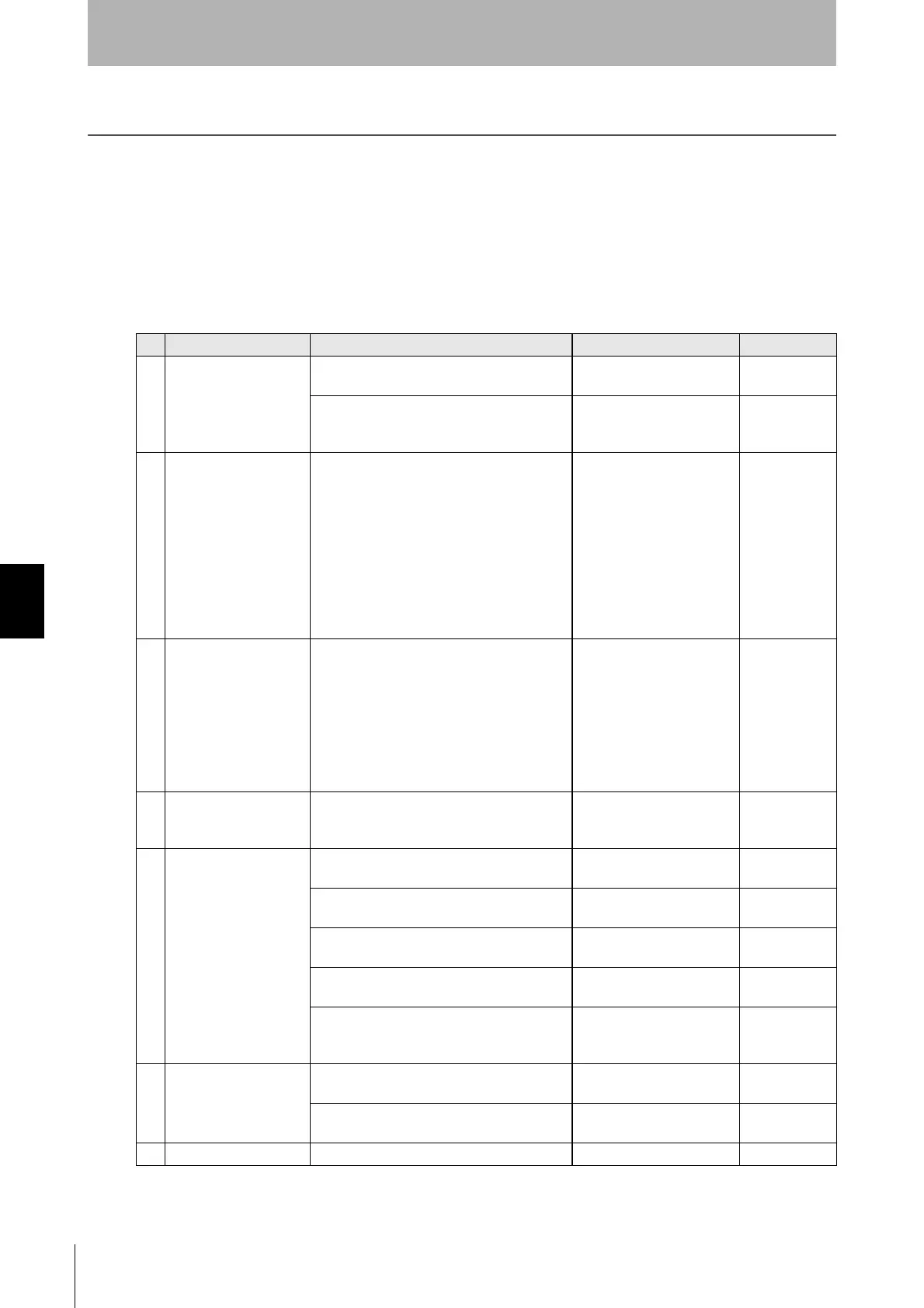

■ Inspection Items

No. Inspection item Details Criteria Remarks

1

Power supply voltage

fluctuations

1. Voltage measured at power supply terminal

block within rated range?

Supply voltage must be

within rated range.

Voltage tester

2. Momentary power failures occur fre-

quently? Abrupt rises in supply voltage

occur?

Supply voltage fluctuations

must be within rated range.

Power analyzer

2

Ambient conditions

Thermometer

and hygrometer

(a) Temperature (a) Must be within rated values. (a) 10 to 55C

(b) Humidity (b) Must be within rated values. (b) 25% to 85%

(c) Vibration and shock (c) Is vibration or shock being transmitted from

the equipment?

(c) Must be within ratings.

(d) Dust and dirt (d) Is dust, dirt, or foreign objects collecting on

the Controller?

(d) Must be free from dust,

dirt, and foreign objects.

(e) Corrosive gas (e) Are the metallic parts discolored or cor-

roded?

(d) Must be free from discol-

oration and corrosion.

3

Control Panel Condi-

tions

---

(a) Is ventilation good? (a) Is natural ventilation, forced ventilation, or

air conditioning adequate?

(a) Good ventilation is

essential. Temperature in

panel must be -10 to

55C.

(b) Is packing damaged

in a sealed panel?

(b) Is panel packing loose or damaged? (b) Packing must be free

from damage.

4

I/O power

(a) Voltage fluctuations

(b) Ripple

Is voltage measured at each I/O terminal

within rated level?

Supply voltage must be

within rated range.

Voltage tester

and oscillo-

scope

5 Mounting conditions

(1) Is each device mounted securely? There must be no loose-

ness.

---

(2) Are connectors inserted securely? Connectors must be locked

and tightened with screws.

---

(3) Are terminal block screws loose? There must be no loose

screws.

---

(4) Is the wiring damaged? Wiring must be free from

damage.

---

(5) Are the communications specifications

between Data Carrier and Read/Write

Head satisfied?

Specifications m

ust be

within rated ranges. ---

6

Data Carrier service life

confirmation

Check the manufacturing data of the Data

Carriers with built-in batteries.

The battery service life must

not be exhausted.

---

Check the overwrite count of Data Carriers

without batteries.

The overwrite count must

not exceed the limit.

---

7 Error log check Check the error log --- ---

Loading...

Loading...