SCALE.

GROUND

ON

MOTOR

AT

POINT

FREE

OF

GREASE

AND

PAINT

KNIFE

SWITCH

STORAGE

BATTERY

RESISTANCE

POSITION

OF j

BRAKE

ARM

-12"

STARTING

MOTOR

O

o

o

o

o

o

FIGURE

30.

TESTING

STALL

TORQUE

If

starting motor tests

are

required, remove

the

motor

from

the

engine

and

test

it on a

bench. Test

the

free

running voltage

and

current. Limits

are

given.

in the

Dimensions

and

Clearances Section.

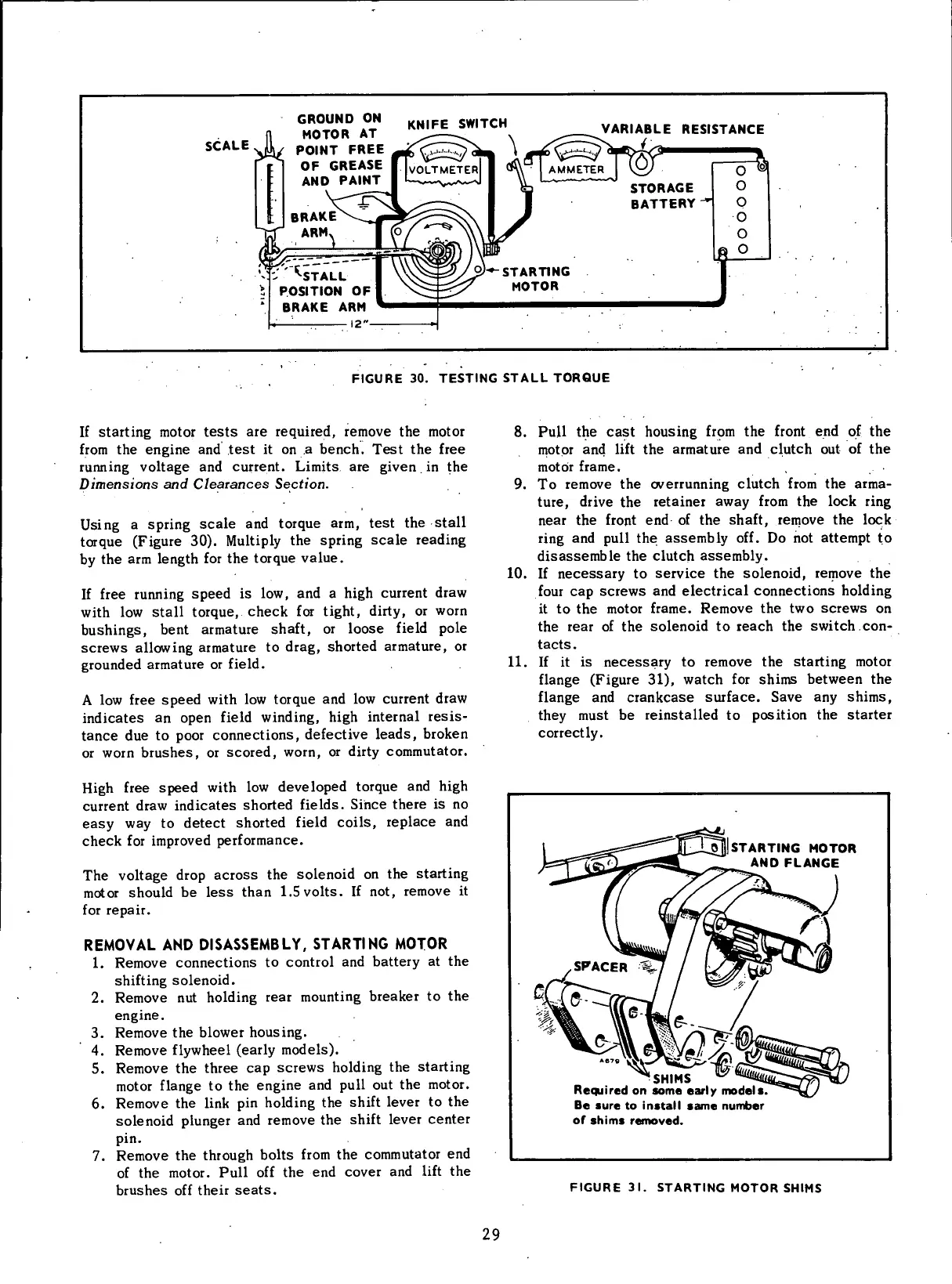

Using

a spring

scale

and torque arm, test the

stall

torque (Figure 30).

Multiply

the spring

scale

reading

by

the arm length for the torque value.

If

free running

speed

is low, and a

high

current draw

with

low

stall

torque, check for

tight,

dirty,

or

worn

bushings, bent armature shaft, or loose

field

pole

screws

allowing

armature to drag, shorted armature, or

grounded armature or

field.

A

low free

speed

with

low torque and low current draw

indicates an open

field

winding,

high

internal resis-

tance

due to poor connections, defective leads, broken

or

worn

brushes, or scored,

worn,

or

dirty

commutator.

High

free

speed

with

low developed torque and

high

current

draw indicates shorted

fields.

Since there is no

easy

way to detect shorted

field

coils,

replace and

check for improved performance.

The voltage drop

across

the solenoid on the starting

motor

should be

less

than 1.5

volts.

If not, remove it

for

repair.

REMOVAL

AND

DISASSEMBLY,

STARTING

MOTOR

1.

Remove connections to

control

and battery at the

shifting

solenoid.

2.

Remove nut

holding

rear mounting breaker to the

engine.

3. Remove the blower housing.

4.

Remove

flywheel

(early models).

5. Remove the three cap screws

holding

the starting

motor

flange to the engine and

pull

out the motor.

6. Remove the

link

pin

holding

the

shift

lever to the

solenoid

plunger and remove the

shift

lever center

pin.

7. Remove the through bolts

from

the commutator end

of

the motor.

Pull

off the end cover and

lift

the

brushes

off their

seats.

8.

Pull

the

cast

housing

frpm

the

front

end of the

motor

and

lift

the armature and

clutch

out of the

motor

frame.

9. To remove the overrunning

clutch

from

the arma-

ture,

drive the retainer away

from

the

lock

ring

near

the

front

end of the shaft, remove the

lock

ring

and

pull

the assembly off. Do not attempt to

disassemble the

clutch

assembly.

10.

If

necessary

to service the solenoid, remove the

four

cap screws and electrical connections

holding

it

to the motor frame. Remove the two screws on

the rear of the solenoid to reach the

switch

.con-

tacts.

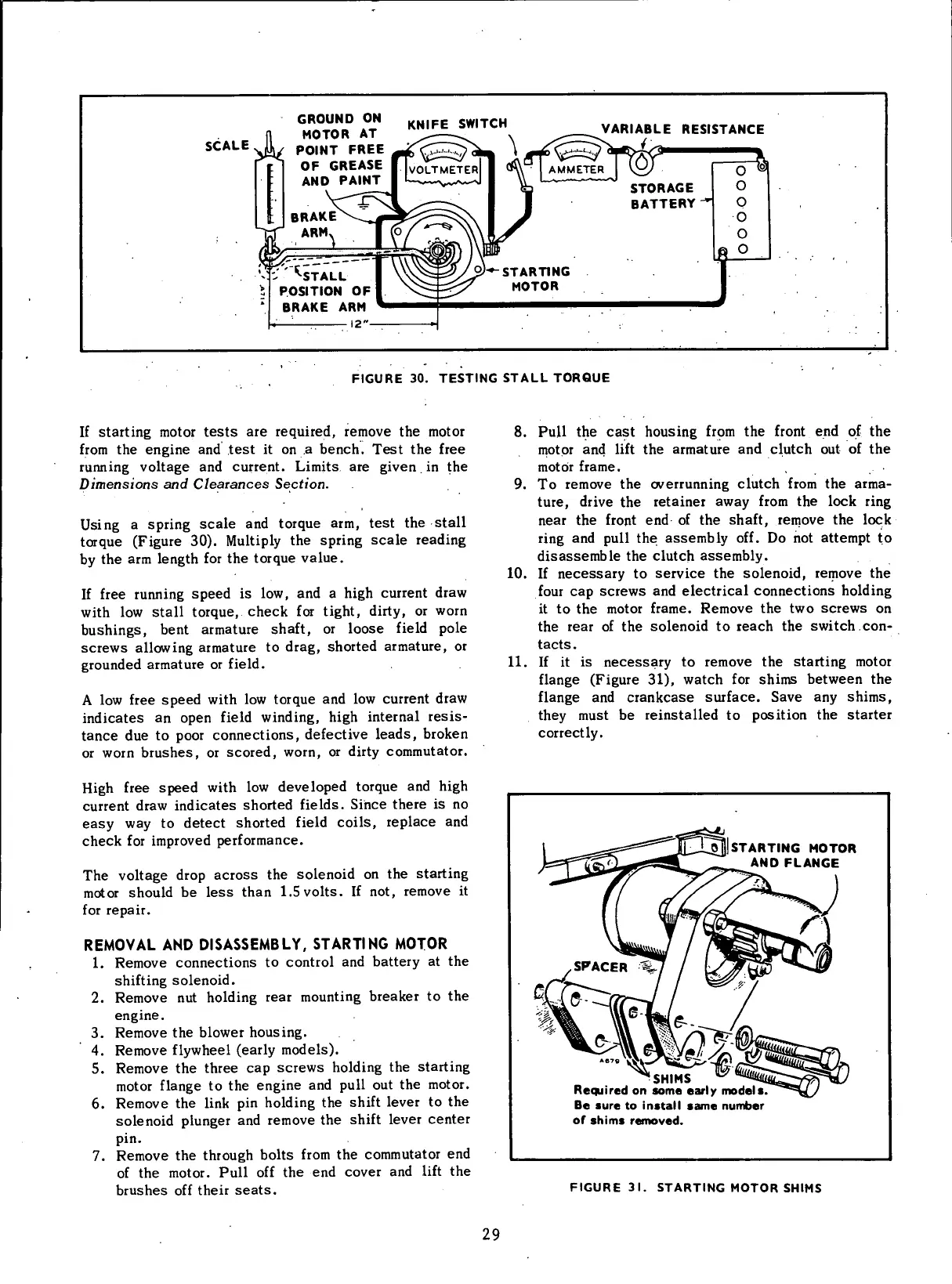

11.

If it is

necessary

to remove the starting motor

flange

(Figure 31), watch for shims between the

flange

and crankcase surface.

Save

any shims,

they must be reinstalled to position the starter

correctly.

STARTING

MOTOR

AND FLANGE

'SHIMS

Required

on

some

early

models.

Be

sure

to

install

same

number

of

shims

removed.

FIGURE

31.

STARTING

MOTOR

SHIMS

29

Loading...

Loading...